You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

12VDC and system (battery and Solar) needed for wood stove exhaust extraction blower

- Thread starter Get1949

- Start date

Get1949

New Member

- Joined

- Dec 2, 2021

- Messages

- 45

Testing was not done in the summer--but you're right. But I also do not need much negative (venturi) pressure across the SS pipe end. And the hot pipe is insulated and will be less than about 9 feet long and most of the inside...seeing as how I'm using cold air for the driving effect of venturi I then need the necking down diameters (increasing velocity and decreasing pressure) go across the stainless steel (SS) exhaust pipe end drafting out the hot SS 'air'...it then dumps to the atmosphere about 12 inches further...so no hot heat issues should be involved with any of the connections or fan or electrical all being separated from heat. If you look up "extractor cones" "eductor pump, eductor venturi, eductor nozzle, eductor tee" then you'll probably learn a new word as I have never heard the term EDUCTOR (and yes that is spelled correctly!)Be mindful drafts are dramatically impacted by exhaust temps. By injecting cold dense air to a weak draft, it may counter any Venturi effect.

Testing in the summer of a doesn’t reflect when temps are in the teens.

Rednecktek

Solar Wizard

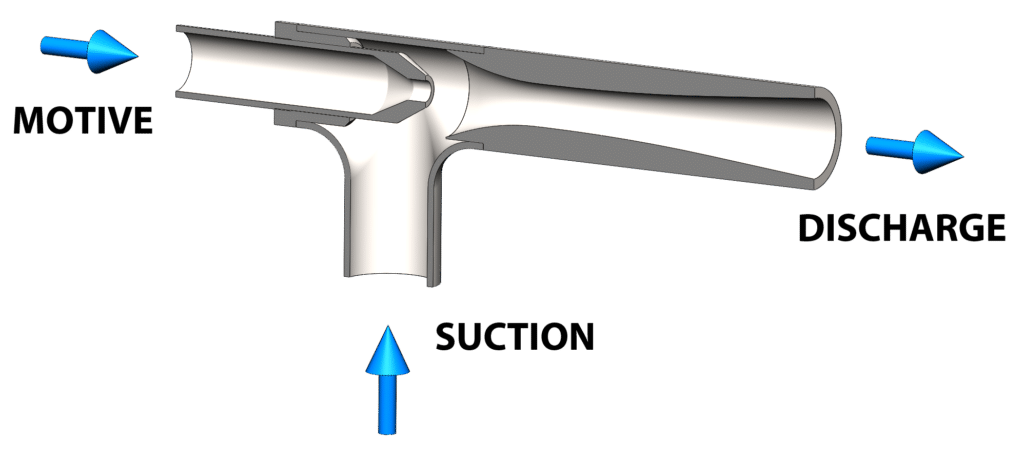

Now THAT makes sense! Fan at the Motive and Discharge points? Smoke comes up from the Suction end? I don't think the fan at the Discharge point is really buying you anything other than smoke in the fan bearings.

Get1949

New Member

- Joined

- Dec 2, 2021

- Messages

- 45

YUP!!!Now THAT makes sense! Fan at the Motive and Discharge points? Smoke comes up from the Suction end?

Get1949

New Member

- Joined

- Dec 2, 2021

- Messages

- 45

The FAN is mounted at the MOTIVE end and blow through to the DICHARGE end and across the SUCTION Tee lifting the exhaust gases from the SUCTION end and blowing them out the DISCHARGE so the fan NEVER gets hot nor the bearing cookedNow THAT makes sense! Fan at the Motive and Discharge points? Smoke comes up from the Suction end? I don't think the fan at the Discharge point is really buying you anything other than smoke in the fan bearings.

Get1949

New Member

- Joined

- Dec 2, 2021

- Messages

- 45

I also do not believe it needs to be so perfectly built. All the examples of eductors are for water movement and control especially in (large) fish tanks and also most are PVC or are very expensive in gasoline and oil production and being stainless steel HUGE things. I can not use one that is PVC as that would melt but HVAC ducting would be OK. I just need a way to fabricate the sheet metal...and that's going to slow medown...in a CONDO arrangement!! ha ha ha

Get1949

New Member

- Joined

- Dec 2, 2021

- Messages

- 45

Check this link out: https://www.foxvalve.com/liquid-eductors/introduction/ I also seem to remember a web on you tube called "rollation" in which this guy shows how to make sheetmetal cones and reducers and making round ends to join into a square end all with sheetmetal and most of this done at home in the garage--or small shop. Going from the picture of the MOTIVE SUCTION and DISCHARGE pipe at the left end the MOTIVE fan would blow forced air INTO a 6 X 4 x 2 inch reduction unit (sheetmetal) in which IT is inserted into a 6 inch straight pipe. The air would increase in velocity exiting the 2 inch end of the reducer and blowing that fast air across the 4 inch SS pipe Tee fitted into the surrounding 6 inch straight pipe (causing vacuum) and then all that goes out the DISCHARGE end of the straight 6 inch pipe end. The Fan is attached at the far left of the 6 inch reducer (the reducer is inserted into the surrounding 6 inch straight pipe BACKWARDS so that the 2 inch end is INSIDE the enveloping straight pipe... It's crude but it all does not need to function perfectly...it's MacGyver thing...just need enough negitive SUCTION to vent/draft the stove

Get1949

New Member

- Joined

- Dec 2, 2021

- Messages

- 45

Hi, all you solar geeks... I'm back...

I believe I now have my duct fans and duct arrangements correct enough to give me a sufficient venturi (eductor) effect to draw the exhaust gases from my wood stove (especially when opening the stove to feed it wood). The arrangements are two-fold (two different ways) all using 12-volt DC duct (marine bilge pump gas extraction) fans: One arrangement has two 12V, 2.5 amps fans (each rated with for a 5-amp fuse) the other uses one 12V, 6-amp duct fan (10.0-amp fuse). I experimented by using an AC/DC converter with a rheostat so that I could control the CFM speed (this allowed me to find the lowest fan speed/CFM which would still draw a flame from the wood stove exhaust pipe). Of course, I did not fire-up the wood stove just to test this but instead assembled the two styles of duct arrangements (on my floor) so that a same size exhaust pipe could be inserted into the fan duct (area) and so placed that its high-speed fan air was blown over the top of the exhaust pipe… this caused a vacuum which pulled air from the (wood stove) exhaust pipe and into an expanded diameter duct and out to the atmosphere. I lit a small can of sterno cook gel right in its can and placed it near the other end of the inserted exhaust pipe (which was in the duct fan high velocity air)—the sterno can represented the wood stove. With the sterno lit and the fan(s) powered I was able to suck the air, fumes and flame from the sterno can and into the pipe and blast it out the far end of the duct. No hot air goes through the fans…cold air rather goes over the hot pipe end. The exact angle and shape of the pipe end at the location of the high-speed air from the fans seems yet to be determined but what few different pipe ends/shapes I was able to make (or angles inserted) into the air stream seems to give the same results of vacuum draw on the wood stove pipe.

MY NEXT NEED is what to get for the best type and rating (voltage and amperage) of solar panels and supporting equipment (wiring and batteries etc etc) to power these fans. So, I welcome your suggestions and ideas! Most of the equipment will be located on a porch (semi-protected from rain) but everything would be cold (putting the battery inside a Styrofoam container… I have a good large one… is totally doable and was a good idea suggested previously). The panels still should be nearly water-proof (least I not able to get them inside quick enough and the way they will need to be hung from off the porch railing would mean I’d need time to take them down). All the controls would be located inside and near the ‘cold’ make-up air for the front of the wood stove but the duct fans would be outside (they are marine bilge pump fans and would be waterproof and also, I intend to bag them making them further safe from any direct water). MacGyver…would be proud! So what do you all suggest for Panels and… stuff? Thanks

I believe I now have my duct fans and duct arrangements correct enough to give me a sufficient venturi (eductor) effect to draw the exhaust gases from my wood stove (especially when opening the stove to feed it wood). The arrangements are two-fold (two different ways) all using 12-volt DC duct (marine bilge pump gas extraction) fans: One arrangement has two 12V, 2.5 amps fans (each rated with for a 5-amp fuse) the other uses one 12V, 6-amp duct fan (10.0-amp fuse). I experimented by using an AC/DC converter with a rheostat so that I could control the CFM speed (this allowed me to find the lowest fan speed/CFM which would still draw a flame from the wood stove exhaust pipe). Of course, I did not fire-up the wood stove just to test this but instead assembled the two styles of duct arrangements (on my floor) so that a same size exhaust pipe could be inserted into the fan duct (area) and so placed that its high-speed fan air was blown over the top of the exhaust pipe… this caused a vacuum which pulled air from the (wood stove) exhaust pipe and into an expanded diameter duct and out to the atmosphere. I lit a small can of sterno cook gel right in its can and placed it near the other end of the inserted exhaust pipe (which was in the duct fan high velocity air)—the sterno can represented the wood stove. With the sterno lit and the fan(s) powered I was able to suck the air, fumes and flame from the sterno can and into the pipe and blast it out the far end of the duct. No hot air goes through the fans…cold air rather goes over the hot pipe end. The exact angle and shape of the pipe end at the location of the high-speed air from the fans seems yet to be determined but what few different pipe ends/shapes I was able to make (or angles inserted) into the air stream seems to give the same results of vacuum draw on the wood stove pipe.

MY NEXT NEED is what to get for the best type and rating (voltage and amperage) of solar panels and supporting equipment (wiring and batteries etc etc) to power these fans. So, I welcome your suggestions and ideas! Most of the equipment will be located on a porch (semi-protected from rain) but everything would be cold (putting the battery inside a Styrofoam container… I have a good large one… is totally doable and was a good idea suggested previously). The panels still should be nearly water-proof (least I not able to get them inside quick enough and the way they will need to be hung from off the porch railing would mean I’d need time to take them down). All the controls would be located inside and near the ‘cold’ make-up air for the front of the wood stove but the duct fans would be outside (they are marine bilge pump fans and would be waterproof and also, I intend to bag them making them further safe from any direct water). MacGyver…would be proud! So what do you all suggest for Panels and… stuff? Thanks

Rednecktek

Solar Wizard

So what did you find was the lowest setting for the fans amperage wise?

Solar panels are designed to be out in the weather, I wouldn't worry about keeping them dry as long as your connections are waterproof you should be fine.

Your notes say you've got about 6a of fan draw which is a LOT if you can't slow them down quite a bit. Just some napkin math using the Wally World 120Ah Deep Cycle batteries that gives you about 10 hours of run time per battery and you'll need at least a 100w panel AND 3+ hours of really good sun to top them off in a day. 200w would be better and it's easy to do.

Is that Styrofoam container one of the cheap white ones or is it an actual cooler? If it's a cooler then pick up a roll of rubber weather strip for the lid and that should solve your weatherproofing issues just fine. If it's the cheapie white ones, craigslist for a cooler with a hinged lid.

Some simple angle iron with holes and a couple bolts can make legs to help push the bottom of the panels away from the railing so you can get a good angle to the sun. Straight up and down isn't going to do you much good, you'll take a pretty significant production hit.

Sounds like you're coming along nicely!

Solar panels are designed to be out in the weather, I wouldn't worry about keeping them dry as long as your connections are waterproof you should be fine.

Your notes say you've got about 6a of fan draw which is a LOT if you can't slow them down quite a bit. Just some napkin math using the Wally World 120Ah Deep Cycle batteries that gives you about 10 hours of run time per battery and you'll need at least a 100w panel AND 3+ hours of really good sun to top them off in a day. 200w would be better and it's easy to do.

Is that Styrofoam container one of the cheap white ones or is it an actual cooler? If it's a cooler then pick up a roll of rubber weather strip for the lid and that should solve your weatherproofing issues just fine. If it's the cheapie white ones, craigslist for a cooler with a hinged lid.

Some simple angle iron with holes and a couple bolts can make legs to help push the bottom of the panels away from the railing so you can get a good angle to the sun. Straight up and down isn't going to do you much good, you'll take a pretty significant production hit.

Sounds like you're coming along nicely!

Get1949

New Member

- Joined

- Dec 2, 2021

- Messages

- 45

Aaaah, I did not think to measure amperage (that's a dumb on my part... Duhhhh!) what I did was to estimate the setting on the rheostat to max CFM and half and other knob angles on the rheostat as divisions of less than max CFM. It is correct isn't it, that if a fan pulls 6 amps at 270 CFM then at half that knob setting (from full) then at 135 CFM the amperage would be about 3 amps? Am I off on that 'logic'?! I have both options for the Styrofoam and naturally for the angle iron and mounting. If I get 24 volt solar panels and then a battery to take that then using only the 12 volts doesn't that give me twice for using the 24 volt battery and solar panels...I just have to select my voltage controller to 12 rather than 24 (don't want to blow up the fans!). I'm not too restraint for funds ($$) so if you think of an arrangement (and with your helpful links) then I'll certainly go check it all out. I suppose Will Prowers has some systems?!So what did you find was the lowest setting for the fans amperage wise?

Solar panels are designed to be out in the weather, I wouldn't worry about keeping them dry as long as your connections are waterproof you should be fine.

Your notes say you've got about 6a of fan draw which is a LOT if you can't slow them down quite a bit. Just some napkin math using the Wally World 120Ah Deep Cycle batteries that gives you about 10 hours of run time per battery and you'll need at least a 100w panel AND 3+ hours of really good sun to top them off in a day. 200w would be better and it's easy to do.

Is that Styrofoam container one of the cheap white ones or is it an actual cooler? If it's a cooler then pick up a roll of rubber weather strip for the lid and that should solve your weatherproofing issues just fine. If it's the cheapie white ones, craigslist for a cooler with a hinged lid.

Some simple angle iron with holes and a couple bolts can make legs to help push the bottom of the panels away from the railing so you can get a good angle to the sun. Straight up and down isn't going to do you much good, you'll take a pretty significant production hit.

Sounds like you're coming along nicely!

Rednecktek, If you don't mind my asking where are you in the states that you get sun (angle) I'm in western Massachusetts--so I'll need solar panels in bunches to make up for my latitude and weather...!?

circus

Solar Enthusiast

- Joined

- Jul 8, 2021

- Messages

- 380

Far be it I discourage inventiveness but all your problems would be solved with a $120 kerosene heater. Easily heats 800 sq ft 14 hours on a gallon of kerosene. When tuned has no smell. No electricity. There's awful wood burning boilers that spew out cold smoke that hangs low to the ground. Always downwind of the home owner but gasses the neighbors. When I bike pass my eyes sting.

Last edited:

Rednecktek

Solar Wizard

OK, a couple thoughts:

There's no such thing as a "12v panel" or a "24v panel", it's just a marketing term to represent "Would create enough voltage to charge a 12v battery" or "charge a 24v battery" so don't worry about that. The big thing you're going to want to pay attention to is the VoC rating for each panel.

The sun angle is based on latitude, and the PVWatts can give you the best angle for each month because the sun isn't as high in the sky in winter as it is in summer. As a rule of thumb latitude = angle for general all 'round performance. You'll want the sun perpendicular to the panels as much as possible for optimum performance.

As for what to get, 100w panels are a handy size to move around but are the highest cost per watt. If you can swing it, you might want to look at a 400w panel or so that will fit on the porch, or a way to hang a couple 200w panels, or 4 of the 100w panels. It all comes down to what you can physically fit over the rail. Since you're running a 12v system, 800w (12v * 60a = 720w) is pretty much the maximum you can utilize. Usually 1x 400w panel is physically smaller than 4x 100w panels, so tape measure time!

You'll want your panels, a nice (Victron, EPEver, etc) 60a MPPT controller, the batteries, fuses, and a shunt monitor. The MPPT controller will let you utilize the panels more efficiently for more power through the day and in lower light situations like cloudy days. Since you're running this all off of 12v there's no need for an inverter, it sounds like everything you need is either 12v or USB and there are LOTS of USB options out there. The shunt monitor (the Ail's are a popular choice) will tell you things like how much battery you have left, how much you're drawing, how much you're charging, etc. The display is connected via a small cable so you could mount the monitor right in the side of the cooler so you can see it at a glance, or run it to your "control board" by the fire that has the rheostats. Wire can go pretty much anywhere.

Your amperage guessing is about right for paper, but power is a bit logarithmic so if your 6a draw is about half-way on the dial, you're probably closer to 2.5a than 3a. That's where the shunt display comes in handy too.

@circus: Yeah, ideas like that have been covered but fuel storage is an issue and he's trying to "Make a project work" as much for fun as functionality.

There's no such thing as a "12v panel" or a "24v panel", it's just a marketing term to represent "Would create enough voltage to charge a 12v battery" or "charge a 24v battery" so don't worry about that. The big thing you're going to want to pay attention to is the VoC rating for each panel.

The sun angle is based on latitude, and the PVWatts can give you the best angle for each month because the sun isn't as high in the sky in winter as it is in summer. As a rule of thumb latitude = angle for general all 'round performance. You'll want the sun perpendicular to the panels as much as possible for optimum performance.

As for what to get, 100w panels are a handy size to move around but are the highest cost per watt. If you can swing it, you might want to look at a 400w panel or so that will fit on the porch, or a way to hang a couple 200w panels, or 4 of the 100w panels. It all comes down to what you can physically fit over the rail. Since you're running a 12v system, 800w (12v * 60a = 720w) is pretty much the maximum you can utilize. Usually 1x 400w panel is physically smaller than 4x 100w panels, so tape measure time!

You'll want your panels, a nice (Victron, EPEver, etc) 60a MPPT controller, the batteries, fuses, and a shunt monitor. The MPPT controller will let you utilize the panels more efficiently for more power through the day and in lower light situations like cloudy days. Since you're running this all off of 12v there's no need for an inverter, it sounds like everything you need is either 12v or USB and there are LOTS of USB options out there. The shunt monitor (the Ail's are a popular choice) will tell you things like how much battery you have left, how much you're drawing, how much you're charging, etc. The display is connected via a small cable so you could mount the monitor right in the side of the cooler so you can see it at a glance, or run it to your "control board" by the fire that has the rheostats. Wire can go pretty much anywhere.

Your amperage guessing is about right for paper, but power is a bit logarithmic so if your 6a draw is about half-way on the dial, you're probably closer to 2.5a than 3a. That's where the shunt display comes in handy too.

@circus: Yeah, ideas like that have been covered but fuel storage is an issue and he's trying to "Make a project work" as much for fun as functionality.

Get1949

New Member

- Joined

- Dec 2, 2021

- Messages

- 45

Hi, Circus... I have not seen such a kerosene heater as you have supplied a picture of (do you have a link?). I do have a Dyna-Glo 23,000BTU... It's a big white cylinder looking thing and it holds 1.9 gallons of K-1 Klean Heat kerosene (and I have some of it stored!). Instructions state it will burn for two hours. I fired it up in my friends barn and it did OK but it does smell and it does need make-up air (which I have for the woodstove so that's a moot point). The thing that concerns me is the storage of the fuel. If I spill it and it soaks up into the carpet then I'm screwed...it does not evaporate enough that I could get it out of the condo unit...and seeing as how it is more flammable when in a medium of a wicking material--such as the carpet ...I'd really be pushing the envelope on fire danger. I realize that the wick in any such stove needs to be adjusted to burn cleanly (that is, adjusting the wick height is not done to regulate the amount of heat but only to make for more complete burning of the fuel and less combustion agents inside the living area). getting back to spill mistakes: I would have to rip up the carpet and toss it out...as the danger would be too high otherwise, also pouring the fluid is a real difficult task (I have it in mind that I put the unit in a big aluminum pan used for collecting water spill from a water heater and then if I miss pour the fluid it will end up in the aluminum pan for me to sop up with paper towels). I also have a Mr. Buddy Heater (Propane) and have tested that in my friends barn...that also works fair and storage of the little 1lb bottles (in my mind) is safer than the K-1 mainly because I have wrapped each propane bottle in its own zip-lock bag and then stored them in a large cooler like container with a sealed-lid. All the product is in my bedroom (meaning if there is a leak I will smell it...and besides everyone of them would need to 'pop' to gas me out of air while I sleep...and that's too far fetched to happen). And I do not heat my bedroom with the electric baseboard heater...ever. so there is no flammability issue there. I guess you're about to say I should move out of the condo and get a house with a barn and become more like the Canadian Prepper (seen on youtube) ha ha ha, and I would but for I'm now too old to take care of such a building and also I'm prior military and do not have the funds.... Thanks for your response though...Far be it I discourage inventiveness but all your problems would be solved with a $120 kerosene heater. Easily heats 800 sq ft 14 hours on a gallon of kerosene. When tuned has no smell. No electricity. There's awful wood burning boilers that spew out cold smoke that hangs low to the ground. Always downwind of the home owner but gasses the neighbors. When I bike pass my eyes sting.

View attachment 76426

Get1949

New Member

- Joined

- Dec 2, 2021

- Messages

- 45

Right on... Rednecktek!! As my ICON indicates... I'm a geek with my fingers in my ears waiting for (now, not the explosion but rather) the implosion of the country ha ha haOK, a couple thoughts:

There's no such thing as a "12v panel" or a "24v panel", it's just a marketing term to represent "Would create enough voltage to charge a 12v battery" or "charge a 24v battery" so don't worry about that. The big thing you're going to want to pay attention to is the VoC rating for each panel.

The sun angle is based on latitude, and the PVWatts can give you the best angle for each month because the sun isn't as high in the sky in winter as it is in summer. As a rule of thumb latitude = angle for general all 'round performance. You'll want the sun perpendicular to the panels as much as possible for optimum performance.

As for what to get, 100w panels are a handy size to move around but are the highest cost per watt. If you can swing it, you might want to look at a 400w panel or so that will fit on the porch, or a way to hang a couple 200w panels, or 4 of the 100w panels. It all comes down to what you can physically fit over the rail. Since you're running a 12v system, 800w (12v * 60a = 720w) is pretty much the maximum you can utilize. Usually 1x 400w panel is physically smaller than 4x 100w panels, so tape measure time!

You'll want your panels, a nice (Victron, EPEver, etc) 60a MPPT controller, the batteries, fuses, and a shunt monitor. The MPPT controller will let you utilize the panels more efficiently for more power through the day and in lower light situations like cloudy days. Since you're running this all off of 12v there's no need for an inverter, it sounds like everything you need is either 12v or USB and there are LOTS of USB options out there. The shunt monitor (the Ail's are a popular choice) will tell you things like how much battery you have left, how much you're drawing, how much you're charging, etc. The display is connected via a small cable so you could mount the monitor right in the side of the cooler so you can see it at a glance, or run it to your "control board" by the fire that has the rheostats. Wire can go pretty much anywhere.

Your amperage guessing is about right for paper, but power is a bit logarithmic so if your 6a draw is about half-way on the dial, you're probably closer to 2.5a than 3a. That's where the shunt display comes in handy too.

@circus: Yeah, ideas like that have been covered but fuel storage is an issue and he's trying to "Make a project work" as much for fun as functionality.

Get1949

New Member

- Joined

- Dec 2, 2021

- Messages

- 45

Nice reply, Rednecktek. Lots for me to think about...and I admit I'm not solar savvy but very solar curious. With all you mentioned I have also been looking at Will Prowers you tube videos (I believe he is really into all the solar stuff... and that's an understatement! ?Right on... Rednecktek!! As my ICON indicates... I'm a geek with my fingers in my ears waiting for (now, not the explosion but rather) the implosion of the country ha ha ha

circus

Solar Enthusiast

- Joined

- Jul 8, 2021

- Messages

- 380

Yea, I have one rusting in storage. The radiant style is better. Smaller. Fuel tank comes out for refueling. 18 hours per fill. Fuel level, the wick is in, doesn't change as the fuel is consumed making periodic adjustment unnecessary. Of course lighting, extinguishing and refueling would be done outside on the small balcony. I don't own the model shown but my 30 year old heater is similar.I do have a Dyna-Glo 23,000BTU..

Kerosene heater Waupun

PS I just looked at the ad. Don't use diesel!!! Around here they sell K1 (kerosene) out of the pump for $4.00 a gal. As for refueling, a cheap syphon pump is included. When fuel shows in the sight window on the tank you open the vent on the pump stopping the syphon. I've never spilt a drop.

Last edited:

Similar threads

- Replies

- 0

- Views

- 281

- Replies

- 4

- Views

- 630

- Replies

- 7

- Views

- 574

- Replies

- 34

- Views

- 734

- Replies

- 19

- Views

- 1K