Ok so if it's a USA 240v only load, like my water heater or heat pumps then it's no problem but for dual 120/240 loads it's a big no no? I think I'm tracking.In North American equipment the L1 and L2 are isolated from ground. For a simple element water heater, it probably wouldn't matter. For most other equipment (with electronics or control circuits) it would be a problem.

Like a dryer, or range.

The older ones have a 3 wire cord. The newer ones have a 4 wire cord. But all require a split-phase ground. (120v from L1 or L2 to ground)

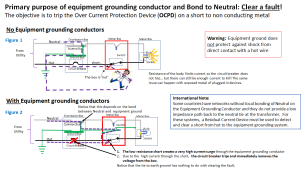

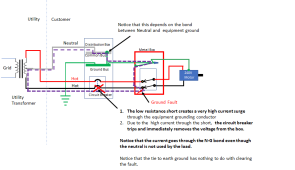

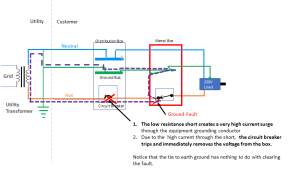

Another question- you said L1 and L2 are isolated from ground. Ie not bonded? I just want to make sure I understand this- if one of those makes contact with ground say via a metal case, the current will still travel back to the transformer via the neutral wire right?