Brucey

Solar Wizard

Some interesting stuff there.Search for Document #:493005-002 Battery Pack Design, Validation, and. Assembly Guide using A123 Systems.

Some interesting stuff there.Search for Document #:493005-002 Battery Pack Design, Validation, and. Assembly Guide using A123 Systems.

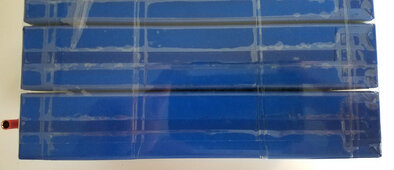

No. Just taped together using packing tape. I did not fully cycle them to limit cell bulging until I can properly compress them. Need to order some 1/2" alum plate for that.Did you have them clamped?

This seems relevant to my concern:Search for Document #:493005-002 Battery Pack Design, Validation, and. Assembly Guide using A123 Systems.

Not sure what that means to start at 7% thicker though.Over the course of the cell’s lifetime as it ages during regular service, its thickness will grow to be 3 – 5% greater than initial thickness.

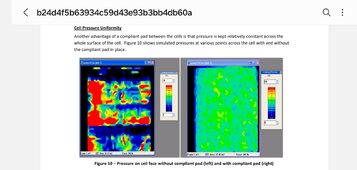

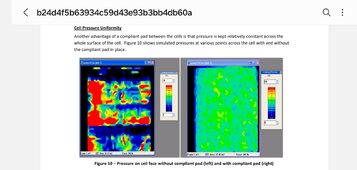

That's because you had them clamped since they were new. But clamping them without compliant material risks damaging them long term as they age.No bloating, no bulging. Still flat as ever.

But clamping them without compliant material risks damaging them long term as they age.

18650 will not replace it?I also bought 32 of these but one cell the negative terminal snapped off with very little force, super annoying, not sure how to fix it, maybe solder with that low temp solder paste? Will that work?

I have not asked, i dont want to have to take it out I already have it fully built into my XR-04 Enclosure, which I absolutely love BTW, for 250 shipped this thing is really well built, I have a 2nd one coming and will do pictures of it and the 2nd build, it's really nice and for the price unbeatable.18650 will not replace it?

contact them. it seems to be a known issue. happened to me and they replaced it quickly with almost no questions askedI have not asked, i dont want to have to take it out I already have it fully built into my XR-04 Enclosure, which I absolutely love BTW, for 250 shipped this thing is really well built, I have a 2nd one coming and will do pictures of it and the 2nd build, it's really nice and for the price unbeatable.

Wrong topicSo, I'm building my first LiFePO4 pack. 4S2P from new 105AH EVE cells, Overkillsolar BMS. Pretty standard stuff. Then I get to the whole compression topic...

I read the EVE data sheet, and I think we need to be a bit more pedantic about what it says, and more importantly what it doesn't say. The datasheet is only a spec for what comes out of the factory, and how to confirm / measure it (i.e. a QA document). The entire discussion in the datasheet regarding compression is under the section where they are specifying the battery cell dimensions. In other words, since the cells do swell with charging, in order to specify the product dimensions (the thing they are going after) they need to specify how much compression the cells are under. They spec'd 300 kgf for this test, describe the test jig, and under those conditions they show what the cell dimensions should be.

They did NOT specify that the cells should be operated at that compression (nor that they shouldn't be, to be clear). This is only a spec for the conditions to measure the dimensions of the cell.

An email exchange with the 18650 support team said that the cells should be used with compression, and pointed to the datasheet. That, in my pedantic mind, doesn't answer the question.

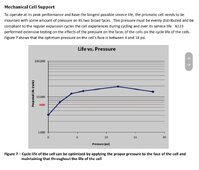

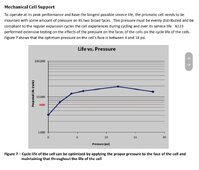

The only information I have seen about what compression should be applied is the graph that Brucey cited in post #441, but I don't believe that came from EVE.

Has anyone seen an actual "This is how you should mechanically construct a multi-cell battery with these cells." document from EVE?? (Or Envision for that matter, to stay on topic... I was going to use the 305's but they were out of stock.)

With the A123 graph, we can see that with zero compression lifecycle is 3000. With some pressure applied that shoots up to 6000 and then eventually nearly 20,000 cycles.So, I'm building my first LiFePO4 pack. 4S2P from new 105AH EVE cells, Overkillsolar BMS. Pretty standard stuff. Then I get to the whole compression topic...

I read the EVE data sheet, and I think we need to be a bit more pedantic about what it says, and more importantly what it doesn't say. The datasheet is only a spec for what comes out of the factory, and how to confirm / measure it (i.e. a QA document). The entire discussion in the datasheet regarding compression is under the section where they are specifying the battery cell dimensions. In other words, since the cells do swell with charging, in order to specify the product dimensions (the thing they are going after) they need to specify how much compression the cells are under. They spec'd 300 kgf for this test, describe the test jig, and under those conditions they show what the cell dimensions should be.

They did NOT specify that the cells should be operated at that compression (nor that they shouldn't be, to be clear). This is only a spec for the conditions to measure the dimensions of the cell.

An email exchange with the 18650 support team said that the cells should be used with compression, and pointed to the datasheet. That, in my pedantic mind, doesn't answer the question.

The only information I have seen about what compression should be applied is the graph that Brucey cited in post #441, but I don't believe that came from EVE.

Has anyone seen an actual "This is how you should mechanically construct a multi-cell battery with these cells." document from EVE?? (Or Envision for that matter, to stay on topic... I was going to use the 305's but they were out of stock.)

Wouldn't these age out around the same time as a 304ah wasting even more cycles, or do they age differently?With the A123 graph, we can see that with zero compression lifecycle is 3000. With some pressure applied that shoots up to 6000 and then eventually nearly 20,000 cycles.

The majority of diyers prob won't reach that lower 3000 cycle limit due to having larger battery banks etc and calendar aging, so even if there is no compression applied the lifetime results will be good. But with newer cells like the lf560k rated for 12,000 cycles etc it would seem wise to use a fixture and apply pressure for prismatic cells.