You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Are 48V chargers necessary if owning HYBRID LV6048?

- Thread starter buck4424

- Start date

MichaelK

Solar Wizard

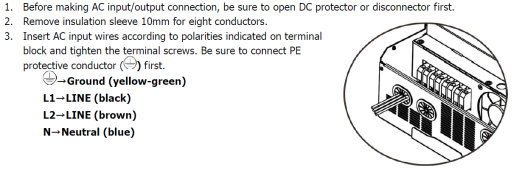

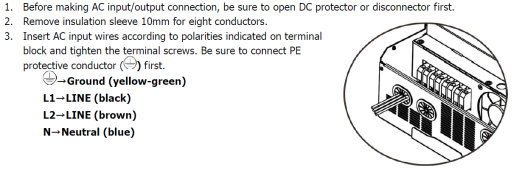

Your unit already has a built-in charging circuit, so there's really no reason to have an extra charger. Follow the instructions on page 6 of the manual to connect the ACin wiring. ACin can be either the grid, or split-phase 120/240VAC generator.

Please note though that some inverters can be fussy about the quality of power a generator is supplying. It looks at the voltage, and frequency of the power coming in and decides if the generator is "qualified" to supply power to the inverter. You may need to fiddle with the max charging rate to get the inverter to accept what's coming in.

Please note though that some inverters can be fussy about the quality of power a generator is supplying. It looks at the voltage, and frequency of the power coming in and decides if the generator is "qualified" to supply power to the inverter. You may need to fiddle with the max charging rate to get the inverter to accept what's coming in.

LazyDragon

New Member

- Joined

- Mar 18, 2022

- Messages

- 29

It depends on how your inverter is setup too. If you are using 120/240 split phase output, your generator input also has to be 120/240 split phase. This limits your choice of generators to larger units. I have an MPP5048; basically the same inverter as you. I use a 9kw open frame generator that can provide 120/240, which the inverter will use to drive the load and also charge batteries. It is also noisy, makes dirty power and is inefficient.

I wanted a way to use a small, quiet inverter generator to charge the batts, but they all supply 120V single phase. That means I needed a separate battery charger since the MPP5048 won't accept the 120VAC input.

I shopped around for 48V battery chargers, but the units that could provide any decent amps (30A at 48V) were pretty expensive and they didn't support my DIY batteries with a different operating range.

Finally I just bought a second hybrid inverter (growatt 3000) to use just for charging. It only cost a little more than a battery charger, and it also gives me additional solar inputs, better charging control and a redundant inverter in case my main unit had a problem.

These inexpensive hybrid units can be useful in many different ways. They can also be a pain in the ass, but that's another thread LOL.

I wanted a way to use a small, quiet inverter generator to charge the batts, but they all supply 120V single phase. That means I needed a separate battery charger since the MPP5048 won't accept the 120VAC input.

I shopped around for 48V battery chargers, but the units that could provide any decent amps (30A at 48V) were pretty expensive and they didn't support my DIY batteries with a different operating range.

Finally I just bought a second hybrid inverter (growatt 3000) to use just for charging. It only cost a little more than a battery charger, and it also gives me additional solar inputs, better charging control and a redundant inverter in case my main unit had a problem.

These inexpensive hybrid units can be useful in many different ways. They can also be a pain in the ass, but that's another thread LOL.

Thank you LazyDragon. I wonder why it gets noisy. I looked in the 48 v chargers and they were expensive and I was considering 25amp. I really appreciate your feedback. I'm going to purchase the 3000 growatt inverter. Which 3000 inverter did you purchase? I'm trying to save money but do not want to go anymore backwards, lol.

LazyDragon

New Member

- Joined

- Mar 18, 2022

- Messages

- 29

SPF 3000TL LVM-ES

It's pretty slick as a battery charger. The unit is powered off (power switch off), but it turns on automatically when it sees the utility power come up. The switch is off, so the inverters stay off. But it will see the batteries and start charging them. When the utility power turns off, the unit will delay about 60 seconds, then turn itself off.Like all the MPP style systems, it has it's quirks.

1) If the batt voltage is too low, the unit will start but it won't charge. Somewhere below 41.5V, I'm not sure where. Below 42.5V, it will charge, but it delays about 2 minutes first. Above 42.5V, it will start charging immediately.

2) This is the really quirky one. I had the charge source set to SOL+UTIL, where it will charge from either source. This leads to some strange behavior. As it charges the batt from Utility, when it reaches a round number like 44.0V or 45.0V, it tries to evaluate the solar source. It disconnects the utility charger to do this. That causes the generator load to suddenly drop from 2kw to 0, which makes the gen surge and struggle to recover.

The charger works by applying a higher voltage to the battery input. So if the batts are at 44.5V, the charger sets the bus to 44.9V to send power to the batts. Then as the batts charge up, the buss V changes to 45.0. This causes the SPF to check on the Solar input, so it disconnects the charger, the generator surges, the battery buss voltage drops to 44.5 and the cycle starts over again. Over and over.

As with most things on these units, tech support is typically not helpful.

The fact that this happened at different voltage levels (43.0, 44.0, 45.0) but always at the XX.0 level made me suspicious that it was in fact a logic issue with the inverter.

I changed the charge source to SOL (solar first). Of course there is no solar input. But with this setting, it turns off the messed up logic for checking the solar input. Set to SOL, the unit charges very smoothly from the utility input. Go figure...

The SPF has a max charge rate of 40A on utility. 2Kw. That matches up nicely with a small genverter. I use a westinghouse i4500DF that runs on propane and has remote start.

I'm living off grid. I have a champion generator and run on propane. Starting watts is 3950 and running is 3150. So if I understand correctly I will have to set my inverter to accept SOL + UTIL for it to work? Setting to SOL will not work? Thank you so much for your help and knowledge.

LazyDragon

New Member

- Joined

- Mar 18, 2022

- Messages

- 29

I don't see where you ever specified if your LV6048 is setup for 120/240 split phase output. I assume that is true since you are looking for a battery charger alternative to work with your Champion generator that puts out 120VAC.

You would need to set your battery charger SPF3000 to SOL, which does seem counterintuitive. It will work on SOL+UTIL, but it might have the odd behavior I mentioned. All the chinese hybrids have their own quirks. Maybe an MPP unit would work differently. You just have to experiment and see. Its part of the penalty for saving money on the unit itself.

Does your Champion generator have push-button electric start? If not, consider getting a westinghouse. It is such a handy feature to be able to start the gen without going outside. Check out SwitchBot for being able to remote-push the start button.

You would need to set your battery charger SPF3000 to SOL, which does seem counterintuitive. It will work on SOL+UTIL, but it might have the odd behavior I mentioned. All the chinese hybrids have their own quirks. Maybe an MPP unit would work differently. You just have to experiment and see. Its part of the penalty for saving money on the unit itself.

Does your Champion generator have push-button electric start? If not, consider getting a westinghouse. It is such a handy feature to be able to start the gen without going outside. Check out SwitchBot for being able to remote-push the start button.

Yes it is set of for 120/240 split phase. That makes sense setting up growatt to SOL. I'm not running yet but getting ready to. I'm in-between deciding to put in my camper or shed. How hot do the inverters get when on a load? Do they require venting from all directions excluding back side attached. My camper is only 18' is the reason I'm asking. I would love to put it all in my 10'x10' shed but would have to heat in the winter time. Sorry LazyDragon I forgot to post this yesterday.

LazyDragon

New Member

- Joined

- Mar 18, 2022

- Messages

- 29

The inverters don't get hot at all. If you're running it so hard for so long that heat becomes a problem, you're probably running out of battery soon anyway

They cool themselves with internal fans that spool up or down depending on the load (or solar input). When they crank up, they make quite a bit of noise. Something else to consider if you want to put it in your living space.

The inverters will operate at low temps. I assume you're concerned about the batteries? I'm in western WA, so my outside shed did ok with just some extra heat from the generator which I vented through the battery area to help warm them. Your climate might require much more. There are some threads on the boards about keeping batteries above freezing. Those might offer some help.

Another plus for the shed is that if something goes tits up and there is a fire, you want it away from your house.

With the inverter in a separate building, you want a convenient way to monitor it. Don't bother with the wifi devices for any of the MPP/Growatt type inverters. The software sucks. Check out solar-assistant.io instead.

They cool themselves with internal fans that spool up or down depending on the load (or solar input). When they crank up, they make quite a bit of noise. Something else to consider if you want to put it in your living space.

The inverters will operate at low temps. I assume you're concerned about the batteries? I'm in western WA, so my outside shed did ok with just some extra heat from the generator which I vented through the battery area to help warm them. Your climate might require much more. There are some threads on the boards about keeping batteries above freezing. Those might offer some help.

Another plus for the shed is that if something goes tits up and there is a fire, you want it away from your house.

With the inverter in a separate building, you want a convenient way to monitor it. Don't bother with the wifi devices for any of the MPP/Growatt type inverters. The software sucks. Check out solar-assistant.io instead.

offgriddave

Solar Enthusiast

- Joined

- Feb 14, 2020

- Messages

- 225

I'm living off grid. I have a champion generator and run on propane. Starting watts is 3950 and running is 3150. So if I understand correctly I will have to set my inverter to accept SOL + UTIL for it to work? Setting to SOL will not work? Thank you so much for your help and knowledge.

your all in one inverter might not like the power from the champion generator and reject it

I know mine (WEN 3500 propane) won't work with LV5048, it rejected it. Although there are some tricks pointed out here I never tried them.

LazyDragon

New Member

- Joined

- Mar 18, 2022

- Messages

- 29

If the LV5048 is providing 120/240 split phase, it definitely won't like the 120V from a smaller generator.

I also had to do some tuning on my 9kw 120/240 generator. It was producing power at 59Hz. The LV5048 didnt like that. I had to bump up the frequency to 60Hz using a manual adjustment on the generator. That's another reason I wanted to change to a smaller inverter generator. Cleaner power output from the generator. Better for the inverter, better for devices in the house.

I also had to do some tuning on my 9kw 120/240 generator. It was producing power at 59Hz. The LV5048 didnt like that. I had to bump up the frequency to 60Hz using a manual adjustment on the generator. That's another reason I wanted to change to a smaller inverter generator. Cleaner power output from the generator. Better for the inverter, better for devices in the house.

offgriddave

Solar Enthusiast

- Joined

- Feb 14, 2020

- Messages

- 225

The best thing to happen would be a small inverter generator with remote start 2 wire (?) that ran on propane for under $700.

I think from memory the only one I could find was a Westinghouse but it did not have remote start 2 wire.

Edit: and 240/120v.

I think from memory the only one I could find was a Westinghouse but it did not have remote start 2 wire.

Edit: and 240/120v.

LazyDragon

New Member

- Joined

- Mar 18, 2022

- Messages

- 29

"small" and "120/240" never happen together. Anything that puts out 240 split phase is always 7kw or bigger and rarely an inverter generator.

I use westinghouse for both my 240 split 9kw generator, and 120V 3kw inverter generator. They were the only ones I could find that had all my required features. Both are dual fuel which I run on propane. Most importantly, they are true push-button start with an electric choke. They support "smart switch" so you could somehow wire them up for remote start.

I got around that with a remote control push-button device called a SwitchBot. It physically pushes the start button on the gen. Handy little device for $20. I then started using some other switchbot stuff. I *could* set my system to automatically push the button when the batts get below a certain threshold, but I don't trust it 100% to run when I'm away. Mainly the generator startup.

When you push the button, the 3kw genverter will attempt to start the engine two times, then it gives up.

There have been a few times where the engine *almost* started. It turned over once, which was enough to make the starter think everything was ok. But it wasn't. The engine didn't start. Not a big deal on its own. But in an automated environment, it can lead to confusion. I don't have the time to build in extra redundancy or monitoring, so I don't trust it to be fully automated *and* unattended.

I use westinghouse for both my 240 split 9kw generator, and 120V 3kw inverter generator. They were the only ones I could find that had all my required features. Both are dual fuel which I run on propane. Most importantly, they are true push-button start with an electric choke. They support "smart switch" so you could somehow wire them up for remote start.

I got around that with a remote control push-button device called a SwitchBot. It physically pushes the start button on the gen. Handy little device for $20. I then started using some other switchbot stuff. I *could* set my system to automatically push the button when the batts get below a certain threshold, but I don't trust it 100% to run when I'm away. Mainly the generator startup.

When you push the button, the 3kw genverter will attempt to start the engine two times, then it gives up.

There have been a few times where the engine *almost* started. It turned over once, which was enough to make the starter think everything was ok. But it wasn't. The engine didn't start. Not a big deal on its own. But in an automated environment, it can lead to confusion. I don't have the time to build in extra redundancy or monitoring, so I don't trust it to be fully automated *and* unattended.

offgriddave

Solar Enthusiast

- Joined

- Feb 14, 2020

- Messages

- 225

This guy :

dcautogen.com

dcautogen.com

But I am unable to justify a 48v only gen. I would rather have the dual use as a failback

@LazyDragon How can we make autostart a reality? Lets do this.

V5 AutoGen 48v DC Generator | Smartest 48v DC Generator

V5 AutoGen Automatic Start 48v DC Generator. Designed to automatically startup and charge low battery banks. Accessible over wifi through our ...

But I am unable to justify a 48v only gen. I would rather have the dual use as a failback

@LazyDragon How can we make autostart a reality? Lets do this.

LazyDragon,

I'm in southern colorado at 7300 feet. I gets pretty cold here in the winter as my property is limited with sun due to mountains blocking the sun at this time of year. Your probably aware of this website sunCalc.org. It's a way of studying the sun. My only concern with using the shed is the length of the wire needed to get to my camper. How far away would you place the shed from the camper? The longer the wire your power will diminish won't it? What gauge of wire would you use from shed to camper? Appreciate your support as always. Have a good one.

I'm in southern colorado at 7300 feet. I gets pretty cold here in the winter as my property is limited with sun due to mountains blocking the sun at this time of year. Your probably aware of this website sunCalc.org. It's a way of studying the sun. My only concern with using the shed is the length of the wire needed to get to my camper. How far away would you place the shed from the camper? The longer the wire your power will diminish won't it? What gauge of wire would you use from shed to camper? Appreciate your support as always. Have a good one.

MichaelK

Solar Wizard

This is where the features of the modern MPPT controller shine. In the olden days, when only the PWM controller was available, voltage drop was a very serious issue, and drastically limited panel distance.My only concern with using the shed is the length of the wire needed to get to my camper. How far away would you place the shed from the camper? The longer the wire your power will diminish won't it? What gauge of wire would you use from shed to camper? Appreciate your support as always. Have a good one.

Today's MPPT controllers act as a transformer, taking raw high panel voltage, and transforming it down to the voltage the battery wants. The extra volts gets converted into extra amps, so you get more out of a panel. So, panels can be wired in series to raise the string voltage to cross distances of hundreds of feet.

Details here are important though. You need to know your voltage limits of your equipment, and respect those, especially because the Voc goes up as the temperature goes down. If your unit has a Voc limit of 145V, then you need to determine what the maximal Voc will be on the historically coldest day of the year, which is likely to be around -40 or so? You can use this string calculator from Midnight to determine what your string limit would be. I'd guestimate though that you should be able to wire three grid-tie panels in series for 90V and be OK.

MidNite Solar - KID Sizing Tool.

MidNite Solar is the industry leader and manufacture of quality Renewable Energy System electrical components and E-Panels.

www.midnitesolar.com

LazyDragon,

I looked up Voc in my manual. I'm going to paste it here as I want to make sure I fully understand. VOC=Volts on Charge VDC=Volts of direct current. What is the difference or are they the same? Here is my midnite solar specs: I don't think I did it right. Definite beginner, thanks for your patience.

MIDNITE SOLAR'S KID SIZING TOOL

PV Connection

CAUTION: Before connecting to PV modules, please install separately a DC circuit breaker between inverter

and PV modules.

WARNING! All wiring must be performed by a qualified personnel.

WARNING! It's very important for system safety and efficient operation to use appropriate cable for PV

module connection. To reduce risk of injury, please use the recommended cable size as below.

NOTICE! When only one MPPT is used, please use MPPT1 first.

Model Typical Amperage Cable Size Torque

HYBRID LV 6048 80A 8 AWG 1.4~1.6 Nm

PV Module Selection:

When selecting proper PV modules, please be sure to consider the parameters below:

1. Open circuit Voltage (Voc) of PV modules can’t exceed the maximum voltage of the PV array open circuit of

the inverter.

2. Open circuit Voltage (Voc) of PV modules should be higher than the minimum voltage of the battery.

Please follow the steps below to implement PV module connection:

1. Remove insulation sleeve 10 mm from positive and negative conductors.

2. Check the correct polarity of connected cable from PV modules and PV input

connectors. Then, connect positive pole (+) of connection cable to positive

pole (+) of PV input connector. Connect negative pole (-) of connection

cable to negative pole (-) of PV input connector.

3. Make sure the wires are securely connected.

Solar Charging Mode

Solar Charger Type MPPT

Number of MPPT 2

Max. PV Array Open Circuit Voltage 145Vdc

PV Array MPPT Voltage Range 60~115Vdc

Min. battery voltage for PV charge 34Vdc

I looked up Voc in my manual. I'm going to paste it here as I want to make sure I fully understand. VOC=Volts on Charge VDC=Volts of direct current. What is the difference or are they the same? Here is my midnite solar specs: I don't think I did it right. Definite beginner, thanks for your patience.

MIDNITE SOLAR'S KID SIZING TOOL

| PRINT RESULTS

|

PV Connection

CAUTION: Before connecting to PV modules, please install separately a DC circuit breaker between inverter

and PV modules.

WARNING! All wiring must be performed by a qualified personnel.

WARNING! It's very important for system safety and efficient operation to use appropriate cable for PV

module connection. To reduce risk of injury, please use the recommended cable size as below.

NOTICE! When only one MPPT is used, please use MPPT1 first.

Model Typical Amperage Cable Size Torque

HYBRID LV 6048 80A 8 AWG 1.4~1.6 Nm

PV Module Selection:

When selecting proper PV modules, please be sure to consider the parameters below:

1. Open circuit Voltage (Voc) of PV modules can’t exceed the maximum voltage of the PV array open circuit of

the inverter.

2. Open circuit Voltage (Voc) of PV modules should be higher than the minimum voltage of the battery.

Please follow the steps below to implement PV module connection:

1. Remove insulation sleeve 10 mm from positive and negative conductors.

2. Check the correct polarity of connected cable from PV modules and PV input

connectors. Then, connect positive pole (+) of connection cable to positive

pole (+) of PV input connector. Connect negative pole (-) of connection

cable to negative pole (-) of PV input connector.

3. Make sure the wires are securely connected.

Solar Charging Mode

Solar Charger Type MPPT

Number of MPPT 2

Max. PV Array Open Circuit Voltage 145Vdc

PV Array MPPT Voltage Range 60~115Vdc

Min. battery voltage for PV charge 34Vdc

Similar threads

- Replies

- 1

- Views

- 178