I've read, in this forum, that bus bars with equal length cables is the preferred method for wiring batteries in series. The submitted argument was that electricity seeks the shortest path and wiring all batteries to a bus bar reduces path length, allowing all batteries to equally participate in draw-down and recharge cycles.

The argument is that the batteries are measured in duty cycles and a battery at an endpoint will endure more cycles than the ones connected to it. Furthermore, once the endpoints receive a reach their recharge point, they are further taxed by recharging the batteries 'in the middle', consuming additional cycles to achieve balance.

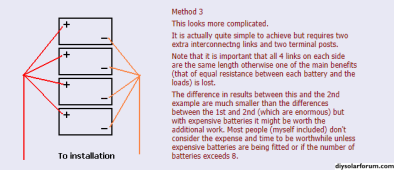

Some on other forums ( e.g. youtube) advocate wiring batteries in series by connecting the positive and negative terminals of the batteries to each other and separating the endpoints, with one battery at the head of the positive, another the head of the negative power distribution.

Why does this contradiction exist? Is it a matter of economics (cost vs. benefit) or is it just a shortcut? A lot of youtubers build 'pretty installations. My question is what is the correct approach to wiring batteries for consumption and recharge.

Thanks for your time.

The argument is that the batteries are measured in duty cycles and a battery at an endpoint will endure more cycles than the ones connected to it. Furthermore, once the endpoints receive a reach their recharge point, they are further taxed by recharging the batteries 'in the middle', consuming additional cycles to achieve balance.

Some on other forums ( e.g. youtube) advocate wiring batteries in series by connecting the positive and negative terminals of the batteries to each other and separating the endpoints, with one battery at the head of the positive, another the head of the negative power distribution.

Why does this contradiction exist? Is it a matter of economics (cost vs. benefit) or is it just a shortcut? A lot of youtubers build 'pretty installations. My question is what is the correct approach to wiring batteries for consumption and recharge.

Thanks for your time.