Hedges

I See Electromagnetic Fields!

- Joined

- Mar 28, 2020

- Messages

- 20,690

Howdy UE, welcome to the party.

That will work great on my vehicle batteries which are Lead-Acid but if I ever need to do that to a LiFePO4, you will see a grown man cry.

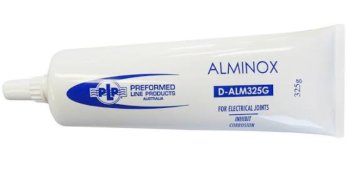

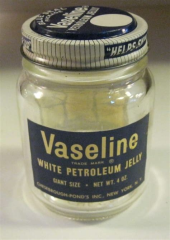

Hey mate, just saw you concern about cleaning the terminals and connection well I know the approach which I found pretty good in some my clients case. Battery terminals can be cleaned with a mixture of baking soda and distilled water using a battery terminal cleaner brush. Afterward rinse the terminals with water, ensure that all connections are tight and coat the metal components with a commercial sealant or a high temperature grease. This is one of the approach which may help you or if you found out the better way I am open for suggestions.

p.s.: you won't last long here promoting your business. And you're showing your ignorance presenting inane suggestions (given the topic at hand.)

If you want to learn some new things from DIY and experienced people, hang around and read the threads. But the owner of the forum recently purged membership of almost all people from companies, except those who were actually helping.