brandnewb

Going for serious. starting as newb

I just was trying to be polite and now you attecked me on it.. uncool

Some interesting ideas, but not how it works. Torque is a rotational force. It doesn't directly compared to the force holding 2 magnets together.

Also, its the interaction between the magnets and the coil. The number of turns and size of the wire are critical.

Foot pounds is a rotational force. You can't estimate it as you describe.

700 ft lbs is more torque than the 400hp engine in my car produces. It is an immense amount of torque.

70 ft lbs will exceed the structural strength of the frame using the construction being applied.

.

I am so pissed off by the way this happy thread turned dark just now.

Why people why?

Because I've encountered dozens and dozens of people convinced they have the best idea in the world, and due to at least a fundamental lack of understanding of ONE aspect, their idea can be demonstrated to be completely wrong.

I am failing misserably thinking of a way to do just that. Reason being is that if I hold my scale too close it will get messed up by the magnetic fields.Hold a pair of magnets spaced apart as far as the air (or copper, or plastic or OSB) gap they will see in this alternator.

Measure the force between them.

ugg, this will mean another 2 or 3 days added to this project ;( @Hedges is it at all okay if we use this 12kg value of magnetic puling force for the time being?

I am failing misserably thinking of a way to do just that. Reason being is that if I hold my scale too close it will get messed up by the magnetic fields.

no, i think I have an idea. how about I putt 2 sets of those magnets on a piece of wood so far appart that the magnetic field cant mess up the scale readings and then measure the attractive streangth. we then need to divide my some measure . I am thinking divide by 2

NOOOOOOOOOOOOOOOOOOOOOOOO. I have but 1 child @ 3 year old and already TOOOOOOOO much. never again if I can avoid it

That is easily done. I have huge pieces of steel around here somewhere in my garage easily heavier than 12kgOr, put a piece of steel > 12kg on scale. Lower magnet towards it, reducing weight on scale. To avoid pinching fingers, wrap a piece of cloth around magnet and hang that over the steel.

I meant to say 1 is already too much. I'd like to prevent having moreNOOOOOOOOOOOOOOOOOOOOOOOO. I have but 1 child @ 3 year old and already TOOOOOOOO much. never again if I can avoid it

this one is even more brilliant!!Something like that. Put a block of wood and one magnet on top of the scale. Bring second magnet close to same pole so it pushes away, measure force vs. distance.

yes sir, as soon as I am done with the followingTo confirm this has anything to do with anything, you could also wind a single coil of wire (representing 1/96 of stator), run DC current through it, and move a 2-magnet mockup of your armature past it. Measure the force on coil. Then try iron core in coil and iron pole piece joining backs of the magnets. (or maybe 4 magnet mockup, pole pieces for each pair to be more like two rotors.)

Power needs speed, distance over time. But use this mockup to measure stall torque (force) by applying DC current.

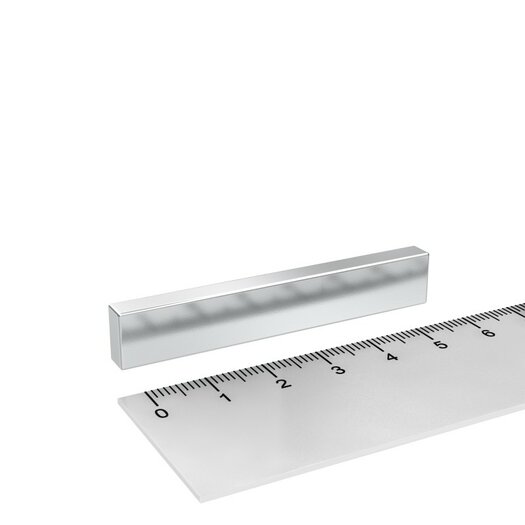

I am willing to dig deeper constructing some kind of setup to make for precise and consistent measurements possibleView attachment 75014

at +-25mm distance the opposing force was +- 241g(gram)

at +-15mm distance the opposing force was > 550g

I'll admit that this test was mostly manual and thus giving my trademark earthshaker hands not reliable at all.

Any closer and I would repell the whole setup over,.

I meant to say that these magnets when close are soo strong they can topple this setupAny closer and I would repell the whole setup over,.