KevinC_63559

New Member

If I'm following design rules, I believe I need to factor in record weather to come up with an appropriate correction factor correct?

e.g. Although our average minimum temperature is around -9C, its not uncommon to have a week or so at -20C. Looking at record temps, we have gotten down as low as -35C. This year, for example, was REALLY cold (at least for us) with about 10 days around -32C.

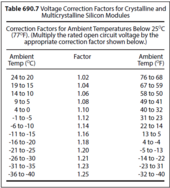

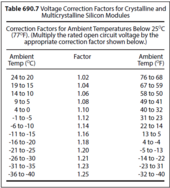

Found this table in some old Midnight documentation I had stored:

Feels like I should use 1.25 to be safe, given the unknown variation of upcoming climate change. Does that make sense?

Of course, I'll do the math based on whatever panels I eventually select in conjunction with whatever MPPT charge controller I select maximum's VOC.

Its just that planning for the worst known conditions, when all one has is historical data, feels dicey. It would be painful to blow up an MPPT (and potentially burn up the building its in), just because we had a random really cold sunny morning.

Does anyone other than Midnight offer anything similar to their HyperVOC (which will shutdown their MPPT units if the maximum voltage is exceed, with a non-operating range boosted by that plus the battery voltage (e.g. Using one of their 250V chargers with a 48V battery allows for up to 298V before the unit is damaged)? Seems like that would be quite handy for extreme weather a few days a year.

For example, if I used a Victron 450V/100 Smart solar with (8) 50VoC panels in series I'd be fine most of the time, (down to around -5C) but would fry the system on that cold day (400X1.25=500 >> 450). To be somewhat safe I'd have to limit the system to (7) panels (427.5Voc).

Am I doing that math right?

e.g. Although our average minimum temperature is around -9C, its not uncommon to have a week or so at -20C. Looking at record temps, we have gotten down as low as -35C. This year, for example, was REALLY cold (at least for us) with about 10 days around -32C.

Found this table in some old Midnight documentation I had stored:

Feels like I should use 1.25 to be safe, given the unknown variation of upcoming climate change. Does that make sense?

Of course, I'll do the math based on whatever panels I eventually select in conjunction with whatever MPPT charge controller I select maximum's VOC.

Its just that planning for the worst known conditions, when all one has is historical data, feels dicey. It would be painful to blow up an MPPT (and potentially burn up the building its in), just because we had a random really cold sunny morning.

Does anyone other than Midnight offer anything similar to their HyperVOC (which will shutdown their MPPT units if the maximum voltage is exceed, with a non-operating range boosted by that plus the battery voltage (e.g. Using one of their 250V chargers with a 48V battery allows for up to 298V before the unit is damaged)? Seems like that would be quite handy for extreme weather a few days a year.

For example, if I used a Victron 450V/100 Smart solar with (8) 50VoC panels in series I'd be fine most of the time, (down to around -5C) but would fry the system on that cold day (400X1.25=500 >> 450). To be somewhat safe I'd have to limit the system to (7) panels (427.5Voc).

Am I doing that math right?