Being you are installing on an RV, solar watts are EXTREMELY precious!

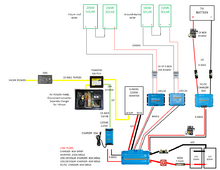

Make sure you go with a high quality mppt solar charge controller (SCC) - since your drawing shows a Victron Smartshunt and would HIGHLY recommend using a Victron Smart mppt charge controller. Having both the Victron Smartshunt (or BMV712) and the Victron mppt SCC, lets you setup a Bluetooth network between the two. The shunt will pass voltage, current, and temperature (if you install an optional temp sensor), the mppt then uses that data to adjust the charging to compensate for wiring voltage losses, useage of power, and if the battery is too cold - doesn’t charge until the battery is warmer.

With the SCC being a mppt, it doesn’t matter if the panels are “12v”, “24v, “36v”, or close to “50v”, it will convert the extra voltage to amps to charge the battery.

For RV’s because we often park in areas that have changing shade, we use more parallel setups than the houses which use more series setups. In one array I have 4 200w panels, I have them setup as 2s2p, two panels in the front area in series, two in the back in series, then those connected into parallel and going into the Victron 100/50 mppt. (Those panels were the “12v” panels- the voltage is about 20v - so I have about 40v going into the mppt - works great!).

For panels, a good rule of thumb (if it is convenient) is to have about double the battery voltage going into the mppt, then go parallel for more panels. But if that is not convenient don’t worry about it. That just keeps voltage high so the mppt starts early in the morning, and then has more in parallel to compensate for the changing shade issues. So if you were to buy 24v or 36v panels, I would connect them in parallel.

Installing panels is a Tetris game, trying to get the most WATTS, into the small space with vents,skylights, air conditioners, etc.

Good Luck