Hi all,

I’ve been browsing for a few days and have just purchased some GEB21700 battery’s in small quantity for testing.

Firstly I ask of you if there is any decent charge/discharge cycle testers that I can purchase for a reasonable price. To be able to check capacities of cells.

I’ve considered Lifepo4 as a potential battery source, however the weight difference will be close to 1T. For around 550-600kwh

I’ve decided at the moment to purchase some 21700 batteries in small quantitys and test the capacities.

Build is an Austral Tour-Master and will most likely see an Axial Radial Flux motor from Emerax producing 400kw peak and 500nm torque mated to the original gearbox.

Solar will be a fold out system comprising of triple the roof space and coming close to 20kwh on the rooftop.

These will most end up as SunMan flexible lightweight cells.

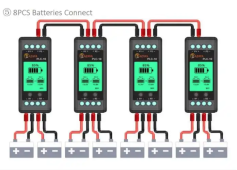

Bms will be broken into small 12v Modules. This will let the bms system stay lightweight. Each 12v system will have an active balancer attached in conjunction with a 12v bms.

Being 12v they can then be balanced with off the shelf 12v balancers, one to the other simply. If one bms drops it will through sone fancy electronic relay wizardry, drop the contactor and protect the HV battery pack. (Custom PCB) I will design.

This being an easy way of building a full battery management system.

I will most likely build the packs in smaller 12v cells and capacity test/balance and match them to lessen cell drifting. Also making failures fare more easy to access and repair.

She is old but perfect donar vehicle, the money saved on buying a bus that needs work allows a roof rebuild, probably half the cost of the battery.

I’ve been browsing for a few days and have just purchased some GEB21700 battery’s in small quantity for testing.

Firstly I ask of you if there is any decent charge/discharge cycle testers that I can purchase for a reasonable price. To be able to check capacities of cells.

I’ve considered Lifepo4 as a potential battery source, however the weight difference will be close to 1T. For around 550-600kwh

I’ve decided at the moment to purchase some 21700 batteries in small quantitys and test the capacities.

Build is an Austral Tour-Master and will most likely see an Axial Radial Flux motor from Emerax producing 400kw peak and 500nm torque mated to the original gearbox.

Solar will be a fold out system comprising of triple the roof space and coming close to 20kwh on the rooftop.

These will most end up as SunMan flexible lightweight cells.

Bms will be broken into small 12v Modules. This will let the bms system stay lightweight. Each 12v system will have an active balancer attached in conjunction with a 12v bms.

Being 12v they can then be balanced with off the shelf 12v balancers, one to the other simply. If one bms drops it will through sone fancy electronic relay wizardry, drop the contactor and protect the HV battery pack. (Custom PCB) I will design.

This being an easy way of building a full battery management system.

I will most likely build the packs in smaller 12v cells and capacity test/balance and match them to lessen cell drifting. Also making failures fare more easy to access and repair.

She is old but perfect donar vehicle, the money saved on buying a bus that needs work allows a roof rebuild, probably half the cost of the battery.