Dadoftheturkeykids

New Member

Hi all, this is my first post. I started my solar project last year in hopes to slowly break away from my reliance on the grid. They have ripped me off one too many times, and have never made right with me on their own errors. I just had to cough up money to pay for insanely high charges that came out of nowhere, either through their own shoddy line work that they mysteriously have no record of employing a crew to do in my backyard, or merging an account (outstanding balance) with the same address and name on the account I pay every month. I am sick of being tied to their schemes, but before now I had believed it would be the only way to restore my power is if I payed their inaccurate and insanely high balance.

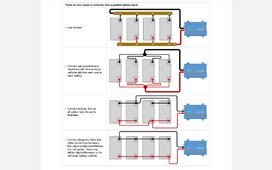

So here is my current battery setup

4- 12v 200ah plus wired in parallel

4- 40amp mppt charge controllers

1- 12v 3000 watt inverter

1- 6 circuit manual transfer switch

2- 614wh portable power stations

I use the power stations for the kids entertainment purposes (charging devices, and gaming and such) charged up by

2-100 watt panels in parallel.

I tried to wire my battery up in 2s2p and bought a 24v inverter, but I had really bad unstable output with that inverter, so back to 12v I went.

I have 4-100 watt panels in parallel going to one charge controller and 6-100 watt panels going to another charge controller. My other 2 are not being used yet.

With this setup I can run my fridge and kitchen appliances, along with my entertainment center in the living room pretty steadily and stay around 65% capacity, until I get 4-5 days with no sun. Currently my panels are covered in snow on my roof.

Those were the initial panels I had bought with my new hobby, but I just scored

8-545watt bifacial panels that I will be replacing all 12-100 watt panels with when the weather permits me to work up there on the roof. I will most likely sell those panels and portable power stations because I am really digging the transfer switch... I know I am a rookie in this solar game, and aware that I may not have everything correct, buy I am learning as I go. Constructive criticism appreciated, but also I am kinda stuck in some of my ways as I had already invested a bit into my current system.

I am adding this to the forum not only to contribute to the forum, but also for my own means of being able to ask questions in the future pertaining to my system.

Yall really are a great community here and I've learned a ton from everybody's perspective. Thanks for looking and thanks for the feedback!

I will have questions in the near future ?

But photo drop for now?

So here is my current battery setup

4- 12v 200ah plus wired in parallel

4- 40amp mppt charge controllers

1- 12v 3000 watt inverter

1- 6 circuit manual transfer switch

2- 614wh portable power stations

I use the power stations for the kids entertainment purposes (charging devices, and gaming and such) charged up by

2-100 watt panels in parallel.

I tried to wire my battery up in 2s2p and bought a 24v inverter, but I had really bad unstable output with that inverter, so back to 12v I went.

I have 4-100 watt panels in parallel going to one charge controller and 6-100 watt panels going to another charge controller. My other 2 are not being used yet.

With this setup I can run my fridge and kitchen appliances, along with my entertainment center in the living room pretty steadily and stay around 65% capacity, until I get 4-5 days with no sun. Currently my panels are covered in snow on my roof.

Those were the initial panels I had bought with my new hobby, but I just scored

8-545watt bifacial panels that I will be replacing all 12-100 watt panels with when the weather permits me to work up there on the roof. I will most likely sell those panels and portable power stations because I am really digging the transfer switch... I know I am a rookie in this solar game, and aware that I may not have everything correct, buy I am learning as I go. Constructive criticism appreciated, but also I am kinda stuck in some of my ways as I had already invested a bit into my current system.

I am adding this to the forum not only to contribute to the forum, but also for my own means of being able to ask questions in the future pertaining to my system.

Yall really are a great community here and I've learned a ton from everybody's perspective. Thanks for looking and thanks for the feedback!

I will have questions in the near future ?

But photo drop for now?