DanielWNC

New Member

Hi everyone!

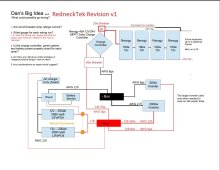

I need a mid size 500watt or so solar power in the short term, but I want to have the ability to scale up. So my plan is to overbuy some components, and leave the rest of the system viable for increasing substantially.

Having never done this before, I have spent a fair amount of time putting a plan together, and I would like you to review what I came up with as the eventual setup. I don't know if the components are "right-sized" to match each other, or if the (especially) wiring guages are correct, and a few other questions are on the plan itself.

If this is not the correct forum for this, please point me in the right direction.

Thanks in advance, I am so glad I found this discussion board!

Dan

I need a mid size 500watt or so solar power in the short term, but I want to have the ability to scale up. So my plan is to overbuy some components, and leave the rest of the system viable for increasing substantially.

Having never done this before, I have spent a fair amount of time putting a plan together, and I would like you to review what I came up with as the eventual setup. I don't know if the components are "right-sized" to match each other, or if the (especially) wiring guages are correct, and a few other questions are on the plan itself.

If this is not the correct forum for this, please point me in the right direction.

Thanks in advance, I am so glad I found this discussion board!

Dan