When you do skip wiring between panels, easier to mix things up.

Check voltage and polarity before making final connection to inverter or SCC. (be careful not to touch exposed DMM test leads when one is plugged into MC4 connector.) Also before paralleling the two strings, or plugging into anything where you can't see the other end. My meter typically reads Voc for a moment, decaying to zero as capacitance of open-circuit wire charges up. If not, current is going to flow when connected.

I have done similar wiring to minimize the extension PV wires needed.

Very important points, yes! Thanks. 100V is not for the faint-hearted, I've seen in videos that much lower voltage can kill you.

What I thought is, once I have all necessary items (missing still):

- just before darkness, connecting P1 to P4 in-series, and P5 to P8 in-series

- because of low light though, you cannot check now if voltage increased as expected, and if amperage is okay still

(next day then)

- and then connecting series-1 to series-2 in-parallel. It is here where I will increase wire size from AWG 14 to AWG 10 leading the wire down the house, into the basement, and back up the small bit to where the utility box is awaiting the roof panel power.

- Again, from where I combine both 100V 7.5A in-series strings, in-parallel to 100V 15A, I will use the thicker wiring through to the end, the Charge Controller (CC).

- Since it's "dark" by then, I assume it should be safe to make the connections. And any measurement in "darkness" wouldn't yield much above 0 anyway, is my thinking. Measurement would have to be next day, by checking of the CC puts anything out? If not, then comes the "fun" part: measuring in full sun

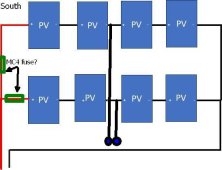

As promised, here a photo of the roof panel arrangement. Not as big as Tim's, be aware:

By the way, the low winter sun is the reason why I spread out the panels to this exact distance, it's all measured based on known sun's altitudes.

The particular constellation (I like the word here

) gave me rise to consider if the in-series strings should be comprising different panels, than what I understood FilterGuy suggested:

Anyway,

here FIY, if you are interested? This is how I've been angling all panels for the past 10ys, the rear wall panels use the same easy mechanism. On the roof, obviously, I will only make

one change between low winter sun, and high summer sun:

Given it's now about

roof wiring (strong sun here in summer!), I am still contemplating how I pin down the wiring:

- if you pin wiring straight onto the metal roof, it heats up needlessly (the roof is so hot in summer, I cannot step up! My wiring is silicone 200C though, so, it won't burn through from this). But still, you don't want to heat up your wiring

from the outside even. No.

- but if you don't pin down the wiring, you end up with loose wiring bouncing around (and at times touching the hot roof nonetheless!).

So, yeah, this is sth I am still contemplating what I would like most...

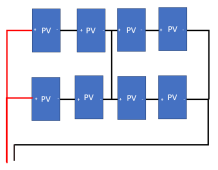

Then maybe something like this for 4S. Do this twice and connect the 2 strings in parallel anywhere that is convenient.

View attachment 183936

Yes exactly! Though I think it's what FilterGuy meant as well?