Three SanTan 250 watt panels in series, so around 100V and 6 to 8 amps.

As for what went wrong.

It wasn't abrasion, as the connector was cable tied under the panels to keep the sun off as our climate eats plastic.

Looking at the actual MC4 connector you go from 10AWG copper wire to a very thin steel, possibly tin plated, crimp connector inside the MC4.

Low resistance (copper) to a not so low resistance, friction fit of 2 circular steel parts, which may not be concentric leading to contact in only a few areas, then back to copper.

Lots of possible areas of high resistance, hence heating.

I've ordered these.

Polyolefin heat shrink butt connectors improved pullout strength, provides seal, strain relief, cable check, and insulation. Solder and seal and with advanced waterproof function. White Heat Shrink Connectors: Suits cable/ wire sizes AWG 26-24 / 0.25-0.34mm2.

www.ebay.com

And these.

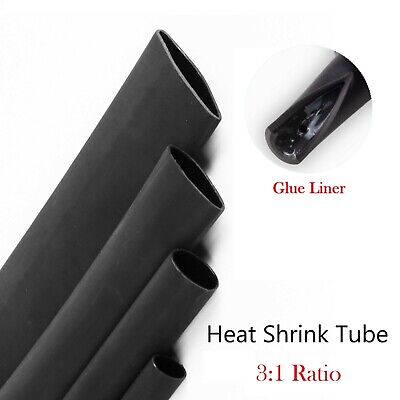

Dielectric strength: >15kV/mm. This is a waterproof shrink tubing with the internal adhesive layer. When cooled down, it forms a rigid seal. Therefore, 3:1 shrink ratio tubing can be used in significantly more applications compared to 2:1 shrink ratio tubing.

www.ebay.com

Just waiting for them to arrive and the battery bank to recharge.