Frank in Thailand

making mistakes so you don't have to...

I just ordered 16 x 152Ah "A-Grade" cells from Alibaba, for just $43 per cell. (+ connector / bus bar)

Door to door transport, all tax, customs clearance and handling paid $ 12 per cell. (and we live in so-called "remote area")

886 USD for 16X 3.2V 152Ah.

51.2x152= 7.782,4 Watts.

that is per watt $ 0,11385

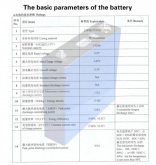

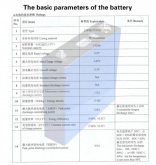

The specification sheet was made in august 2018. (see next post).

This could be that the cells are made in august 2018, but are never used.

It also can be that the cells are newer... I won't know till I receive them!

Link to product page: 3.2V 152Ah LiFePO4 lithium batteries for $43 !!

-- Sold out -- -- Sold out -- -- Sold out --

Hard to keep up with those guys, new stock, priced even little better $ 42

Link to new offer from this seller: 120Ah for $37.50, 280Ah for $73.80

some pictures of the product:

I can't find a way to upload the PDF, the 8 pages as jpeg go in next post.

I also ordered the $72 BMS Will showed in one of his videos.

The $72 BMS (temporary out of stock??)

16 string, 320A ...

I'm sure it will be fine for my solar system (But I won't try to get 320A!!)

(But I won't try to get 320A!!)

Door to door transport, all tax, customs clearance and handling paid $ 12 per cell. (and we live in so-called "remote area")

886 USD for 16X 3.2V 152Ah.

51.2x152= 7.782,4 Watts.

that is per watt $ 0,11385

The specification sheet was made in august 2018. (see next post).

This could be that the cells are made in august 2018, but are never used.

It also can be that the cells are newer... I won't know till I receive them!

Link to product page: 3.2V 152Ah LiFePO4 lithium batteries for $43 !!

Hard to keep up with those guys, new stock, priced even little better $ 42

Link to new offer from this seller: 120Ah for $37.50, 280Ah for $73.80

some pictures of the product:

I can't find a way to upload the PDF, the 8 pages as jpeg go in next post.

I also ordered the $72 BMS Will showed in one of his videos.

The $72 BMS (temporary out of stock??)

16 string, 320A ...

I'm sure it will be fine for my solar system

Last edited: