GridWorks Green Solar

Solar Innovator

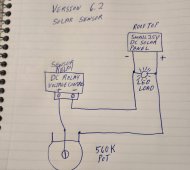

Several different ways to use and configure the project system.

Not recommended by this projects 200 max voltage rule, but have heard back from the UK several 220Volt AC 50 Hz systems have been built using the same power board and 40N65 MOSFETs.

These power boards have been on the market for at least 10 years for inverter repair and upgrades to pure sine power.

The project tamed the strong bias to earth ground found in other power systems, set up PV solar for direct drive input to the power boards, corrected the pure sine power for real neutral/earth ground and rounding the sine wave for really clean AC power.?

I don't regret anything in building the project power system, you benefit from having a proven concept solution road map to follow. The more I do the easier it all gets. Proficient in FET upgrades,testing and CPU replacement on the power boards, New zero grid usage on a sunny day makes me smile every time I go out the back door and see it.?

Recent improvements making a real difference in the fun factor, easier to build, use green power and save, completely solved heat issue in running the mini split 24/7 off the secondary ISO transformer, on the right path after years of hit and miss testing ?

Normal operation 75.0 on top display would be the full 15Amp PV solar have witnessed 14.68 Amps without a problem, bottom display is total grid usage tiny reverse leak on a rated 15Amp diode bridge 0.01 backwards no forward flow so Zero secondary usage.

Note green indicator of the ISO transformer is off, full sun detection has opened the relay circuit to the primary coil fuse, Zero grid/secondary usage.

More soon

Not recommended by this projects 200 max voltage rule, but have heard back from the UK several 220Volt AC 50 Hz systems have been built using the same power board and 40N65 MOSFETs.

These power boards have been on the market for at least 10 years for inverter repair and upgrades to pure sine power.

The project tamed the strong bias to earth ground found in other power systems, set up PV solar for direct drive input to the power boards, corrected the pure sine power for real neutral/earth ground and rounding the sine wave for really clean AC power.?

I don't regret anything in building the project power system, you benefit from having a proven concept solution road map to follow. The more I do the easier it all gets. Proficient in FET upgrades,testing and CPU replacement on the power boards, New zero grid usage on a sunny day makes me smile every time I go out the back door and see it.?

Recent improvements making a real difference in the fun factor, easier to build, use green power and save, completely solved heat issue in running the mini split 24/7 off the secondary ISO transformer, on the right path after years of hit and miss testing ?

Normal operation 75.0 on top display would be the full 15Amp PV solar have witnessed 14.68 Amps without a problem, bottom display is total grid usage tiny reverse leak on a rated 15Amp diode bridge 0.01 backwards no forward flow so Zero secondary usage.

Note green indicator of the ISO transformer is off, full sun detection has opened the relay circuit to the primary coil fuse, Zero grid/secondary usage.

More soon

Attachments

Last edited: