mickenorlen

New Member

Hi,

I'm planning an off-grid solar setup and would like to over size my panels to maintain decent production in the winter. For the MPPT at 4kW I would like at least 5kW PV (25% over size). With 2 strings in parallel I'm worried that the short circuit current is too close to the max PV Isc of the MPPT.

These components are already purchased. The only thing missing is to decide the panel setup.

- Battery: 48V, 16 x EVE LiFePO4 3.2V => V_float = 54.4, according to this post

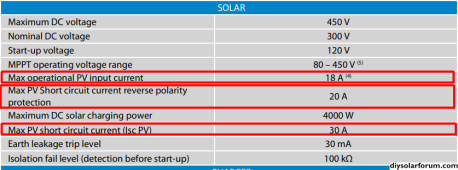

- MPPT: Victron Inverter RS 48/6000 230V Smart Solar, spec

Maximum DC solar charging power = 4000 W

Max Vsc = 8 x 54.4 = 435.2

Max operational PV input current = 18 A

Max PV Short circuit current reverse polarity protection = 20 A

Max Isc = 30A

Relevant clarifications from MPPT manual, section 3.4, link

Panels

So now I'm looking at these panels below and find these values at STC.

- Luxor, 400W, Isc: 13.60, Vsc: 37.01

- Jinko, 435W, Isc: 13,72, Vsc: 39,36

Questions

Could it cause any problems to connect them in two parallell strings, eg: 7S2P?

14 x Luxor, 5600W, Isc: 27.20, Voc: 259.07

14 x Jinko, 6090W, Isc: 27.44, Voc: 275.52 (it might be enough with 12 panels here)

The excerpt from manual above sais they allow for Isc "slightly above" the max polarity protection circuit of 20A. So I'm worried that Isc at 27.5A could stress and reduce the life expectancy of the MPPT. Given that panels can sometimes produce more than their STC specification, I'm also worried that the current could even rise beyond the absolute max Isc at 30A and cause direct damage.

Let me know if you think there are other types of panels that would be more appropriate for my use case. I'm also curious which panel you would chose of the above. Would you say the double glass design from luxor makes them superior in terms of longevity?

Thank you for your help

I'm planning an off-grid solar setup and would like to over size my panels to maintain decent production in the winter. For the MPPT at 4kW I would like at least 5kW PV (25% over size). With 2 strings in parallel I'm worried that the short circuit current is too close to the max PV Isc of the MPPT.

These components are already purchased. The only thing missing is to decide the panel setup.

- Battery: 48V, 16 x EVE LiFePO4 3.2V => V_float = 54.4, according to this post

- MPPT: Victron Inverter RS 48/6000 230V Smart Solar, spec

Maximum DC solar charging power = 4000 W

Max Vsc = 8 x 54.4 = 435.2

Max operational PV input current = 18 A

Max PV Short circuit current reverse polarity protection = 20 A

Max Isc = 30A

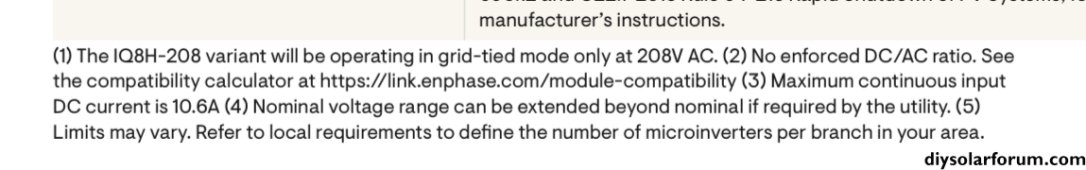

Relevant clarifications from MPPT manual, section 3.4, link

...The Inverter RS Solar single tracker model contains multiple PV input connectors. However these are internally connected to one single Maximum Power Point Tracker.

...The maximum operational input current for each tracker is 18 A.

MPPT PV inputs are protected against reverse polarity, to a maximum short circuit current of 20 A for each tracker.

Connecting PV arrays with a higher short circuit current is possible, up to an absolute maximum of 30A, as long as connected

with correct polarity. This outside of specification potential allows for system designers to connect larger arrays, and can be useful

to understand in case a certain panel configuration results in a short circuit current just slightly above the maximum of the reverse

polarity protection circuit.

The maximum open circuit voltage of the PV array must be less than 8 times the minimum battery voltage when at float.

For example, where a battery has a float voltage of 54.0 volts, the maximum open circuit voltage of the connected array cannot exceed 432 volts.

Panels

So now I'm looking at these panels below and find these values at STC.

- Luxor, 400W, Isc: 13.60, Vsc: 37.01

- Jinko, 435W, Isc: 13,72, Vsc: 39,36

Questions

Could it cause any problems to connect them in two parallell strings, eg: 7S2P?

14 x Luxor, 5600W, Isc: 27.20, Voc: 259.07

14 x Jinko, 6090W, Isc: 27.44, Voc: 275.52 (it might be enough with 12 panels here)

The excerpt from manual above sais they allow for Isc "slightly above" the max polarity protection circuit of 20A. So I'm worried that Isc at 27.5A could stress and reduce the life expectancy of the MPPT. Given that panels can sometimes produce more than their STC specification, I'm also worried that the current could even rise beyond the absolute max Isc at 30A and cause direct damage.

Let me know if you think there are other types of panels that would be more appropriate for my use case. I'm also curious which panel you would chose of the above. Would you say the double glass design from luxor makes them superior in terms of longevity?

Thank you for your help