Rednecktek

Solar Wizard

So I'm hoping to pick up a new-to-me 1999 Coleman pop-up trailer on Tuesday and I've already started thinking about how I'm going to pimp it out so I can just grab & go when I'm on this side of the mountains. I've already got on the To-Do list:

Flip the axle so I have ground clearance

Build 2 12v 280Ah batteries with heaters

Replace the propane/12v fridge with a dorm fridge

Cut bubble-wrap-mylar insulation inserts for all the windows

Replace the roof lights with LED's

Add in some USB-C PD and 2.1a outlets

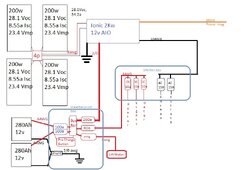

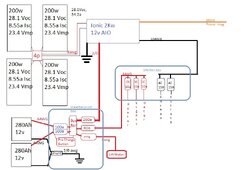

But for here, I'd like a sanity check and some input on the new electrical and solar system:

4x 10BB 200w Bi-Facial panels

2x 280Ah homemade batteries (EVE cells, JBD BMS)

Ionic 2Kw 12v AIO Solar Inverter

4p Combiner Box

LNEX Shunt

Bus Bar

AC and DC DIN rail breakers to replace the existing power center

200a Class-T for inverter

MEGA fuses for lift motor and DC bus (need to get to the data plate on the lift motor to size the fuse)

All my wire is the silicone wrapped high temp wire so I'm pretty sure all my gauges are correct.

So, a couple questions for y'all:

1: Does anyone see any glaring errors?

2: Is there any reason I can't connect the inverter Negative to the chassis?

3: While I'm mounting the panels on the roof with VHB tape and aluminum unistrut, is there any reason NOT to put down the mylar reflective coating under them? They'll be a couple-three inches off the roof.

Photo log to come (weather and Tuesday permitting)!

Flip the axle so I have ground clearance

Build 2 12v 280Ah batteries with heaters

Replace the propane/12v fridge with a dorm fridge

Cut bubble-wrap-mylar insulation inserts for all the windows

Replace the roof lights with LED's

Add in some USB-C PD and 2.1a outlets

But for here, I'd like a sanity check and some input on the new electrical and solar system:

4x 10BB 200w Bi-Facial panels

2x 280Ah homemade batteries (EVE cells, JBD BMS)

Ionic 2Kw 12v AIO Solar Inverter

4p Combiner Box

LNEX Shunt

Bus Bar

AC and DC DIN rail breakers to replace the existing power center

200a Class-T for inverter

MEGA fuses for lift motor and DC bus (need to get to the data plate on the lift motor to size the fuse)

All my wire is the silicone wrapped high temp wire so I'm pretty sure all my gauges are correct.

So, a couple questions for y'all:

1: Does anyone see any glaring errors?

2: Is there any reason I can't connect the inverter Negative to the chassis?

3: While I'm mounting the panels on the roof with VHB tape and aluminum unistrut, is there any reason NOT to put down the mylar reflective coating under them? They'll be a couple-three inches off the roof.

Photo log to come (weather and Tuesday permitting)!