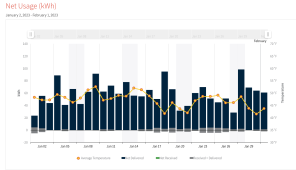

Aionrise 330w panels. It's a string of 12 sitting on the concrete Will Prowse style. I have considered the obvious things pertaining to shading, but don't want to push the issue further until I update the firmware. Time permitting. Not like I'm loosing much with the amount of cloudy days we've had lately.

To be frank, the failures are so few and far between I can't remember exactly without pulling out the RMA forms from my desk. Generally speaking we fix any issues in the field so they never need to come back to us. Thinking back on it now, a couple of them were shop testing units from last year. I know one was a return that had a bad cell that I replaced. Another had a failed temp sensor the customer wasn't comfortable replacing.

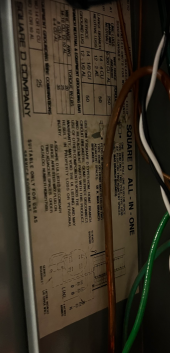

Here's a video covering some progress throughout the install. The video turned out boring. It was a lot of work, my house was without power and I wanted to get the job done. Not my finest work, but loads of detail here.