Hello Folks,

A new user here, looking for a bit of advice on electrical components to build a solar power system for my Ford Transit Van convert. I’ll describe what I would like to achieve and the components I already have, and then I’ll ask my questions. If I am missing anything, please feel free to add your opinion, I will be most grateful.

I am in the process of converting at home a 250 Ford Transit Van into a camper it comes with a single alternator. The camper will serve for short and extended trips in North and, hopefully, South Americas , 4-season use, but not intended for a full-time living. I am looking to build a reliable system for the various road conditions, including mild off-roading. I also hope to rent out the van to some friends during summer times to recoup part of the costs. Therefore it would be nice that the system I put-in would be end-user friendly and allow for remote diagnostics or at least simple(r) in operation.

, 4-season use, but not intended for a full-time living. I am looking to build a reliable system for the various road conditions, including mild off-roading. I also hope to rent out the van to some friends during summer times to recoup part of the costs. Therefore it would be nice that the system I put-in would be end-user friendly and allow for remote diagnostics or at least simple(r) in operation.

I intend to build with four 200 Wats Mono Renogy Solar panels for a total of 800 watts (ordered). The caveat here, because of the physical space limit, the panels will be placed in pairs, on top of each other. Only two panels will face the open sky, and another two panels will slide out during stationary position. The idea similar to Everlanders camper builds

, except they are using eight panels, and I’ll be using only four.

I also already ordered 8 of LifePO 280Amps cells and Victron 150/100 MPPT (150V/70Amps) controller. I am trying to re-balance my budget using a less expensive battery configuration with better quality charging and connecting components.

What I’d like to build is a system that could:

In my mind, there is a large difference in selecting electric components for a stationary location versus mobile Van systems with off-roading capabilities that are constantly under earthquake-like stress conditions, altitude, and temperature changes. I know there are tons of example YouTube videos; most don’t cover a setup similar to mine or provide reliability updates on the components used.

Finally, with panels, MPPT, and batteries, I am already down in $3K. I can probably add another $2K to the electrical part, but that’s would be a stretch. So I can’t simply choose the best-of-best on all components, somewhere I have to compromise. Therefore, I am looking for real-life experiences to share about different brands and your suggestions regarding reliability, support, and costs.

Thank you for taking your time reading all this. Of course, I don't expect someone is spending a lot of time answering all the questions or offering complete design plans for free. But if you have a piece of advice, suggestion, or want to share your experience relative to this setup, please post it, I appreciate every bit of advice I can get, and I am sure it will help other self-builders like me as well. Thank you very much again!

A new user here, looking for a bit of advice on electrical components to build a solar power system for my Ford Transit Van convert. I’ll describe what I would like to achieve and the components I already have, and then I’ll ask my questions. If I am missing anything, please feel free to add your opinion, I will be most grateful.

I am in the process of converting at home a 250 Ford Transit Van into a camper it comes with a single alternator. The camper will serve for short and extended trips in North and, hopefully, South Americas

I intend to build with four 200 Wats Mono Renogy Solar panels for a total of 800 watts (ordered). The caveat here, because of the physical space limit, the panels will be placed in pairs, on top of each other. Only two panels will face the open sky, and another two panels will slide out during stationary position. The idea similar to Everlanders camper builds

I also already ordered 8 of LifePO 280Amps cells and Victron 150/100 MPPT (150V/70Amps) controller. I am trying to re-balance my budget using a less expensive battery configuration with better quality charging and connecting components.

What I’d like to build is a system that could:

- Reliably charge ~500 Amps battery bank(s) from either - solar, shore AC, car alternator, or a 2000W portable gas generator

- Can deliver around 300-350Amps daily (approx. calculated usage)

- Allow for a direct supply of power from solar panels to a (as an example, a small (8K btu) portable air conditioner) or any AC 500-600Watts draw device (connected/turned on manually, upon arising needs)

- Be safe to operate and do not require a degree in electrical engineering to troubleshoot. I rather add/setup/configure additional safeguards, monitors, larger gauge wires or load distributions components ahead of time than trying to solve electrical issues in the middle of nowhere.

- Be a modular system allowing for upgrades, add-ons, or replacements of the components. For example, I may carry a couple extra 100 Watt flex solar panels to add to the config on a very hot sunny day to make an AC work; if the panels I will mount to the roof may not be sufficient.

- Be cost-efficient with some reliability buffer. It acceptable to me to pass a learning curve ahead of the build and have some components as configured spares, but at the half-cost, comparing to using a single component from a top brand but a hugely over-priced and no easy access to a spare.

- Solar panels wiring for my configuration (2 open, 2 open on demand, with the ability to add another 1-2) – Serial, Parallel, or S/P? Btw, I live and travel mostly in a shady and cloudy region (BC, Canada). I understand how power is calculated, but I can’t predict how it will practically vary with panel pairs added or removed.

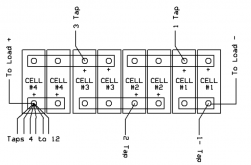

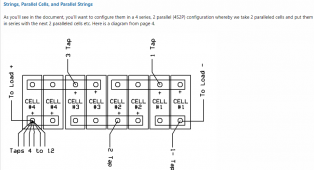

- The battery cell connection for eight LIFEPO4 cells – S/P/4s2P/4P2s? One bank or two banks with a single MPPT? Once again, accounting for the solar panel positions (open/close in pairs). I want those batteries setup to last longer, given the fact sun is not always shining around us. 12V or 24V? Even so I like the benefits of 24v system, I am concern that my single 12V alternator will have to work hard to charge up the house batteries even with a proper DC-to-DC converter. Ford Transit comes with two batteries already. Therefore, I would like solar panels to be used for charging as the first option while driving and as a second option, alternator, manually engaged for charging.

- I have a 3000W Modified Sine Inverter with a remote shutdown port, which has been sitting on a shelf for a year now. Would this work, or a pure sine is a requirement?

- Additional (to MPPT controller components)– BMS, DC-to-DC charger, battery balancer or isolator. Which components under this setup will be a must-have and which ones will be nice to have (if this will make the management easier). Is there a company besides Victron that provides reasonably reliable components? I am not a fan on the idea of using an all-in-one charging inverter/controller simply because of lack of redundancy. In case of one charging component failure, I would like to have at least one other working option to charge the batteries, like from a generator or alternator or both.

- What about BMS? What size would I need for my 8 cells 280Amps? Should I go with Electrodacus SBMS0 or is there a sufficient Victron BMS or one from Overkill Solar? I am still confused because most BMS listing on specs 4 cells for 12V systems or 8 cells but 24V. Also, trying to grasp the AMP capacity my BMS must have. Unfortunately, I find almost no builds or documented examples with LifePO4 with 8 cells and 12V for Van builds.

In my mind, there is a large difference in selecting electric components for a stationary location versus mobile Van systems with off-roading capabilities that are constantly under earthquake-like stress conditions, altitude, and temperature changes. I know there are tons of example YouTube videos; most don’t cover a setup similar to mine or provide reliability updates on the components used.

Finally, with panels, MPPT, and batteries, I am already down in $3K. I can probably add another $2K to the electrical part, but that’s would be a stretch. So I can’t simply choose the best-of-best on all components, somewhere I have to compromise. Therefore, I am looking for real-life experiences to share about different brands and your suggestions regarding reliability, support, and costs.

Thank you for taking your time reading all this. Of course, I don't expect someone is spending a lot of time answering all the questions or offering complete design plans for free. But if you have a piece of advice, suggestion, or want to share your experience relative to this setup, please post it, I appreciate every bit of advice I can get, and I am sure it will help other self-builders like me as well. Thank you very much again!