That should make installation easier too. Any restrictions running THHN through flex conduit ?If you ever have to unmount/reinstall SolArk for repair, wouldn't rigid conduit make it difficult?

Can wiring trough be swung down to uncouple?

Sufficient gap between inverter/trough and flexible conduit would let each connection be pulled out individually.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Sol-Ark 15K All in One Inverter Released.

- Thread starter robby

- Start date

On a related note... I'm going to be installing my 15k soon in the basement. All of the wiring will be coming down from a suspended ceiling, except the 48V battery/cables which will be on a shelf next to the SA. What's the recommend way to run the AC and high voltage DC wiring along the 1st floor joists and down into the SA?

Hedges

I See Electromagnetic Fields!

- Joined

- Mar 28, 2020

- Messages

- 21,070

That should make installation easier too. Any restrictions running THHN through flex conduit ?

Conduit is conduit, so far as I know.

I use flexible water-tight conduit outside (aluminum with plastic exterior.) The aluminum or steel stuff without plastic should be fine inside.

Bending radius is kind of large. Good to have enough room to pull wires back from box at the same time. Offset so there is a rotation, not just a bend, may make it easier.

Egl_81

New Member

- Joined

- Mar 10, 2022

- Messages

- 36

Yes it would. The trough was kind of a pain to mount and line up all the conduit, but I did it once, I can do it again if I ever have to. Personally, I like the EMT conduit from the trough to the sol-ark for aesthetics, and using EMT allowed me to line up conduit on one end and let it "hang" from it while I lined up the rest. Flex might or might not make it easier.If you ever have to unmount/reinstall SolArk for repair, wouldn't rigid conduit make it difficult?

Can wiring trough be swung down to uncouple?

Sufficient gap between inverter/trough and flexible conduit would let each connection be pulled out individually.

Egl_81

New Member

- Joined

- Mar 10, 2022

- Messages

- 36

As long as your DC is in metallic conduit of some sort, no. I used liquidtight metallic flex for my run from the roof to the basement.That should make installation easier too. Any restrictions running THHN through flex conduit ?

Yes it would. The trough was kind of a pain to mount and line up all the conduit, but I did it once, I can do it again if I ever have to. Personally, I like the EMT conduit from the trough to the sol-ark for aesthetics, and using EMT allowed me to line up conduit on one end and let it "hang" from it while I lined up the rest. Flex might or might not make it easier.

That just gave me an idea. Why not make slits/slots on back of trough to screw through. Then installation and future removal of equipment would be easier.

Just unscrew anchor screws and then lossen the screws in the slots to slide the trough down.

I believe it’s only the PV DC that needs to be protected once inside or in contact with the building. DC 48v (less than 60) battery is probably exempt from that.As long as your DC is in metallic conduit of some sort, no. I used liquidtight metallic flex for my run from the roof to the basement.

Egl_81

New Member

- Joined

- Mar 10, 2022

- Messages

- 36

Yes I believe that's correct, just the high voltage DC needs to be in metallic conduit. Battery cables can actually be in free air.I believe it’s only the PV DC that needs to be protected once inside or in contact with the building. DC 48v (less than 60) battery is probably exempt from that.

I just got my Solark Installed and Grid and Load wiring installed in basement. Neutral on Neutral Bar, Ground on Ground bar. I was quite surprised when as soon as the power was turned on, (with the Solark Load connected to my Transfer switch, and left open so the Solark will not see any load...) that the Solark front panel lit up, and it started beeping at me. Note that the Power Switch on the side of the unit was OFF, and all of the circuit breakers inside were also OFF for both load and grid.

I guess this behavior is "normal" as I am 10000% sure the 4/0 Al wire is installed correctly, but I was shocked that it "came to life" with just power supplied to the Grid input (from the fused cut off switch out by the meter)... and the load going to an "open circuit" connection inside a transfer switch.

It had all kinds of alarms and errors that made no sense, and I watched a Solark start up video that began with two installers laughing and asking how to turn off the "beeping" alarms. So I turned the "beep off".

Any suggestions on next steps.. and can someone describe how the "pass through" of the 200A grid feed works please. I assume that is what I am observing, and if I turn on all the breakers, and leave the Solark powered down, it will begin to "pass through" the 200A of AC to the transfer switch, and if I switch that down it will power the house as planned.

Thanks in advance to anyone who has been through this.. as I said when the front panel lit up, even with it powered off and all the circuit breakers off I was quite surprised.

CPU

I guess this behavior is "normal" as I am 10000% sure the 4/0 Al wire is installed correctly, but I was shocked that it "came to life" with just power supplied to the Grid input (from the fused cut off switch out by the meter)... and the load going to an "open circuit" connection inside a transfer switch.

It had all kinds of alarms and errors that made no sense, and I watched a Solark start up video that began with two installers laughing and asking how to turn off the "beeping" alarms. So I turned the "beep off".

Any suggestions on next steps.. and can someone describe how the "pass through" of the 200A grid feed works please. I assume that is what I am observing, and if I turn on all the breakers, and leave the Solark powered down, it will begin to "pass through" the 200A of AC to the transfer switch, and if I switch that down it will power the house as planned.

Thanks in advance to anyone who has been through this.. as I said when the front panel lit up, even with it powered off and all the circuit breakers off I was quite surprised.

CPU

cmack

New Member

Any 15k users getting frequent grid disconnections? I am getting 5-10 disconnects per day at random times. Sometimes they last for hours, which is a major problem at night. My batteries get drawn down and my CLP loses power. Waking up to an alarm at 4am is very unsettling!

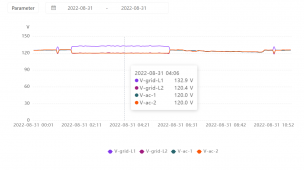

I'm told by support that it's a problem with my grid voltage, and they are looking into a software solution. In the attached screenshot you can see the grid voltages change from ~125 each, to ~120/133. During these periods the SA will disconnect itself from grid, and will not allow pass through.

I'm told by support that it's a problem with my grid voltage, and they are looking into a software solution. In the attached screenshot you can see the grid voltages change from ~125 each, to ~120/133. During these periods the SA will disconnect itself from grid, and will not allow pass through.

Attachments

Solar Guppy

Red Cobra Guppy

I just got my Solark Installed and Grid and Load wiring installed in basement. Neutral on Neutral Bar, Ground on Ground bar. I was quite surprised when as soon as the power was turned on, (with the Solark Load connected to my Transfer switch, and left open so the Solark will not see any load...) that the Solark front panel lit up, and it started beeping at me. Note that the Power Switch on the side of the unit was OFF, and all of the circuit breakers inside were also OFF for both load and grid.

Inverters are power by the batteries ( or solar with some brands ), not the AC lines, so that is likely what you are seeing

Balthazar-B

New Member

- Joined

- Jun 11, 2022

- Messages

- 91

Any 15k users getting frequent grid disconnections? I am getting 5-10 disconnects per day at random times. Sometimes they last for hours, which is a major problem at night. My batteries get drawn down and my CLP loses power. Waking up to an alarm at 4am is very unsettling!

I'm told by support that it's a problem with my grid voltage, and they are looking into a software solution. In the attached screenshot you can see the grid voltages change from ~125 each, to ~120/133. During these periods the SA will disconnect itself from grid, and will not allow pass through.

To clarify, is "support" from Sol-Ark, or from your grid provider?

Most out-of-spec voltage fluctuations on the grid need to be fixed by the utility. Depending on how things work in Ontario (or don't), it might take nothing more than a letter to your provider, and cc'd to their regulator. Remediation on your side of the meter may be difficult to impossible. I've heard of voltage regulators being applied in areas where grids are as reliable as an employee with an opoid problem, but not an area I'm familiar with. You may find this linked article interesting for context. Not from Canada, but at least from another Commonweath country:

ETA: Just to check that you've got maximum stability as much as possible on your side of the meter, this would be a good time to confirm based on your actual consumption that the two legs of your split-phase topology are optimally balanced in terms of loads.

Last edited:

chess-equality

Solar Enthusiast

- Joined

- May 21, 2022

- Messages

- 500

Any 15k users getting frequent grid disconnections? I am getting 5-10 disconnects per day at random times. Sometimes they last for hours, which is a major problem at night. My batteries get drawn down and my CLP loses power. Waking up to an alarm at 4am is very unsettling!

I'm told by support that it's a problem with my grid voltage, and they are looking into a software solution. In the attached screenshot you can see the grid voltages change from ~125 each, to ~120/133. During these periods the SA will disconnect itself from grid, and will not allow pass through.

I'm not a Sol-Ark user, but earlier this year we had the problem of a failing power meter that we were getting cut-offs and fluctuations. It took two technicians to finally identify the problem, and we had the meter replaced by the utility (for free).

cmack

New Member

Sol-Ark support. I will get in touch with my utility as well, thanks for the suggestion.To clarify, is "support" from Sol-Ark, or from your grid provider?

I have factory settings for grid voltage (265 high, 185 low) and the disconnects are happening around 255v. That's odd, no?

RCinFLA

Solar Wizard

- Joined

- Jun 21, 2020

- Messages

- 3,566

If you are getting 133vac and 120vac between L1-N and L2-N, that is a sign of neutral connection issue.

The L1-N and L2-N is a local issue that can only be caused between your output point and utility pole transformer. Most common point of issue is the bare uninsulated support cable connection coming into house which is the neutral wire back to utility pole transformer. Sometimes it is poor neutral cable connection at the main panel, but it can be any neutral connection between you and the utility transformer neutral connection.

With poor neutral connection, your neighbors, on the same pole transformer 240vac connection, can affect your 120vac phase voltage split.

The inverter may complain if the 120vac phase voltage matching is too far off.

Issue with a neutral connection trouble shooting is it can be on utility side responsibility or on your side of weather head entrance which is your responsibility. Meter is owned by utility, but the meter box and its socket is your responsibility.

Sometimes you get into a 'finger pointing' situation on whom needs to trouble shoot it. Most of the time utility is helpful since they don't want to get challenged to pay for a new refrigerator because their neutral cable had a bad connection.

The L1-N and L2-N is a local issue that can only be caused between your output point and utility pole transformer. Most common point of issue is the bare uninsulated support cable connection coming into house which is the neutral wire back to utility pole transformer. Sometimes it is poor neutral cable connection at the main panel, but it can be any neutral connection between you and the utility transformer neutral connection.

With poor neutral connection, your neighbors, on the same pole transformer 240vac connection, can affect your 120vac phase voltage split.

The inverter may complain if the 120vac phase voltage matching is too far off.

Issue with a neutral connection trouble shooting is it can be on utility side responsibility or on your side of weather head entrance which is your responsibility. Meter is owned by utility, but the meter box and its socket is your responsibility.

Sometimes you get into a 'finger pointing' situation on whom needs to trouble shoot it. Most of the time utility is helpful since they don't want to get challenged to pay for a new refrigerator because their neutral cable had a bad connection.

Last edited:

Hedges

I See Electromagnetic Fields!

- Joined

- Mar 28, 2020

- Messages

- 21,070

I agree it sounds like neutral issue, and the graph proves it (what's lost from one phase appears at the other.)

Check the voltages with a meter, back at your service entrance.

If same issue there, it is on the utility side. If OK at service entrance but low at sol-ark it is some where in between so check at each point. Likely more pronounced at higher current draw. This could be due to other parts of the house, drawing current through connections common with Sol-Ark.

Check the voltages with a meter, back at your service entrance.

If same issue there, it is on the utility side. If OK at service entrance but low at sol-ark it is some where in between so check at each point. Likely more pronounced at higher current draw. This could be due to other parts of the house, drawing current through connections common with Sol-Ark.

cmack

New Member

I noticed this browning on the neutral coming in to my main panel. Maybe an indication of an issue?

Would this connection point be considered the service entrance?check the voltages with a meter, back at your service entrance.

Attachments

Hedges

I See Electromagnetic Fields!

- Joined

- Mar 28, 2020

- Messages

- 21,070

And melting.

You've almost certainly found the issue.

I see this lug also has ground bond.

Check voltages at lugs (should be good), on wire strands or down at next box (should show the deviation.)

While tightening may be sufficient, best to power off, cut end of wire to a fresh section.

You could clean up surface inside lug, but don't scrape off tin plate (exposing bare aluminum).

Red and Black also. I see melted insulation. Tighten ground as well (no need to strip if no melting.)

Stranded wires tend to settle under screw, need repeated re-torquing. Use a torque wrench if available, otherwise by feel.

I swing end of wire so it rotates under the screw and keep snugging until screw stops turning.

Corrosion inhibitor could help (but not with the torque/settling issue, only corrosion.)

You've almost certainly found the issue.

I see this lug also has ground bond.

Check voltages at lugs (should be good), on wire strands or down at next box (should show the deviation.)

While tightening may be sufficient, best to power off, cut end of wire to a fresh section.

You could clean up surface inside lug, but don't scrape off tin plate (exposing bare aluminum).

Red and Black also. I see melted insulation. Tighten ground as well (no need to strip if no melting.)

Stranded wires tend to settle under screw, need repeated re-torquing. Use a torque wrench if available, otherwise by feel.

I swing end of wire so it rotates under the screw and keep snugging until screw stops turning.

Corrosion inhibitor could help (but not with the torque/settling issue, only corrosion.)

cmack

New Member

I'm not comfortable messing around in there while it's live so I will need to request a disconnect and subsequent ESA inspection. Should I check with hydro company to verify their end is good before doing this?While tightening may be sufficient, best to power off, cut end of wire to a fresh section.

Solar Guppy

Red Cobra Guppy

And melting.

You've almost certainly found the issue.

I see this lug also has ground bond.

Check voltages at lugs (should be good), on wire strands or down at next box (should show the deviation.)

While tightening may be sufficient, best to power off, cut end of wire to a fresh section.

You could clean up surface inside lug, but don't scrape off tin plate (exposing bare aluminum).

Not to leave anything to chance, make sure there is NO voltage on the mains before doing anything ( wires in your photo of concern ). Most homes there is NO disconnect from the utility meter to the main panel, so those lugs would be hot 24/7.

In theory you could trip the main breaker and then torque down the loose neutral, but you better have proper gloves and cover the hot legs, not recommended unless you have done this type of work before. Usually electricians will just pull the meter to work on these lines to be safe, then call the utility to replace the tamper tag.

Similar threads

- Replies

- 4

- Views

- 291

- Replies

- 25

- Views

- 1K

- Replies

- 17

- Views

- 846