ThanksThat was 4 strings at ~300V @20A and 1 string at 350V @ 20A. I now have all 6 strings hooked up. 4 are ~350VOC and 2 are ~400VOC.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Sol-Ark 15k will only invert 13k of DC PV to AC

- Thread starter Clint-L

- Start date

Oh okay. Got it. Ya this whole thing is just weird to me. Doesn’t make sense.Yep, that's how mine is setup.

robby

Photon Vampire

- Joined

- May 1, 2021

- Messages

- 4,129

Typically when you get to this point (meaning a second unit displaying issues) it's time to start looking at the fundamentals of the installation and see if something very basic is wrong.Oh okay. Got it. Ya this whole thing is just weird to me. Doesn’t make sense.

I would start with the PV wiring and make sure the negative lead from one array has not been mixed up with another. Then you have fuses or breakers on the PV that may be new but are not making proper contact. Possibly a cable that was pulled to hard through the conduit and broke most of it's strands. Change the fuse holders and fuses or breakers and any combiner boxes. Test individual Panels and see how many amps they put out. It could also be a couple of bad MC4 connectors in the string.

It's all very painful but it's better than looking in the same direction.

I remember putting up a C-Band Satellite system in the mid 1990's and spending two weeks changing out Receivers, LNB's and doing all sorts of trouble shooting because the signal kept dropping out on the customer the night after we would leave thinking the problem was solved.

In the end it ended up being a the new coax cable inside the conduit. One of the guys had pulled on it really hard and had broken the center conductor. It would make contact in the day but at night I suspect the copper would shrink a little with cooler temps and break the contact.

After the five to six trips to this guys house I just decided to start it over like a new installation and assume nothing. We Yanked out the cables and that was when I saw the stretch marks on the outer casing and sure enough with a new cable run everything was fine.

Hedges

I See Electromagnetic Fields!

- Joined

- Mar 28, 2020

- Messages

- 20,682

Typically when you get to this point (meaning a second unit displaying issues) it's time to start looking at the fundamentals of the installation and see if something very basic is wrong.

I would start with the PV wiring and make sure the negative lead from one array has not been mixed up with another. Then you have fuses or breakers on the PV that may be new but are not making proper contact. Possibly a cable that was pulled to hard through the conduit and broke most of it's strands. Change the fuse holders and fuses or breakers and any combiner boxes. Test individual Panels and see how many amps they put out. It could also be a couple of bad MC4 connectors in the string.

It's all very painful but it's better than looking in the same direction.

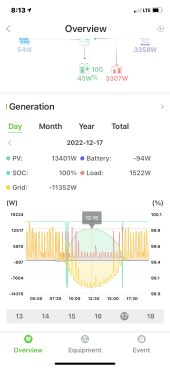

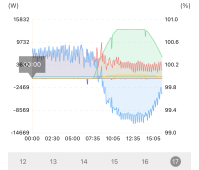

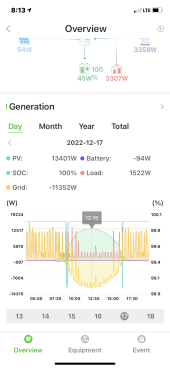

The graph with flat top tells a different story. Something decides to draw no more from PV.

Appears to simply be a programmed limit.

Not like this graph, which is limited by available PV.

(and happens to be no higher than the above graph; have to see how it behaves with more PV or more sun.)

robby

Photon Vampire

- Joined

- May 1, 2021

- Messages

- 4,129

Totaly agree but when you know that the Inverter works for other people and your on the second unit with no luck maybe there is some sort of other problem. I am not sure what would happen if the negatives from one Array were mixed up with another. I suspect no power at all but do you have any insight on that?The graph with flat top tells a different story. Something decides to draw no more from PV.

Appears to simply be a programmed limit.

View attachment 125202

Not like this graph, which is limited by available PV.

(and happens to be no higher than the above graph; have to see how it behaves with more PV or more sun.)

View attachment 125203

robby

Photon Vampire

- Joined

- May 1, 2021

- Messages

- 4,129

Core operation bugs typically only happen with cheap products. With well made products there are typically no bugs in the core operation of the product. Those kind of bugs would kill the sales of a high priced product almost instantly and could flush months or years of R&D money on the product down the toilet and also damage the companies reputation. Thats why they test them to death before releasing them!Philosophy is to get the product out there and let the customers help find the bugs for them.

They can always push a new firmware load at a later date.

There are always going to be Bugs that you cannot find using a limited Beta testing group but they will become exposed when thousand of people start to use the product in various manors and configurations.

None of them will be major enough to effect the main features of the inverter.

Koldsimer

Solar Addict

- Joined

- Dec 4, 2021

- Messages

- 604

I can't believe how problematic some of these cheaper inverters are. I have a Schneider xw that has never given me an issue in nearly 3 years of service. Lots of users out there that have 20+ years of trouble free service from their Trace/Xantrex/Schneider products.Core operation bugs typically only happen with cheap products. With well made products there are typically no bugs in the core operation of the product. Those kind of bugs would kill the sales of a high priced product almost instantly and could flush months or years of R&D money on the product down the toilet and also damage the companies reputation. Thats why they test them to death before releasing them!

There are always going to be Bugs that you cannot find using a limited Beta testing group but they will become exposed when thousand of people start to use the product in various manors and configurations.

None of them will be major enough to effect the main features of the inverter.

Same thing with your Sol-Ark. It does stuff that other inverters just can't do and it works perfectly for your needs.

In general, it appears that you get what you pay for with inverters, charge controllers, etc..

Hedges

I See Electromagnetic Fields!

- Joined

- Mar 28, 2020

- Messages

- 20,682

There are always going to be Bugs that you cannot find using a limited Beta testing group but they will become exposed when thousand of people start to use the product in various manors and configurations.

None of them will be major enough to effect the main features of the inverter.

It happens, though, if there is not automation or discipline to test basic functions. Maybe not to the #1 main feature.

Something that once worked can get broken in future versions; "regression testing" is needed.

I found one in Sunny Boy 10000TL-US.

It has three operating modes: On-grid, grid-backup, off-grid.

In grid-backup and off-grid, as frequency increases it is supposed to ramp down output power.

When switched to grid-backup it did remain connected over the wider frequency range, but at 100% power.

Likely most installations were strictly on-grid, and some off-grid, with very few using grid-backup.

If any did, it would have seemed fine at first, with battery inverter taking 100%. But once near full, it cycles on and off. Functional but not good.

Possibly installers observed that and set it to off-grid, even though grid connection was present. Nothing bad seems to happen, but I've read the battery inverter sometimes gets stuck relays, which in this case would result in no anti-islanding.

RCinFLA

Solar Wizard

- Joined

- Jun 21, 2020

- Messages

- 3,564

Inverter like the Schneider XW has quite complicated firmware. They have had their share of bugs but have had ten years to work through them.

It is a very good product, but I always thought their software process control was a bit lacking.

It is a very good product, but I always thought their software process control was a bit lacking.

Solar Guppy

Red Cobra Guppy

Inverter like the Schneider XW has quite complicated firmware. They have had their share of bugs but have had ten years to work through them.

It is a very good product, but I always thought their software process control was a bit lacking.

More like 18 years

As far as process, it was quite good when the original design team was involved ( I was part of that ), but as people come and go and then the purchase by Schneider Electric trying to reverse engineer a products software can be near impossible, it is literally having to learn all over what was done.

Compare to companies from the East that just drop the product every 18-24 months support wise and don't respond to end-users at all. That is why the XW is still around and nothing better all these years later and is still the top choice for professional installers whom just didn't start working in Solar thinking installing bug ladened products is OK.

I can get 6,400 watts of DC on any two of the three arrays. Plug in a third and they all throttle down to about 14.~ amps each.

If I disconnect one of the three arrays the other two will raise to 6.4kw and produce their potential full amount during full sun (on good day). I’ve tested this so many times. This proves that each array is wired correctly or it couldn’t get the 6.4kw on its own when others are not connected. I have three arrays and each are 6.4kw.

Another way to say this is when all three MPPT’s have an array of 6.4kw max connected to them they all throttle and cap out at just over 14 amps each. I can remove any one of the PV arrays from the inputs (disconnect one MPPT) and only run on two inputs and magically the other two will harvest 21~ amps and each.

I don’t believe it’s a wiring issue, as I can 100% prove that each array alone produces 6.4kw and the Sol-ark inverts it etc. it just won’t do over about 13.4kw with all three connected.

Yet another way to say it - 6400 + 6400 = 13.2 and the unit does that with no issue. This is more of an issue of the arrays balancing out on the MPPT throttling at 14.~ amps per MPPT input.

If I disconnect one of the three arrays the other two will raise to 6.4kw and produce their potential full amount during full sun (on good day). I’ve tested this so many times. This proves that each array is wired correctly or it couldn’t get the 6.4kw on its own when others are not connected. I have three arrays and each are 6.4kw.

Another way to say this is when all three MPPT’s have an array of 6.4kw max connected to them they all throttle and cap out at just over 14 amps each. I can remove any one of the PV arrays from the inputs (disconnect one MPPT) and only run on two inputs and magically the other two will harvest 21~ amps and each.

I don’t believe it’s a wiring issue, as I can 100% prove that each array alone produces 6.4kw and the Sol-ark inverts it etc. it just won’t do over about 13.4kw with all three connected.

Yet another way to say it - 6400 + 6400 = 13.2 and the unit does that with no issue. This is more of an issue of the arrays balancing out on the MPPT throttling at 14.~ amps per MPPT input.

Solar Guppy

Red Cobra Guppy

I can get 6,400 watts of DC on any two of the three arrays. Plug in a third and they all throttle down to about 14.~ amps each.

It is clear that Sol-Ark didn't design the firmware, otherwise they would know where the limit is coming from. Your issue is real and is likely buried in some setting unknown to anyone but the original code writers. One would need the source code, running with a Jtag pod to find out what hidden gem is causing this, could be some left over bit not initialized in the flash memory or a configuration setting hidden from view in user mode.

It's hard enough for companies that actually design the hardware and software to find these anomalies in the field, and when your dealing with contracted engineering, close to impossible to resolve by the ones that sell the products.

Keep this in mind if your really going to sell to end users this for a solution and you become the support ( last one that touched the product is it! )

I’m to the point of just adding some micro inve

Hence many of these limits. I find it interesting that the daily PV generation graph doesn’t go to 15k on the Sol-ark 15k. Seriously, it’s pretty sloppy or lazy (one or the other) that they didn’t change that or missed it.

I’ve not seen any evidence of a graph showing a full 15k of PV production from a single Sol-ark 15k. Solark hasn’t even shared one with me. There was a guy on this thread that has two in parallel producing close to limit, but they are in parallel. I’d sure like to see a graph maxing out and flatlining at 15k!

We have discontinued selling any Sol-ark products due to this mess. I agree about the code. I believe they are running the same code or just a repackaged of the same on the 15k that they ram on the 12k.It is clear that Sol-Ark didn't design the firmware, otherwise they would know where the limit is coming from. Your issue is real and is likely buried in some setting unknown to anyone but the original code writers. One would need the source code, running with a Jtag pod to find out what hidden gem is causing this, could be some left over bit not initialized in the flash memory or a configuration setting hidden from view in user mode.

It's hard enough for companies that actually design the hardware and software to find these anomalies in the field, and when your dealing with contracted engineering, close to impossible to resolve by the ones that sell the products.

Keep this in mind if you’re really going to sell to end users this for a solution and you become the support ( last one that touched the product is it! )

Hence many of these limits. I find it interesting that the daily PV generation graph doesn’t go to 15k on the Sol-ark 15k. Seriously, it’s pretty sloppy or lazy (one or the other) that they didn’t change that or missed it.

I’ve not seen any evidence of a graph showing a full 15k of PV production from a single Sol-ark 15k. Solark hasn’t even shared one with me. There was a guy on this thread that has two in parallel producing close to limit, but they are in parallel. I’d sure like to see a graph maxing out and flatlining at 15k!

Solar Guppy

Red Cobra Guppy

I’m to the point of just adding some micro inve

We have discontinued selling any Sol-ark products due to this mess. I agree about the code. I believe they are running the same code or just a repackaged of the same on the 15k that they ram on the 12k.

Hence many of these limits. I find it interesting that the daily PV generation graph doesn’t go to 15k on the Sol-ark 15k. Seriously, it’s pretty sloppy or lazy (one or the other) that they didn’t change that or missed it.

I’ve not seen any evidence of a graph showing a full 15k of PV production from a single Sol-ark 15k. Solark hasn’t even shared one with me. There was a guy on this thread that has two in parallel producing close to limit, but they are in parallel. I’d sure like to see a graph maxing out and flatlining at 15k!

Unfortunately this is the current business model. Find a Chinese manufacture to make a product for you, usually some fork of a current product, slap on your logo and your now in the business.

I've had some inside views of what's going on, from multiple companies. The only ones doing real US based engineering are those that have 8/9 figure R&D budgets and their products like wise are the most expensive ( purchase price ) on the market.

The Chinse are only concerned about shipping and getting paid. They do not have any testing outside of in house labs. The reason these issues show up in the field is simple, they don't live like we do in the West. These products are to have power plants in single family homes, in the east, most live in towers of apartments ( owned and rented ) that these products will never be used in.

Products need to be used in the actual end use locations by your own engineers and employee's, long before paying end users start installing them, it really is that simple. Unfortunately the current model of going low cost and just rebranding doesn't do any of this.

Bits-N-Nibbles

New Member

- Joined

- May 19, 2022

- Messages

- 5

I have to agree with parts of Solar Guppy's reply. This definitely looks like an artificial limit caused by software/firmware based on Clint's testing and graphs provided (I would think even Sol-Ark would have to agree the plateau on the graph is pretty damning). Not sure I would proscribe it to either laziness, sloppiness, or current Chinese-manufacturer-first business models though. The truth is, even if the Sol-Arks are partially put together in China, they're using Japanese, Taiwanese, and looks like even American-engineered chips and parts. Many of these parts contain their own closed-source firmware that engineers just have to trust based on documentation. Don't get me started on embedded Operating Systems providing the foundation for it all, or the pages of main CPU errata that could cause any number of bugs. Likely this is the result of a bug somewhere in the complex system-of-systems that is the Sol-Ark (and most embedded devices currently produced). Short of hooking up a JTAG live, would be, and I'm surprised that Sol-Ark engineering hasn't asked for this from Clint already, a full abort/memory dump immediately after full production on all 3 MPTTs. They would still be looking for a needle in a haystack, however you at least give yourself the chance to debug any potential bitflips, or unintentionally partial mem initialization or use-after-free or some such bugs. All this assuming that the Sol-Ark that they ship to customers is even allowed to write a memory dump to a USB flash or some other customer-accessible storage (unlikely, but you never know).

Quattrohead

Solar Wizard

I think many companies have become sloppy with software because they know they can update it later in the field after the end user has debugged it. With the solark 15K I think they have just used the 12K software.

GM and Ford both think they can update their knackered 8 and 10 speed automatic transmissions with software, they don't give a shit about the fucked up hardware.

GM and Ford both think they can update their knackered 8 and 10 speed automatic transmissions with software, they don't give a shit about the fucked up hardware.

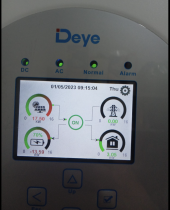

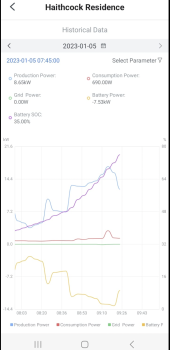

Are Deye nice and reliable inverters?Someone who got the Deye 16KW shared this on Deye users facebook group

View attachment 127988

View attachment 127989

Similar threads

- Replies

- 4

- Views

- 186

- Replies

- 0

- Views

- 172