All thicknesses upto 10mm, 220A machine with hf startWhat are you welding and does the TIG have AC high frequency?

What thickness of material?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tig welding

- Thread starter Alandall1

- Start date

Not businesss just making and selling stuffThat was going to be another question. If your doing this for personal or running a small business. If business could the equipment be a written off as upgrades?

73powerstroke

Solar Enthusiast

Probably just buy a miller bobcat ? they do tig. Or a Lincoln GenI just bought a big propane generator way less money in the long run I think. Really how long do you plan to weld? Even if all day a few times a month. for example I pay $2.60 a gallon. Burn 4-5 gallons a month? Still going to be way cheaper then a $6k inverter 5k in batteries and $3-4k in panels.

I have old miller's ones 500 pounds 300amp dialarc hf tig and a econotwin hf . I wouldn't ever try to run any of my welders off solar. Definitely would by a motor driven truck mounted unit before

It mainly about noise, i dont like it ,neither do the neighbours, and for the price if a genweld set i can buy a lot of solarProbably just buy a miller bobcat ? they do tig. Or a Lincoln Gen

I have old miller's ones 500 pounds 300amp dialarc hf tig and a econotwin hf . I wouldn't ever try to run any of my welders off solar. Definitely would by a motor driven truck mounted unit before

73powerstroke

Solar Enthusiast

Yep 200a is asking alot. My miller dialarc hf is capable of 310 amps IF YOU CAN SUPPLY 90AMPS. Unless welding big aluminum 310 is ridiculous. 60 amps at 240v is alot200A on TIG with AC high frequency?

I can tell you my TIG will blow a 60A breaker if you crank it up.

73powerstroke

Solar Enthusiast

For the price of used or even new one is cheaper. I see them all the time for 3k or less. A Hobart new is very affordable.It mainly about noise, i dont like it ,neither do the neighbours, and for the price if a genweld set i can buy a lot of solar

Expecting 200amps off solar is optimistic. You probably need 60-80 amps at 240v . That's alot.

The kind of money it takes to do that is not cheap. You need 240v at 100amp if you hope to do anything else whatsoever.

Good luck with whatever you decide.

Zwy

Emperor Of Solar

It was in my old shop, I had a 60A 240V breaker panel installed to supply a welder outlet.Yep 200a is asking alot. My miller dialarc hf is capable of 310 amps IF YOU CAN SUPPLY 90AMPS. Unless welding big aluminum 310 is ridiculous. 60 amps at 240v is alot

I got some heavy aluminum plate and was running HF for a few minutes before it tripped the breaker.

Spool gun got the job done.

Never tried heavy plate at the new shop with that Squarewave TIG and HF but that welder likes some serious amps if you crank it up.

Don't know what the member intends to weld but this is one of those items I'd leave grid powered, he might get by with a suitcase or spoolgun on solar powered off MIG but 200A on TIG with HF isn't going to cut it. I own a Trailblazer too, doesn't have HF however.

73powerstroke

Solar Enthusiast

My neighbor has a miller trailblazer. Never uses it. Has no leads. It's in his truck for looks in my opinion.It was in my old shop, I had a 60A 240V breaker panel installed to supply a welder outlet.

I got some heavy aluminum plate and was running HF for a few minutes before it tripped the breaker.

Spool gun got the job done.

Never tried heavy plate at the new shop with that Squarewave TIG and HF but that welder likes some serious amps if you crank it up.

Don't know what the member intends to weld but this is one of those items I'd leave grid powered, he might get by with a suitcase or spoolgun on solar powered off MIG but 200A on TIG with HF isn't going to cut it. I own a Trailblazer too, doesn't have HF however.

But the bobcat has hf or square wave or scratch start or something. The guy I got my dialarc hf 310 from had 2 of them. He preferred the Lincoln square wave like you mentioned.

I usually use the econotwin hf since it goes to 150 and won't trip my 60amp breaker. Aluminum likes big power. And it's not something I want to try on a hf inverter personally. Somebody could spend a lot of money on batteries and inverters (the panels are the cheap part) only to realize that they cannot run it and have spent twice as much as it would have costed it would have costed to either buy a buy a generator and run it or a motor driven welder

I dissagree, the cheapest new mobile acdc machine in NZ is over 20k and still have the noise to deal with.For the price of used or even new one is cheaper. I see them all the time for 3k or less. A Hobart new is very affordable.

Expecting 200amps off solar is optimistic. You probably need 60-80 amps at 240v . That's alot.

The kind of money it takes to do that is not cheap. You need 240v at 100amp if you hope to do anything else whatsoever.

Good luck with whatever you decide.

Secondly, a single phase machine welds at 200A it doesnt draw 200A fro a 240v supply !, startup might only be 26A and running could be 15A, all achievable on batteries

Zwy

Emperor Of Solar

I've a multitude of welders over the years. HF TIG at 200A will draw more than 26A on 240V. This isn't a buzz box with stick.I dissagree, the cheapest new mobile acdc machine in NZ is over 20k and still have the noise to deal with.

Secondly, a single phase machine welds at 200A it doesnt draw 200A fro a 240v supply !, startup might only be 26A and running could be 15A, all achievable on batteries

Page 10 here: https://www.lincolnelectric.com/assets/servicenavigator-public/LINCOLN3/IM895.pdf

Read here, once you start getting up in output, there should be a 100A breaker and the right size wires from it to outlet. https://forum.millerwelds.com/forum/welding-discussions/4750-tig-input-amperage

Vigo

Solar Addict

Im not much of a welder but it seems like the thread junped the shark talking about those integrated genset/welders. Does OP already have some other form of generator?

Generator noise correlates pretty heavily to load. Ive had a ~700w inverter generator that was VERY quiet at <300w. Currently have a ~1700w continuous inverter gen that is fairly quiet below 1000w but gets loud above that. 4k non inverter in rv is louder than the inverter gen at low lod but quieter at full load. 5k non inverter from the 80s… loud no matter what!

Point being, if you already have a generator that makes an ‘acceptable’ amount of noise at some load level, consider whether there is way to set it at that load charging into your battery bank during welding. It doesn’t have to fully power the welder, as long as your inverter and batteries can for a reasonable amount of time. What it would do is increase your ‘duty cycle’ not of the welder itself but of how much you can run it in a given period of time. This is one of the big intrinsic benefits of running off inverters and batteries. Your supply (solar/battery) doesnt have to be able to hit your peak demand, it just has to be able to hit your average demand, over time. Same concept with hybrid cars. If you dont rhink you would floor it in a hybrid car long enough to feel the performance fall off when the battery is exhausted and you are limited to the ‘instantaneous’ production of the engine, consider whether you would do that with a welder either?

But in general i am in the camp of using a generator to supplement the existing system (if your existing inverter will run the welder) rather than buying a crazy amount of additional solar/battery capacity for one specific use case that will only occur 5% of the time, if that. Now if you were planning to majorly upgrade the house system anyway and welding is just a good excuse to go big, then go for it!

Generator noise correlates pretty heavily to load. Ive had a ~700w inverter generator that was VERY quiet at <300w. Currently have a ~1700w continuous inverter gen that is fairly quiet below 1000w but gets loud above that. 4k non inverter in rv is louder than the inverter gen at low lod but quieter at full load. 5k non inverter from the 80s… loud no matter what!

Point being, if you already have a generator that makes an ‘acceptable’ amount of noise at some load level, consider whether there is way to set it at that load charging into your battery bank during welding. It doesn’t have to fully power the welder, as long as your inverter and batteries can for a reasonable amount of time. What it would do is increase your ‘duty cycle’ not of the welder itself but of how much you can run it in a given period of time. This is one of the big intrinsic benefits of running off inverters and batteries. Your supply (solar/battery) doesnt have to be able to hit your peak demand, it just has to be able to hit your average demand, over time. Same concept with hybrid cars. If you dont rhink you would floor it in a hybrid car long enough to feel the performance fall off when the battery is exhausted and you are limited to the ‘instantaneous’ production of the engine, consider whether you would do that with a welder either?

But in general i am in the camp of using a generator to supplement the existing system (if your existing inverter will run the welder) rather than buying a crazy amount of additional solar/battery capacity for one specific use case that will only occur 5% of the time, if that. Now if you were planning to majorly upgrade the house system anyway and welding is just a good excuse to go big, then go for it!

Warpspeed

Solar Wizard

Thanks for your response, the main issue here is noise, welding at 200A on ac needs a genny capable of 7000w, pretty much at full noiseIm not much of a welder but it seems like the thread junped the shark talking about those integrated genset/welders. Does OP already have some other form of generator?

Generator noise correlates pretty heavily to load. Ive had a ~700w inverter generator that was VERY quiet at <300w. Currently have a ~1700w continuous inverter gen that is fairly quiet below 1000w but gets loud above that. 4k non inverter in rv is louder than the inverter gen at low lod but quieter at full load. 5k non inverter from the 80s… loud no matter what!

Point being, if you already have a generator that makes an ‘acceptable’ amount of noise at some load level, consider whether there is way to set it at that load charging into your battery bank during welding. It doesn’t have to fully power the welder, as long as your inverter and batteries can for a reasonable amount of time. What it would do is increase your ‘duty cycle’ not of the welder itself but of how much you can run it in a given period of time. This is one of the big intrinsic benefits of running off inverters and batteries. Your supply (solar/battery) doesnt have to be able to hit your peak demand, it just has to be able to hit your average demand, over time. Same concept with hybrid cars. If you dont rhink you would floor it in a hybrid car long enough to feel the performance fall off when the battery is exhausted and you are limited to the ‘instantaneous’ production of the engine, consider whether you would do that with a welder either?

But in general i am in the camp of using a generator to supplement the existing system (if your existing inverter will run the welder) rather than buying a crazy amount of additional solar/battery capacity for one specific use case that will only occur 5% of the time, if that. Now if you were planning to majorly upgrade the house system anyway and welding is just a good excuse to go big, then go for it!

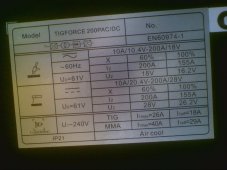

Here is the rating plate of my own 200 Amp TIG, that can also be used as a stick welder.

Its all a bit confusing, but it came with a 240v 15 amp plug, and my home made 5Kw low frequency sine wave inverter handles it easily.

Hi, yes its a little confusing because it only refers to the output power of the machine ,not the input draw from the 15A supply, im with you though, i would go higher with the hybrid inverter, maybe 7.5k, but my concern would be the battery bank, how many, what size etcThanks for your response, the main issue here is noise, welding at 200A on ac needs a genny capable of 7000w, pretty much at full noise

So that must be a 3ph welder then, im talking 240v 15A single ph.200A on TIG with AC high frequency?

I can tell you my TIG will blow a 60A breaker if you crank it up.

73powerstroke

Solar Enthusiast

He wants to argue till he hears the right answer, and doesn't want to listen. It's a waste of time trying to be helpful.I've a multitude of welders over the years. HF TIG at 200A will draw more than 26A on 240V. This isn't a buzz box with stick.

Page 10 here: https://www.lincolnelectric.com/assets/servicenavigator-public/LINCOLN3/IM895.pdf

Read here, once you start getting up in output, there should be a 100A breaker and the right size wires from it to outlet. https://forum.millerwelds.com/forum/welding-discussions/4750-tig-input-amperage

To the o.p.

No one said 200amps tig draws 200a amps at 240v, but we did say it's more than 60 amps . But he didn't read that part.

It's very tiresome when people ask for help and you give them suggestions and then they suddenly become the expert to answer the question they started with because they just didn't like the suggestions that were provided to them.

I'm done Commenting on this one obviously the original poster doesn't know much about tig welding to start with so hes going to need a lot more help than posting on this forum. I'm not trying to be rude I'm just tired of wasting my time with people that want to argue the answer when they don't have the answer.

73powerstroke

Solar Enthusiast

Lol ? ? ? ? ? ?So that must be a 3ph welder then, im talking 240v 15A single ph.

Because your 100% totaly wrong, and with 42 years as welder im very experienced, there is no 15A Domestic supply in the world capable of 60A draw, thats insane, it would pop the breakers imediatley, so go back to the drawing board and dont comment on things you dont understandHe wants to argue till he hears the right answer, and doesn't want to listen. It's a waste of time trying to be helpful.

To the o.p.

No one said 200amps tig draws 200a amps at 240v, but we did say it's more than 60 amps . But he didn't read that part.

It's very tiresome when people ask for help and you give them suggestions and then they suddenly become the expert to answer the question they started with because they just didn't like the suggestions that were provided to them.

I'm done Commenting on this one obviously the original poster doesn't know much about tig welding to start with so hes going to need a lot more help than posting on this forum. I'm not trying to be rude I'm just tired of wasting my time with people that want to argue the answer when they don't have the answer.

Zwy

Emperor Of Solar

Boswell Tigforce?Here is the rating plate of my own 200 Amp TIG, that can also be used as a stick welder.

Its all a bit confusing, but it came with a 240v 15 amp plug, and my home made 5Kw low frequency sine wave inverter handles it easily.

Maybe 1/4" at max amps and duty cycle, will take many stops and starts and by then the piece will have sucked all the heat from the weld area. I'm talking 1/2" plate or larger. Huge difference on aluminum.

Zwy

Emperor Of Solar

I don't consider what you use as a real welder for plate. Yours has it's purpose, just won't work for those jobs of thicker plate.So that must be a 3ph welder then, im talking 240v 15A single ph.

Mine is single phase. 80% duty on up to 1/2" plate.

Did I see a 35% duty cycle rating for the op's welder? Not going to weld 8 hours a day with that. Makes me think it's more of a consumer based product and probably easier to drive than its actual industrial based brethren. For what it's worth, I have one of those cheap and tiny 240v tig setups in the shed that is used to weld stainless and copper. What can I say, it works. It would be interesting to see the difference in energy consumption between some of the very old Linde welders we used to have, the newer Miller, and the very newest Millers.

But yeah, big inverter and a large battery bank. Wouldn't it be rotten if, right in the middle of welding a piece, the sun went behind the clouds and everything came to a stop.

But yeah, big inverter and a large battery bank. Wouldn't it be rotten if, right in the middle of welding a piece, the sun went behind the clouds and everything came to a stop.

Zwy

Emperor Of Solar

Lilikoi_Heavy_Industries

Solar Enthusiast

- Joined

- May 9, 2022

- Messages

- 243

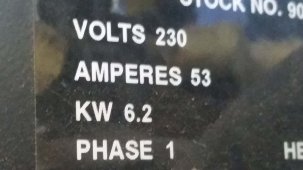

Ummm congrats?Here's the plate off my TIG, 53A max.

View attachment 105870

The original poster already clarified they can run this welder off a 7KW generator. There's not even a need to really discuss welding at that point.

Lol yeah, but then its time to go home. I have 2 tigs at home ,both 220A. They both weld 6/10mm quite happily, sometimes i preheat job depending on what it is, the tig mix function is awesome for thicker aluminium.Did I see a 35% duty cycle rating for the op's welder? Not going to weld 8 hours a day with that. Makes me think it's more of a consumer based product and probably easier to drive than its actual industrial based brethren. For what it's worth, I have one of those cheap and tiny 240v tig setups in the shed that is used to weld stainless and copper. What can I say, it works. It would be interesting to see the difference in energy consumption between some of the very old Linde welders we used to have, the newer Miller, and the very newest Millers.

But yeah, big inverter and a large battery bank. Wouldn't it be rotten if, right in the middle of welding a piece, the sun went behind the clouds and everything came to a stop.

Similar threads

- Replies

- 22

- Views

- 1K

- Replies

- 2

- Views

- 183