Pivo

New Member

- Joined

- Jan 6, 2022

- Messages

- 10

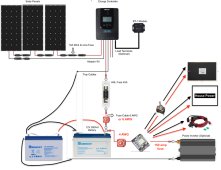

Hello all! I am in the process of building my second solar system for my cargo trailer / RV. It is all Renogy. It includes: 300w solar panels, 40a MPPT charge controller, 1000w pure sine wave inverter, and two 100ah lithium batteries. See the attached picture for the wiring configuration. Does anyone have any suggestions? I am using a Blue Sea Safety Hub 150 for my fuse box instead of a circuit breaker (it can hold 150a MIDI fuses on one side and low amp fuses on the other). I would appreciate any wisdom before I install this system in the trailer. Thanks all!!

Last edited: