You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Two cables crimped in one lug?

- Thread starter Swgraham2

- Start date

MrThisIsME

Solar Enthusiast

- Joined

- Aug 8, 2022

- Messages

- 500

Bad idea all around. Are you asking as you have 4awg wire already? Need lengths and voltage to properly recommend.

What is the point of two 4 AWG cables in a single crimp? Is it equivalent to 2 AWG?

Definitely not equivalent to 2 AWG.

Probably more like 3 AWG.

And I never use the crap leads that often come with most inverters. They are usually marginal at best, especially if aluminum.

What voltage is your inverter ?

Edit:

According to this calculator:

Two 4 AWG is equivalent to 1 AWG. Did not expect that.

Last edited:

squowse

Solar Enthusiast

- Joined

- Jan 4, 2021

- Messages

- 586

For the same cross section of copper - multiple small wires will be able to conduct more current, or the same current with less temperature rise. Greater surface area to dissipate heat.What is the point of two 4 AWG cables in a single crimp? Is it equivalent to 2 AWG? Is it overboard for my 1000W inverter?

View attachment 107121

Last edited:

Swgraham2

New Member

- Joined

- Aug 6, 2022

- Messages

- 12

My inverter is Renogy 1000W Pure Sine Wave. My battery backup is two12V lead acid batteries in parallel totaling approximately 200 AH. My inverter and cables are take-offs from a "Backroads Overland Co" camper. Apparently, the camper was displayed at trade shows and eventually sold to a customer that wanted an inverter upgrade. I bought the inverter with cables locally off a BROC rep on marketplace for a fair price.

I'm obsessed with learning solar and watching @Will Prowse videos. I can't seem to find why two cables would be crimped in one lug on the WWW.

I'm obsessed with learning solar and watching @Will Prowse videos. I can't seem to find why two cables would be crimped in one lug on the WWW.

Bud Martin

Solar Wizard

- Joined

- Aug 27, 2020

- Messages

- 4,844

BTW, if you look at Will's batteries tear down video, you will see multiple wires crimped on to one lug in a lot of batteries.

I asked the voltage of your inverter to help you see the amperage your wire might be asked to deliver.

Accounting for approximately 85% efficiency from your 1000W inverter at 12Vdc (will range from above 12 to below 12 based on your state of charge) you could easily see a 100 Ampere current draw.

This chart will help you choose an appropriate wire size after you account for length and shoot for a 3% or less Voltage drop :

www.bluesea.com

www.bluesea.com

Hope that helps.

PS. Bigger wire than calculated is never the wrong choice. It costs a bit more but can help pay for itself over time through increased efficiency. And additional safety may be priceless IMHO.

Accounting for approximately 85% efficiency from your 1000W inverter at 12Vdc (will range from above 12 to below 12 based on your state of charge) you could easily see a 100 Ampere current draw.

This chart will help you choose an appropriate wire size after you account for length and shoot for a 3% or less Voltage drop :

Part 1: Choosing the Correct Wire Size for a DC Circuit - Blue Sea Systems

Engineering high quality marine electrical components for safety, reliability and performance

Hope that helps.

PS. Bigger wire than calculated is never the wrong choice. It costs a bit more but can help pay for itself over time through increased efficiency. And additional safety may be priceless IMHO.

It is very very common to have multiple conductors in a single lug, but not recommended.

It is best to have a single insulated conductor connected to a single lug as they are designed to work in that configuration.

It is best to have a single insulated conductor connected to a single lug as they are designed to work in that configuration.

Steve_S

Offgrid Cabineer, N.E. Ontario, Canada

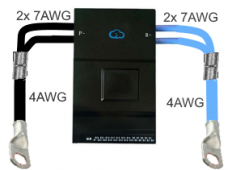

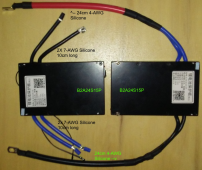

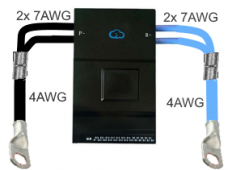

I did something similar to my BMS', there is 2 P- & 2B- which had to be extended for the boxes to set them where they were needed.

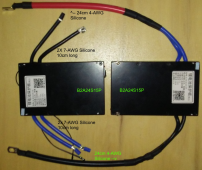

I tested them before putting them online and zero issues. Nite that the JKBMS' come with Silicone with and I used Similar Silicone but lager guage. See Below. * They did not have Blue 4-AWG so I got red, oh well. You may not the ends are different, the B- is sized to connect to the cell and the P- to the 3/8 Terminal Lug leading for the battery pack. All Crimps are done with a Hydraulic Cimper so no loosie goosey there. PS Use only Shrinkwrap with Adhesive. For the obvious potential question 2x7-AWG = 4-AWG so no current capacity is lost.

I tested them before putting them online and zero issues. Nite that the JKBMS' come with Silicone with and I used Similar Silicone but lager guage. See Below. * They did not have Blue 4-AWG so I got red, oh well. You may not the ends are different, the B- is sized to connect to the cell and the P- to the 3/8 Terminal Lug leading for the battery pack. All Crimps are done with a Hydraulic Cimper so no loosie goosey there. PS Use only Shrinkwrap with Adhesive. For the obvious potential question 2x7-AWG = 4-AWG so no current capacity is lost.

Steve_S

Offgrid Cabineer, N.E. Ontario, Canada

I decided not to edit the previous post but to add other items.. Heck, it was 03:00 when I wrote the above.

1) Nothing sticks to true Soliconized Wire, The Wrap with Glue does stick to the connector.

2) 7 AWG is extremely Butt Connectors are Extremely Hard to find & for the life of me I can't remember where I got mine, they need to have "flared" ends to get every strand in there.

3) Siliconized wire is also Very Very fine and silver in colour but you can see the copper with a magnifying glass if you look at the cut edges.

4) When using a Butt Connector, there is a centre dimple in the centre, be absolutely certain that the wire is SEATED to that dimple from both sides.

Also I will add that you really do need to use a Hydraulic Crimper to ensure Maximum Seal, there is enough room on both sides for 2 Crimps per end (should be).

1) Nothing sticks to true Soliconized Wire, The Wrap with Glue does stick to the connector.

2) 7 AWG is extremely Butt Connectors are Extremely Hard to find & for the life of me I can't remember where I got mine, they need to have "flared" ends to get every strand in there.

3) Siliconized wire is also Very Very fine and silver in colour but you can see the copper with a magnifying glass if you look at the cut edges.

4) When using a Butt Connector, there is a centre dimple in the centre, be absolutely certain that the wire is SEATED to that dimple from both sides.

Also I will add that you really do need to use a Hydraulic Crimper to ensure Maximum Seal, there is enough room on both sides for 2 Crimps per end (should be).

MrThisIsME

Solar Enthusiast

- Joined

- Aug 8, 2022

- Messages

- 500

Would like to add, a hydraulic crimper that is made the wire size you are using. Many crimpers on Amazon; the dies are for metric cable and they provide you a conversion chart to convert from mm to gauge. Not the same.Also I will add that you really do need to use a Hydraulic Crimper to ensure Maximum Seal, there is enough room on both sides for 2 Crimps per end (should be).

Steve_S

Offgrid Cabineer, N.E. Ontario, Canada

If you're feeling flush just make up new leads with 2awg wire with tinned lugs and call it a day. Don't forget a proper fuse/breaker where the lead connects to your battery/bus.

This place has really nice flexible battery cable/wire in plenty of colors, at a good price and ships fast. 5' of #2 red cable - $21:

www.ebay.com

www.ebay.com

This place has really nice flexible battery cable/wire in plenty of colors, at a good price and ships fast. 5' of #2 red cable - $21:

Security Measure

Last edited:

Steve_S

Offgrid Cabineer, N.E. Ontario, Canada

Tsk Tsk Task... The Chinese are NOT the only ones that do such things, Several EU & Even US makers do so. TUDE goes elsewhere please.If you have to have two cables. Each should have its own crimp connector and just stack them. Just because some Chinese battery manufacturer does it doesn't mean it's the correct way to do it.

BTW, it should be obvious I AM CANADIAN.

I wasn't directing my comment to you.Tsk Tsk Task... The Chinese are NOT the only ones that do such things, Several EU & Even US makers do so. TUDE goes elsewhere please.

BTW, it should be obvious I AM CANADIAN.

I spent my engineering career in ...automotive(including EV), defense, commercial....in none of the industries that I worked in were we allowed to put two conductors in a single crimp connector.

Thinking on this, it makes sense to me that putting all conductors in a single lug would be less oxidized connection points, therefore less resistance in the circuit.I've never seen any industry standard allow for multiple conductors in a single lug.

@Steve_S can you post literature or some form of evidence to support your claim that multiple conductors can safely be used in a lug that is designed for a single conductor?

I KNOW, code does not allow multiple conductors under a screw terminal not specifically designed for it, but a lug sized for the total # of strands and properly crimped would be a better solution than crimping two or three etc lugs, and placing them under a single terminal.

Similar threads

- Replies

- 3

- Views

- 220

- Replies

- 6

- Views

- 205

- Replies

- 25

- Views

- 953