It is an LC circuit. If the resonant frequency and under-damping allows, it may ring wildly. If a huge bulk capacitance, then my approximation of DC voltage applied to L alone might be OK.

In this case we are talking about an inductance of 0.3-1.0mH and a capacitance of 10-20mF - would a ratio of 10-67 qualify as 'huge'???

If you use a transistor to pull an inductor up to +24VDC, current starts ramping up. When transistor turns off, inductor snaps to negative infinite volts. Or to the point of breaking down transistor. Parasitic capacitance (of inductor windings or circuit) may slow the rise (negative edge) time and limit voltage somewhat.

This is the part I’m still struggling with. Current is flowing through inductor when transistor turns off. That same current continues to flow when transistor turns off, meaning voltage between output and input continues to increase.

If there is no reservoir of charge at the inductor input, I see how that could translate to negative infinite volts, but if there is any capacitance at the inductor input, voltage decrease will be much slower.

And if capacitance at inductor input equals capacitance at inductor output (what we’ve been calling the Input capacitance), the rate of voltage decrease at the inductor input will equal rate of continued voltage increase at the inductor output (both also dropping at a rate driven by average current output.

Of course, that added capacitance at the PWM output will bring back all of the high-harmonic heat that jimbob32 was originally motivated to avoid when he added the inductor in the first place, but since that added capacitor does not need to be the same size as the inout capacitance, it still offers an option to limit negative voltage swing during the OFF phase, right?

A reverse-biased diode across inductor while applying +24V will clip that negative infinity down to about -0.7V (not above +24V). Inductor will drive current through it for a while. That's the basic operation of a Buck regulator. A MOSFET in place of (or in parallel with) diode reduces dissipation and wasted power.

I understand that but feel like there should be a way to limit negative voltage swing so that it is at most done multiplier of positive voltage swing. From a starting voltage of 25V, the same computation you performed earlier means a ~100uH inductor will have a maximum of 8A flowing within the 20uS ON period. That should mean the maximum current that can be driving negative voltage swing at the beginning of OFF period is 8A + 10A = 18A.

18A for a full 20uS is 360uCoulomb which would drive a negative swing of only -36mV to 23.964V on a 10,000uF capacitor at inductor input.

If that added capacitance were dropped to only 100uF, wouldn’t that translate to worst-case negative voltage swing by the end of the OFF period to less than -3.6V to inductor input voltage that can’t be lower than 20.4V?

If what you have is a solenoid or relay you want to turn off fast, the freewheeling diode may keep current conducting too long. A resistor and diode in series is a snubber, and voltage is limited to I x R, can be sized to remain within transistor's voltage handling ability.

I don’t know protections a PWM may have to prevent negative voltage on the output, but I’d rather find a solution that keeps all voltages between 0-57.6VDC and does not need to rely on diodes or reverse-voltage protection.

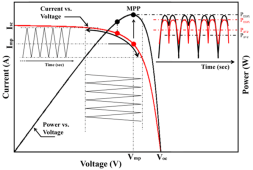

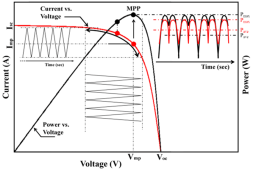

The key epiphany I learned from you is that inductance translates to a maximum current change within an interval of time.

That means an inductor can limit current increase or decrease from a square wave and can maintain a known current swing around an average DC current.

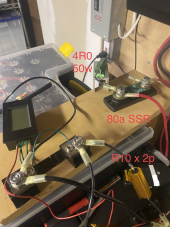

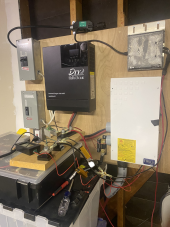

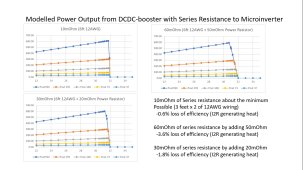

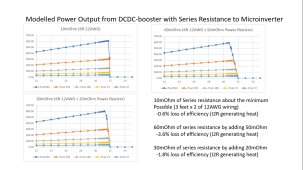

I’m not going to bother with Spice yet, but I might try working op a piece wise-linear spreadsheet-based model such as the one I used to convince myself that 50-100mOhm between a battery and a Microinverter was needed to make the MPPT function more easily.

I’m going to try:

-Switched idealized current source (floating output when OFF)

-into smaller output capacitance

-into ~100uH inductor into 20,000uF input capacitance

-into idealized voltage source (MPPT).

I’ll report back when I have results to share.

The orthogonal L R impedances might be useful for calculating current through transformer with secondary open, especially in saturation where inductive reactance is reduced. Conjugate impedance matching involves adding a "C" which resonates with "L" at operating frequency, so series LC presents zero ohm impedance. That leaves just "R", with lower impedance magnitude so higher current and power than what SQRT(R^2 + XL^2) let through.

At elevated frequencies, "skin effect" means resistive component of inductor is not same as DC resistance.

Bunch of EE stuff, some of which I occasionally apply. Mostly, I used Ohm's Law and Geometry.

I appreciate all if this EE stuff but am hoping I can skate around it.

One question I do have for you, though:

If we’ve determined that a ~100uH inductor will protect a capacitor from seeing more than 8A of ripple current over a period of 20uS, doesn’t that mean that the same inductor would protect the same capacitance from the same >8A ripple current from a switched current source such as one of the cheap DCDC boosters (at least for current ripple at 25kHz or higher?

The inductor needs to be sized to handle the full DC current (8.3-10A) but since there is no ‘OFF’ period with a current source, when the Microinverter moves from Vmp to deliver target power @ programmed current (8.3A for 250W @ 30VDC) to much lower power and current at some voltage beyond prigramned maximum voltage of 30V, the inductor will act to limit both the rate f current increase as well as the rate of current decrease.

But since the timescale or inverters switching is 16.7ms (60Hz) versus the 40uS (25kHz) switching rate we’ve been talking about for PWM controllers, it should be a non-issue, shouldn’t it.

Can you see any reason an inductor should not be added inline between a DCDC booster and a Microinverter to protect the input caps of the Microinverter from high-frequency ripple current that might emit from the switched DCDC booster?

"If we assume inductor current can drop to 0A before the end of OFF time"

That is "discontinuous conduction mode". If inductor is big enough for a given load, you get a DC current with sawtooth ripple riding on it. There are various SMPS modes of operation, producing various noise that may matter in sensitive applications.

Noise does not matter in the case of a Microinverter being powered by a PWM controller, merely ripple current, so I think it is precisely that ‘DC current with sawtooth ripple riding on it’ that we are looking for.

Hopefully with your help I’m getting closer…

I think you've got the first-order idea, which is about what I've got. I did go through the different switching regulator architectures in a college class. Someone who specializes in it would be more on top of the analysis. I've bounced around from microprocessor design to missiles to multi-chip modules to atomic mass spectrometers to vacuum applications involving electrons, and EMI/EMC. It keeps me confused and I have to dig up examples of how to do things.

Your understanding goes leagues beyond mine and I appreciate your efforts to educate me. Between the evolving theory and the incoming experimental results, I’m increasingly confident this nut is on it’s way to being cracked…

.