You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

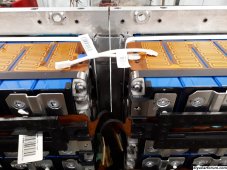

What 282 kWh CATL LFP look like

- Thread starter yabert

- Start date

yabert

Solar Enthusiast

OMG.... this idea of carbide metal saw do is way in my mind ?Well then, saw it.

Why not?I'm not a huge fan of BMS in parallel, but I trust physical busbars in parallel.

yabert

Solar Enthusiast

Reliability and cost.Why not?

It's not a hard no for this project, but generally I will prefer the reliability and the low cost of a busbar + screws or welds instead of the potentially problematic BMS (thousand parts/cost $$) + wires + connectors.

yabert

Solar Enthusiast

Of course. I'm not arguing against BMS here, I'm arguing 6 BMS vs 1 BMS.Um You need both bus bars AND BMS. Busbars to carry the current, BMS to protect the cells against over/under voltage. Running no BMS is strongly discouraged.

yabert

Solar Enthusiast

What BMS can handle 96 cells in a 16S6P 48V configuration? I suppose some commercial grade stuff somewhere does.Of course. I'm not arguing against BMS here, I'm arguing 6 BMS vs 1 BMS.

yabert

Solar Enthusiast

That exactly the point. It will not handle 96 cells, but only 16 cells because I plan take six 228Ah cells and create one 1368Ah cell.What BMS can handle 96 cells in a 16S6P 48V configuration? I suppose some commercial grade stuff somewhere does.

labeeman

Solar Enthusiast

I have 20 BMS in parallel what is the problem with that each one only has to handle 1/20 of the load or charge?Of course. I'm not arguing against BMS here, I'm arguing 6 BMS vs 1 BMS.

A standard circular saw is a bit faster and may gum up the blade or wear out faster even on aluminum. Aluminum circular saw blades are cheaper than a metal cutting tool though.I'm clearly not a fan to destroy this awesome piece of engineering... with a circular saw, but wow, this aluminum was so easy to cut.

It seem like I could try to cut this aluminum chill plate in six to have nice 11.7 kWh 16S packs ?

View attachment 177343

yabert

Solar Enthusiast

Nothing wrong with it. I simply prefer the reliability of non active components (busbars vs Fets, drivers, current measurement, etc).I have 20 BMS in parallel what is the problem with that each one only has to handle 1/20 of the load or charge?

labeeman

Solar Enthusiast

use a little lubricant like WD40 or kerosine on aluminumA standard circular saw is a bit faster and may gum up the blade or wear out faster even on aluminum. Aluminum circular saw blades are cheaper than a metal cutting tool though.

labeeman

Solar Enthusiast

I know of no BMS with nonactive components.Nothing wrong with it. I simply prefer the reliability of non active components (busbars vs Fets, drivers, current measurement, etc).

yabert

Solar Enthusiast

Playing with cells/BMS since 15 years now, I've seen way to horror stories of BMS who destruc cells.I know of no BMS with nonactive components.

So, to me, minimum of BMS and I plan to add a monitor device who verified the job of the BMS is right.

yabert

Solar Enthusiast

Yes, well 16S 6P. One big cells. Exactly the same as when LG chem, CATL, SK innovation or car manufacturers decide to connect cells in parallel in EV battery packs.So wait, you plan on doing 6S16P? 6 cells in parallel to each other, each set of 6 on a single BMS channel?

Not only me, but friends, coworkers, members on forums.What BMS have you used over the years that were so bad?

It's not always related to the electronics stuff, some time is the programing/control and regularly it's user.

Still, to me:

BMS = Extra cost, more consumption, more prone to failure, extra wires/connections.

Busbar = Reliability at low cost.

Last edited:

yabert

Solar Enthusiast

Well I guess the biggest difference is you're using true automotive grade cells that have already been matched. I wouldn't attempt that with the run of the mill so called "A" grade we normally get, partly because even if they were premium cells the odds of getting perfectly matched cells are next to nil and those variances may play out on undesirable ways with multiple cells in parallel.Yes, well 16S 6P. One big cells. Exactly the same as when LG chem, CATL, SK innovation or manufacturers decide to connect cells in parallel in EV battery packs.

Not only me, but friends, coworkers, members on forums.

It's not always related to the electronics stuff, some time is the programing/control and regularly it's user.

Still, to me:

BMS = Extra cost, more consumption, more prone to failure, extra wires/connections.

Busbar = Reliability at low cost.

Though flipside is, if you have multiple packs each with its own BMS and one BMS fails, you're only down one battery and can still operate off the rest. If all your cells rely on only one BMS and it fails, well now you're out everything (unless you have a spare BMS just sitting on standby).

You’ll be the expert soon. ?First test with the saw done.

I'm amazed how well it cut in this chill plate

The fact that chill plate is almost empty to allow the cooling to flow result that all the wall have small thickness.

The other axe will be way more tricky.View attachment 177435

Similar threads

- Replies

- 11

- Views

- 479

- Replies

- 21

- Views

- 1K

- Replies

- 5

- Views

- 446

- Replies

- 2

- Views

- 204