OffGridForGood

Catch, make or grow everything you can.

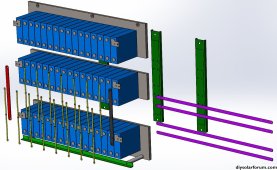

I am wondering if you could have just stood the pack up-right instead of cutting. Like a Tesla power wall set up, so it doesn't take up much floor space.

Can those cells be that orientation? Then: Cut the bus bars that you need to and make new ones to create the 16s-6p arrangement you wanted.

If I start driving tomorrow early I can be in Quebec City by Tuesday afternoon to pick up two of those original (un-cut) packs and get them out of your way!

From the dimensions, two packs will fit side by side in a truck box, 2,000 lbs is fine for my 1-ton for the trip home!

Can those cells be that orientation? Then: Cut the bus bars that you need to and make new ones to create the 16s-6p arrangement you wanted.

If I start driving tomorrow early I can be in Quebec City by Tuesday afternoon to pick up two of those original (un-cut) packs and get them out of your way!

From the dimensions, two packs will fit side by side in a truck box, 2,000 lbs is fine for my 1-ton for the trip home!