yabert

Solar Enthusiast

I was really lucky and was able to bought new old stock of four 70.5 kWh CATL batteries built to be use on electric truck (class 6-7... you know, big truck, but not semi).

I didn't really know what was inside at the time of purchase except they are 70.5 kWh, 96S (309V nominal) and 228Ah cells build in 2020. My main goal was to have one 24V or 48V 70.5 kWh battery in our house and sell the other 211 kWh.

I received the 4 batteries few days ago and I uncrated one to see how it build.

I measure the voltage between one terminal and the disconnected MSD, 315V, good.

I removed the lid and fu*k, the cells terminals are welds and not bolted

Few seconds later, aaaaaaah! they are weld in pack of 16S, nice ?

So 6 packs of 16S 228Ah with 6 BMS ''slave'' (no fets, no contactors to cut power).

Awesome, I will be able to sell many 48V 11.7 kWh 170 lbs batteries at good price... well, not really.

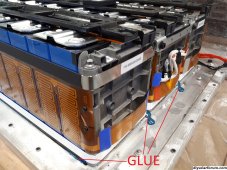

As battery designer myself, I was intrigued by the manner those prismatic cells was hold on the big aluminum chill plate. Kind of strapped support? Tie down with bolts?

No, they are glue/bond on the chill plate and look to be impossible to separate except by cutting the chill plate.

Well, it seem like I could fairly easily cut the chill plate in two and have 35 kWh batteries, but it almost certainly the smallest battery I can do with this. The main problem is evidently the weight as 35 kWh is 450 lbs. Not so easy to move around.

There is also the size of 70 kWh, 2050×640×240mm (81 x 25 x 9.5''). Not really small.

Anyhow, those batteries seem really well build with compression straps and casted end plates, rubicond flexible PCB to reach BMS, wire bond fused between terminals and PCB, heat pads at each side of the cells, huge busbars, everything look good quality.

I didn't really know what was inside at the time of purchase except they are 70.5 kWh, 96S (309V nominal) and 228Ah cells build in 2020. My main goal was to have one 24V or 48V 70.5 kWh battery in our house and sell the other 211 kWh.

I received the 4 batteries few days ago and I uncrated one to see how it build.

I measure the voltage between one terminal and the disconnected MSD, 315V, good.

I removed the lid and fu*k, the cells terminals are welds and not bolted

Few seconds later, aaaaaaah! they are weld in pack of 16S, nice ?

So 6 packs of 16S 228Ah with 6 BMS ''slave'' (no fets, no contactors to cut power).

Awesome, I will be able to sell many 48V 11.7 kWh 170 lbs batteries at good price... well, not really.

As battery designer myself, I was intrigued by the manner those prismatic cells was hold on the big aluminum chill plate. Kind of strapped support? Tie down with bolts?

No, they are glue/bond on the chill plate and look to be impossible to separate except by cutting the chill plate.

Well, it seem like I could fairly easily cut the chill plate in two and have 35 kWh batteries, but it almost certainly the smallest battery I can do with this. The main problem is evidently the weight as 35 kWh is 450 lbs. Not so easy to move around.

There is also the size of 70 kWh, 2050×640×240mm (81 x 25 x 9.5''). Not really small.

Anyhow, those batteries seem really well build with compression straps and casted end plates, rubicond flexible PCB to reach BMS, wire bond fused between terminals and PCB, heat pads at each side of the cells, huge busbars, everything look good quality.

Attachments

Last edited: