myersfamilyhome

New Member

- Joined

- Feb 9, 2021

- Messages

- 140

How does one handle properly wiring large gauge PV wire to an CC that has smaller connections?

Scenario :

6x Panels @ 37.07v/13.79a

Distance from Panels to CC: 100ft

EG4 6000EX : PV Connection unspecified (assuming <= 8AWG)

* Not provided in the manual

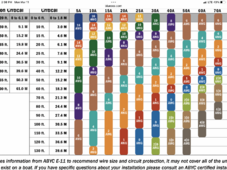

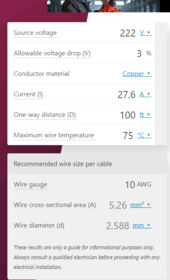

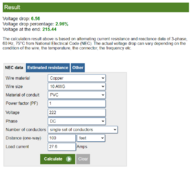

At this distance, running 15a at 100' require 2AWG. With this in mind and with the CC connections being smaller, how do you properly hookup? Do I run the 2AWG to a disconnect right before the CC and then stepdown the wire to the largest acceptable AWG that will fit in the CC for the remaining few feet?

Scenario :

6x Panels @ 37.07v/13.79a

Distance from Panels to CC: 100ft

EG4 6000EX : PV Connection unspecified (assuming <= 8AWG)

* Not provided in the manual

At this distance, running 15a at 100' require 2AWG. With this in mind and with the CC connections being smaller, how do you properly hookup? Do I run the 2AWG to a disconnect right before the CC and then stepdown the wire to the largest acceptable AWG that will fit in the CC for the remaining few feet?