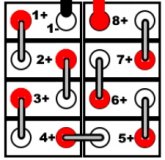

Technically Screws or Nuts, threaded posts with nuts all do the same thing. They are intended to connect the Bus Bars to the face of the contacts, the "threaded" part is not what carries the lions share of the voltage / amperage. The supplied bus bars are long enough to link cells together in series BUT not if you want to cross over... See image attached, when I mean in series is from one cell to the next (1+ & 2-) but going across from (4+ to 5-) Cell the bus bars are too short my 10mm if mem serves.

View attachment 14373

You are better off setting up / aligning the cells and binding them and then installing the busbars loose fit till all lined up and then tighten then down. Of course balancing leads etc all installed too. BE AWARE OF THREAD DEPTH ! Before doing anything else, without busbars, put a screw in and hand tighten it down to the bottom and see how much thread is left, next put two busbars on there and d the same (by hand only) and if it tightens up nicely your good to go. Ultimately you NEVER want that thread to bottom out in the cell, it could break through ad that would be Very BAD ! The best way to ensure that the thread isn't too deep is pre-checking it by hand. The "general / generic" rule is tighten the screw down by hand and then back it off at least 1 full turn and THAT is the tightest point you can safely go. With the screws supplied, two busbars & one washer ended up at just the right height. I was supplied with Stainless Steel Screws and Copper Busbars from Xuba. While I did get that material from Xuba, I elected to use COPPER C110 FLAT BAR ASTM-B133 0.125" x 0.750" to make my own busbars. The LONGER Bars to cross between 4+ & 5- are 4.250" long. (just looked up the quote) NB: I drilled the holes in my busbars to 5/16 so they are as snug as I can get while leaving a wee bit of jiggle room for adjustment.

Hope that helps, good luck.