It looks like it's on the opposite side from the terminals ... here's a picture from the web page.

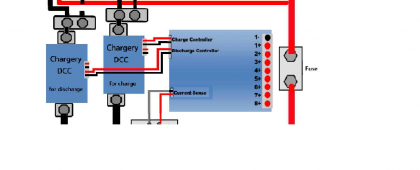

They are bi-directional, so the connections shouldn't matter .... but I attached a common a separate port diagram from the web page.

The other thing to be aware of ... if you are switching inverter power ... is that the pre-charge circuit only works when the DCC is manually powered up ... it doesn't work if the BMS turns it off and back on. I hope they fix that one of these days.

If you search on Youtube there is a nice video where the guy used a Chargery delay board to automate a pre-charge circuit.

View attachment 47946View attachment 47947View attachment 47948