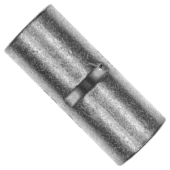

Yes, I put BOTH 7-AWG into a 4-AWG Butt Connector that has 13mm (1/2") on BOTH Sides for crimping.

LINK HERE: (See the Spec Sheet for proper detail)

Order today, ships today. 34323 – Terminal Butt Splice, Inline, Individual Openings Connector Crimp 4 AWG from TE Connectivity AMP Connectors. Pricing and Availability on millions of electronic components from Digi-Key Electronics.

www.digikey.ca

Sorry I only have a ph

View attachment 96546oto with it Shrink Wrapped already.

I now have 3 running and there is absolutely no issues whatsoever.

In Fact, after a few "Trials & Tribulations" with the JK Software (What a PITA) and doing the 9V Kick Start I am quite pleased with the results.

Using the enjpower-bms-3.7.4.88 software which WORKS

tHE 极空BMS_4.6.5.apk PROVIDED ONLINE fails to Install. Apparently not quite compatible.

Thank Goodness for

@upnorthandpersonal and his diligent help !

Awesome Stuff....

Also an interesting BTW/FYI...

I did the two EV-Cell Packs (the 175's) which were always "cranky" and now they charge, nicely and keep to a tight cell delta from 3.425 down.

I setup Balancing to start @ 3.37V as I am only charging the batteries "Bulk/Absorb" to 3.4375Vpc and Floating at 3.425Vpc so I am never hard pushing above the working range.

Hope it Helps, Good Luck