robbob2112

Doing more research, mosty harmless

So, don't leave us hanging. What did the vendor say?

Haven't talked to them, I can't wait on hold for an hour.So, don't leave us hanging. What did the vendor say?

Sent a message thru the Signature Solar support webpage Tuesday. This way I won't have to sit on hold. I have not heard any acknowledgement they have read the message and no response. This is a test of their support, in previous videos I related my experience with tech support and how bad it was so I guess I'll be making another documentary that possibly things have not improved there.So, don't leave us hanging. What did the vendor say?

Thanks for the tag! How can I help? This email was sent to us May 8th at 10:27am and we responded, May 9th 10:11am.. Our email team aims to respond to each email within a maximum of 24 hours but for a faster response, you can call 9034412090 to speak with a technician. Our wait times are typically around a minute long. In the past they were much longer but we have increased staff and this has improved wait times exponentiallyYo, @SignatureSolarJess - you have work to do

You spoiled the fun.Yo, @SignatureSolarJess - you have work to do

You spoiled the fun.

I like to test their system and report on it. Next time, I'm not posting about it.

A.K.A Funsucker LOLThat is me... Super spoil sport to the rescue. Spoiling sourpuss who rather be unhappy everywhere.

It is test with SS support. How long or bad can they screw up?That is me... Super spoil sport to the rescue. Spoiling sourpuss who rather be unhappy everywhere.

It is test with SS support. How long or bad can they screw up?

One of my most viewed videos was about the failure on their end regarding tech support.

I'm not going to sugarcoat things but I will give credit if it is due. Marcus took care of me when I first installed the charge controllers and there was a F01 code setting. Regular tech support was just horrible. https://diysolarforum.com/threads/e...mppt100-48hv-sets-code-f01.68669/#post-867926

I can't say enough good things about the charge controllers, they have worked flawlessly since the firmware update. These do exactly what the units were designed to do. It is the other half of the equation that was lacking.

I can't give an honest opinion if things don't play out for the average person that buys from there and needs support.

They watch videos to learn from others. Some of the subscribers are from here but some are just searching and researching.The average person doesn't do DIY, they hire it out. The above average person (or the cheap person) does DIY and is on here to learn about how to do things

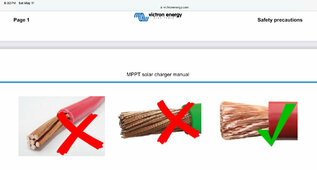

I'm confused. It looks like all the connections in this video are screw down terminals, so didn't he do the right thing by using ferrules? If you use a screwdriver to set the wire, that's a screw down terminal, isn't it?Victron specifically says not to use ferrules (except on screw down terminals). You may cause increased resistance. The terminals for both Victron equipment (besides the connections that are for lugs) and IMO are clamping style terminals

These appear to all be clamp type connections.I'm confused. It looks like all the connections in this video are screw down terminals, so didn't he do the right thing by using ferrules? If you use a screwdriver to set the wire, that's a screw down terminal, isn't it?

Cables move under surge loads sometime minute’ movement sometimes noticable. Why there are cable forming and tie downs on big equipment ….. 1600/24 cable moves on locomotives and must be restrained so it doesn’t chaff and short.Thanks a lot for this video.

After watching it I went and checked the terminals on my inverter and 2 of them were looser than they should be. Definitely they seem to loosen over time. Will have to keep an eye on that. Again thank you.

Wow. @ZwyYou are using 10ga wire for pv over a very long run?

It will be most obvious at connections where resistance is higher. Why we ran straight runs and no splices - connections on aircraft - aviation - (edit) other breaker) source to load.Wow. @Zwy

Could what @D71 said be related to your problem?

I was originally planning to do 100 yard runs to my panels and was told I would need 8AWG to keep voltage loss to within acceptable levels at that distance, and I'm running lower voltage than you are. Long strings of 8AWG was too expensive I abandoned the idea.

But if you're running 10AWG over long distances at pretty high voltage. Maybe it's causing wire heating issues for you?

It will be most obvious at connections where resistance is higher. Why we ran straight runs and no splices - connections on aircraft - aviation - (edit) other breaker) source to load.

My findings others may differ the pressure breaks weakest link. Why water and electricity are used to describe events…to ppl learning. Drinking out of warm garden hose cooked by sun. The initial water is warm if hose is in direct sun light. Most ppl never drink out of water hose but drink from pex all the time.

I had a&p license stopped working on them went back to college. Returned license to faa. Ppl with helicopters don’t want to do proper maintenance. All chip detectors and fire detection circuit were straight run …. No connecters repairs on helicopters .. many radio nav were same….j600 section all tiny wire straight runs.When in the Navy I worked on Lockhead ES3-A aircraft. It was originally a submarine hunter that was converted to electronics warfare.

In that plane the generators on the engines feed the main load centers. Those all went through breakers. From the breakers they went to cannon plugs with anywhere from 2 pins to several hundred. That passed it through the bulkhead to another part of the plane. From there it would feed port and starboard electronics bays internal and external. Also external port and starboard bays at the tail. Also wiring up in the tail to run the hydraulic actuators to fold the tail and the radio antenna. In each bay there was a bulkhead connection to the racks. Then cannon plugs to the equipment.

All that said any wire on the plane would pass through anywhere from 4 to 12 connections.

We had 30day, 90day, 120day, 240day inspection cycles. During the 240day we basically disassembled the plane and took everything apart down to the last bolt and screw. Then we put it all back together with clean connection and thin film preservatives on every connection, screw and bolt.

Those airplanes flew from 1972 through 1996.

My point being cleaned and inspected makes it safe so long as it is maintained.

For battery banks it only makes sense to use as few or as many connections as needed to do it right.

I had a&p license stopped working on them went back to college. Returned license to faa. Ppl with helicopters don’t want to do proper maintenance. All chip detectors and fire detection circuit were straight run …. No connecters repairs on helicopters .. many radio nav were same….j600 section all tiny wire straight runs.

Like stated some.

Consistence is my failure i left out specifics in next post.

View attachment 214732

We also secured every cannon plug with .020 lock wire. Somethings for safety had breakable .020 copper safety wire on other items. Before that there was tye strings as well as spring cammed twist locks that secured with spring tensions for connection.

Amphenol Plug Are common and lockwired in aviation You are correct there are lot connection for some circuits there were also tb about repairs and allowances.

Some ppl argued the safety wire pliers damaged the lock wire so twisted the required twist per inch by hand used duck bills for last tight twist.I still have my set of safety wire pliers from my kit and still use them from time to time. A lot of the larger ones had a locking feature when turning. But the ones in hard to inspect locations were all safety wired.

Some ppl argued the safety wire pliers damaged the lock wire so twisted the required twist per inch by hand used duck bills for last tight twist.Young guys put on beautiful lockwire and get mad when I cut it say do over….they put neutral or negative safety wire where it wasn’t allowed.

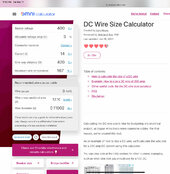

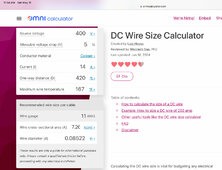

Vmp of my panels 41.84V. Imp is 12.67A. 8S comes to Vmp of 335V.Wow. @Zwy

Could what @D71 said be related to your problem?

I was originally planning to do 100 yard runs to my panels and was told I would need 8AWG to keep voltage loss to within acceptable levels at that distance, and I'm running lower voltage than you are. Long strings of 8AWG was too expensive I abandoned the idea.

But if you're running 10AWG over long distances at pretty high voltage. Maybe it's causing wire heating issues for you?

I have noticed that some battery wire has super fine strands. I'm using 2 AWG wire and the super fine strands didn't work very good with the clamp type terminals with or without ferrules. The welding cable sold by Temco isn't so fine and works better in the clamp type terminals without ferrules.Vmp of my panels 41.84V. Imp is 12.67A. 8S comes to Vmp of 335V.

That is at peak sun and at test conditions of 25°C. Inputting the data into the Southwire calculator, the voltage drop is 3.26% from the resistance of the wire. In my video you will see 300V on the display, the panels were in the sun all day and the panel temp was over 25°C so there will be some loss of voltage. Add that with the lower sun angle after 4pm plus the sun will be almost heading behind the array pointed due south as we get closer to summer solstice.

String voltage should be as high as possible with VOC at lowest ambient temp calculated to stay under the VOC rating of the SCC. As I have 16 panels on the array, the 8S configuration makes the most sense.

Voltage drop on PV is just a loss. I would be more concerned about power loss with higher amperage. Running 12.67A at peak sun with as high of a string voltage as possible is the best choice as power loss runs at a factor of I^2R = W. Hedges covers this in this post.

If I was running parallel strings where the amps would double, then I would be concerned with wire heating resulting in power loss. At 12.67A at peak sun, it is not a concern with running 10AWG in a single string.

The failure was at the connection point. Each connection will have resistance and that resistance generates heat. The higher resistance could have been on my connection or the manufacturer connection. One thing that will occur when the new SCC comes is I will remove the top cover and check the manufacturer connections. I found some connections in the other SCC that I was able to tighten, every connection I had made was still tight. That doesn't mean I did not miss one at the initial install but I always double check my work. I would have to miss it twice. I don't see the odds of that happening. Another possible factor is the use of the ferrules, I will be removing ferrules on all the clamp type terminals.