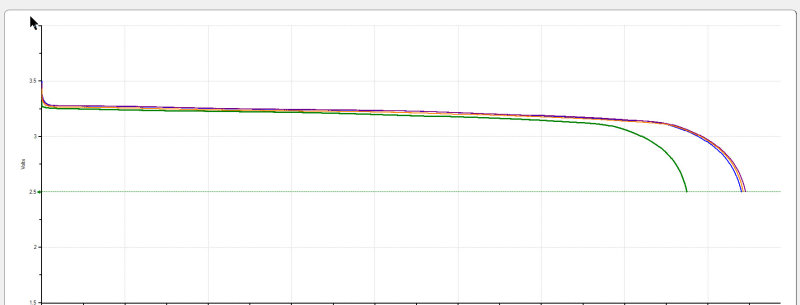

So, I have 32 cells that have been in operation for two years now. I charge at 50A+ regularly in summer per pack, and my pack often sits full during this time. I tend to go to 3.5V per cell, but don't absorb there. In winter, I take them down close to empty, but not below 2.9V. Summer and winter patterns are very different. In summer, my discharge current can be close to my inverter max output: 50A per pack. After last winter, I checked the first cycle where they would go to 100% state of charge again after many months. All cells are perfectly in balance and there were no runners.

I don't exactly pamper my cells. They can sit in the cold many times where they are discharging (not charging), they never get too hot though. I've had no issues in two years. I'm now entering year three with these, and am about to add another 32 cells - which had a side effect of lowering the charge/discharge current per pack as well.