Unfortunately I didn't read through all 9 pages to see where this has all gone, but to give you some added empathy I also had to go through some of the steps you're having to do because of inspection, all the while being jealous of the other installs where some of the things I feel give no added safety in the first place could be skipped.

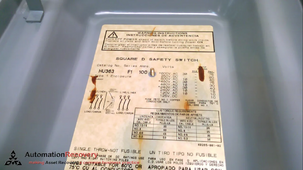

View attachment 161930

My local inspector also made me do some things that I'm 80% weren't needed in the latest version of code but weren't worth me fighting, such as using rigid conduit on my underground sections and not allowing me to run my 48V cables inside the raceway with my AC runs, but still requiring it to be in metallic. That liquid tight is metallic. But yes 100% of my high voltages lines are in metal 100% of the time after leaving the array.