silverstone

Solar Enthusiast

- Joined

- May 3, 2022

- Messages

- 1,041

I installed all the solar panels on my roof by following the advice of the guy that sold me the mounting system. Should never trust a sales person  .

.

He told me that here (in Denmark) it's not required (by law) to ground a Solar Installation.

As such now, all of the panels and Rails are floating (not grounded).

After talking with a experienced engineer, he advises to have them grounded. Not sure how much it would help in case of lighting (6mm2 would evaporate quite fast ...), but at least to detect earth faults in a string etc (would register as a low insulation resistance value, thus causing the inverter to trip).

The simplest would be to just ground the edges of the mounting rails, but that's probably not a good connection at all. The extensions between rails are not really meant for an electrical connection. Also because Aluminium very easily oxidizes, and we didn't "scrub" it before installing (was supposed to be just a mechanical connection).

The better and proper approach would be to ground every frame individually. But I'm not really a squirrel so going on a pitched roof is very uncomfortable for me at the very least. Even more now that it's full with solar panels ....

Plus I'm not really sure how to ground them properly, especially in terms of galvanic corrosion.

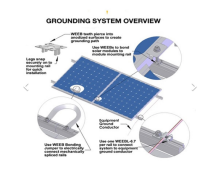

The Installation Manual of my Panel reccomends using Copper or Copper Alloy wire, together with some TE Connectivity SOLARLOK Grounding Clips (currently not in stock anywhere, in metric units M6/M8 I would assume, only 8/32'' or similar are in stock):

So I'm left with 2 choices really:

- Aluminium Wire: Smallest I could buy is 1G50 mm2. Plus Aluminium Lugs. Corrosion prevention/protection paste when crimping and screwing to the frame of the panel.

- Copper wire: probably 1G6mm2 due to cost. Plus Aluminium/Copper (bimetallic) lugs which cost a fortune.

For some reason my installation manual (in chenglish) reccomends COPPER wire DIRECTLY on an Anodized ALUMINUM frame. And the Solarlok Grounding Clip is also listed as some Copper alloy. And the process of "properly attaching" the ground connection is to use a toothed washer to "scrap away" the anodization and oxide most likely ...

What is going on here ? Shoudldn't there be a need for bimetallic lugs or just use aluminium all the way until a small box with terminals able to accept Cu/Al ? And from there just go down to the Earth rod (galvanized steel typically) ?

Thanks for your insights .

.

He told me that here (in Denmark) it's not required (by law) to ground a Solar Installation.

As such now, all of the panels and Rails are floating (not grounded).

After talking with a experienced engineer, he advises to have them grounded. Not sure how much it would help in case of lighting (6mm2 would evaporate quite fast ...), but at least to detect earth faults in a string etc (would register as a low insulation resistance value, thus causing the inverter to trip).

The simplest would be to just ground the edges of the mounting rails, but that's probably not a good connection at all. The extensions between rails are not really meant for an electrical connection. Also because Aluminium very easily oxidizes, and we didn't "scrub" it before installing (was supposed to be just a mechanical connection).

The better and proper approach would be to ground every frame individually. But I'm not really a squirrel so going on a pitched roof is very uncomfortable for me at the very least. Even more now that it's full with solar panels ....

Plus I'm not really sure how to ground them properly, especially in terms of galvanic corrosion.

The Installation Manual of my Panel reccomends using Copper or Copper Alloy wire, together with some TE Connectivity SOLARLOK Grounding Clips (currently not in stock anywhere, in metric units M6/M8 I would assume, only 8/32'' or similar are in stock):

So I'm left with 2 choices really:

- Aluminium Wire: Smallest I could buy is 1G50 mm2. Plus Aluminium Lugs. Corrosion prevention/protection paste when crimping and screwing to the frame of the panel.

- Copper wire: probably 1G6mm2 due to cost. Plus Aluminium/Copper (bimetallic) lugs which cost a fortune.

For some reason my installation manual (in chenglish) reccomends COPPER wire DIRECTLY on an Anodized ALUMINUM frame. And the Solarlok Grounding Clip is also listed as some Copper alloy. And the process of "properly attaching" the ground connection is to use a toothed washer to "scrap away" the anodization and oxide most likely ...

What is going on here ? Shoudldn't there be a need for bimetallic lugs or just use aluminium all the way until a small box with terminals able to accept Cu/Al ? And from there just go down to the Earth rod (galvanized steel typically) ?

Thanks for your insights