"you mentioned aiming for 12-15 so what is your thoughts about that?"

The trip home made me realize (I think I mentioned earlier) about how much running under power I'll actually do. On top of that, it's entirely possible to push into an adverse current for hours on end. So given then, I decided I wanted to be able to push hard, so I went from thinking 10hp would be ok (1kw:3hp) to wanting to be closer to 1:2 instead. To get that in a 48v package, 10kw/motor seems to be max. 2x 10kw would for sure give me the oomph I need when I need it, and would be overkill really. However, the best motor option I've found so far is 5 or 10kw, so 2x 10kw is the top choice atm.

"Or are you worried that the heat in the motor/controller area will be so hot that it will only push hot air around"

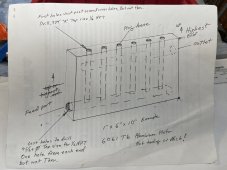

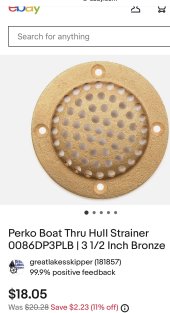

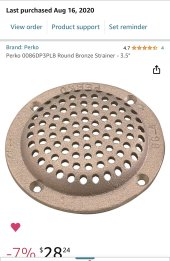

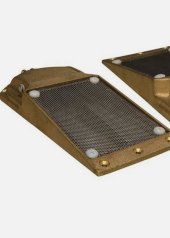

Exactly. Knowing now that motoring for 8h straight is entirely possible, that's a lot of time for heat to build up in the engine bay. I know I can vent the engine bay, and maybe that would be enough to do it. However, I already have the 3/4" through-hull/seacock and heat exchanger, so might as well use it. Should be less noisy, not having a pair of squirrel cage fans running in the engine bay as often.

If I understand it correctly the Digital Mermaid also gets allot of help in her build by her cat/s. Before I decided on building in Aluminum I did allot of research and all other materials scared me in one way or another (either from a maintenance effort point of view, or just unknowns I could not 100% control such as osmosis etc.). The curves and soft lines you can achieve with wood/glass is obviously a huge advantage but luckily I have personally always favored practicality over aesthetics so no loss on my side in that area

Wow - A 65’x14’ or 70’x16’ house boat of that style, that is what I call a house boat!! And as you say, no lack of space to put your solar panels!! Go for it!!