Bluedog225

Texas

- Joined

- Nov 18, 2019

- Messages

- 3,053

There is some deal with little fittings costing a fortune. Home Depot is charging about a buck a washer. It’s weird.

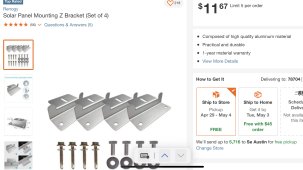

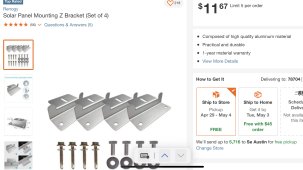

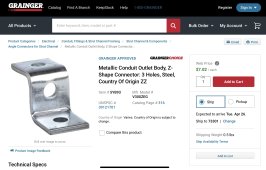

What I need are a bunch of Z shaped fittings. Like the Renogy brackets ($3 each).

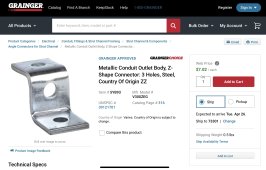

The uni and super strut versions are more $ (see below).

I need around 250 of these things and I’m thinking there is a better way or cheaper source.

The best I can think of is aluminum z-bar. A lot of work but much cheaper.

Strangely, I get a ton of hits from the UK and Australia when I search for z-fittings. But very little in the US.

Any ideas for getting big bags of 100 hot dipped Z brackets (2 or 3 hole) for cheap? I feel like my google fu sucks.

Thanks!

What I need are a bunch of Z shaped fittings. Like the Renogy brackets ($3 each).

The uni and super strut versions are more $ (see below).

I need around 250 of these things and I’m thinking there is a better way or cheaper source.

The best I can think of is aluminum z-bar. A lot of work but much cheaper.

Strangely, I get a ton of hits from the UK and Australia when I search for z-fittings. But very little in the US.

Any ideas for getting big bags of 100 hot dipped Z brackets (2 or 3 hole) for cheap? I feel like my google fu sucks.

Thanks!