The batteries were just purchased a month or so ago..... how new do they have to be? Is there any way to get a version number or something that lets me know what I have? BTW: For something like SCP, the indication needs to persist till the battery is turned back on.... not just indicate a short while it is happening.

Can the firmware be updated to add this feature?

Exactly.

Thank You

Again..... What does "newer version BMS" mean? These batteries are brand new. How do I tell what version I have and what is the new version?

BTW: I have the High cycle count issue. Does that mean I have a corrupt flash? Is there a way to reset it? This news is kinda disturbing because SOK also instructs us to run the battery all the way down

twice to train the SOC. Is this action creating a risk of corrupting flash?

BTW: The only reason I did not add a better way to train the SOC was that

@HighTechLab said it was being worked on.

Thank you for pushing. These 100Ah Batteries were chosen because they are physically sized to replace the RV Lead Acid batteries quite nicely. Very little had to be done to make them fit. A lot of RVs are stored more than they are used so a storage mode would be an ideal match for the use case.

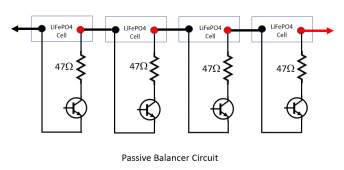

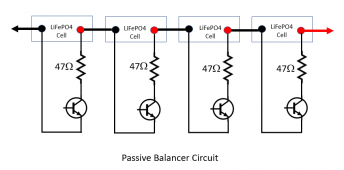

![2022-08-25 13_56_37-Eeschema — SOKBMS2022v6.sch [_] — C__Users_Dan_Documents_SOK_2022BMS_SOKBM...png 2022-08-25 13_56_37-Eeschema — SOKBMS2022v6.sch [_] — C__Users_Dan_Documents_SOK_2022BMS_SOKBM...png](https://diysolarforum.com/data/attachments/108/108378-4c5d6f854a0f7ee2dcef9554f54670c1.jpg)