Hedges

I See Electromagnetic Fields!

- Joined

- Mar 28, 2020

- Messages

- 20,695

Arc fault may have a sensitivity adjustment.

Do you have a scope, ability to see what's happening on PV wires?

I think PLC is pulses of injected current, so pickup with a CT, or more likely a CT you make with suitable toroid, might be the way. (I've observed attenuated signal at 20 kHz when trying to measure inrush with CT; what frequency is PLC from Tigo?)

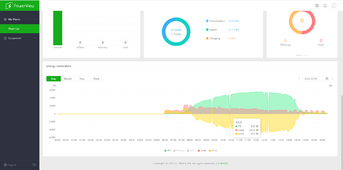

I'm viewing TIGO monitoring to try and figure out why I'm getting arc faults. I'm seeing a strange phenomenon. 5 minutes before the Sol-Ark reports an arc fault the optimizers stop reporting data. I have 1 minute data resolution with the premium monitoring service..

Do you have a scope, ability to see what's happening on PV wires?

I think PLC is pulses of injected current, so pickup with a CT, or more likely a CT you make with suitable toroid, might be the way. (I've observed attenuated signal at 20 kHz when trying to measure inrush with CT; what frequency is PLC from Tigo?)