Your equipment list looks great - I bookmarked the battery monitor as a good alternative to the one I posted

I'm not sure how to determine what the inverter draws. 24v, 2500w, 120vac. Probably none of those, knowing me. I'm looking up solar cable and I find 10 and 12 AWG. What am I missing? I'm so close to putting it all together.

2500w/24v = 104amps (it would be twice this at 12v)

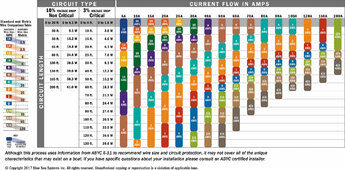

I tend to use the windy nation chart - it is 105c welding wire - Pretty much the same chart as

@Rednecktek posted.

Welding wire is very fine stranded rubbery sheath - won't bunch when bending a tight turn but won't hold its shape when released

Battery wire is fine stranded - Sheath is a chemical resistant thermoplastic - holds its shape a bit more

THHN has larger strands or is solid - usually multiple layers, PVC and thermoplastic - holds shape very well, but the sheath bunches when bent tight

Solar/PV wire is in a very bendable sheath that is also UV and water resistant so it won't rot away in a few year. It won't allow water inside to corrode the conductors. It is worth the cost if used above ground or not in conduit.

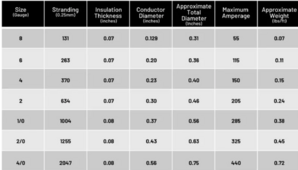

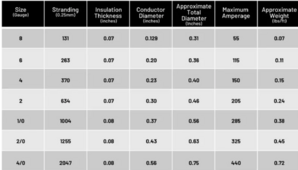

Current carrying capacity of wire is the cross sectional area of the copper - for all types the amount of copper should be the same. The ability to shead heat - solid works best and fine stranded the worst. The happy medium is course stranding like THHN or battery wire.

Wire sheaths are rating for the temperature they can run at and not have issues- for this sort of thing I always buy 105c

Standard THHN like they carry at home depot is typically 90c, but you can get 105c or higher.

Wire sheaths are also rated for voltage blocking - i.e. a 600v rating (pretty standard) will not short to another conductor even if bare unless voltage exceed 600v.

The higher the strand count the more bendable it is. So working in tight spaces it makes sense to use welding wire in my project.

Normally you would also look at voltage drop over length. For our short lengths it seldom matters for anything but the solar array cables. Wire is rated in Ω per 1000ft. To small a wire and the voltage at the other end drops giving you a brownout.

Windy nations' chart

There is a lot of good information here.

Windy Nation Inc

www.windynation.com

So you have 105amps from the inverter - if you ever want to go up in inverter size it is simpler to overdo the wire size.

105a * 1.20 = 126amps

So pick a wire - technically 4 awg welding wire will handle the current - but is your wire going to be in free air or enclosed? I tend to figure out my need and go up one size because I don't like the idea of hot wire under any circumstances. So I would pick the 2 awg wire for this project.

If you don't have and don't want to have crimpers for the larger cables (good ones cost $$$) then you can order premade to length cables from someplace like this. This way you know you have good main cables with lugs crimped properly.

www.batterycablesusa.com

Now for the fuse - you can fuse for 20% over 126 amps or fuse for 20% over 150 amps. Because I oversize the wire I tend to fuse for 20% over the size required even though the wire can handle more. If your wires are long get a second fuse and use it at the inverter end. By long in this case I mean more than a couple of feet.

126amps * 1.2 = 151 amps

So in this case I would fuse at 150 amps - it is enough that it will prevent nuisance blows but low enough to blow and protect the wire.

fuse - get a spare or two

Single fuse holder and cap - I personally skip the cap and use rubber ends on all my wires to prevent shorts

Double holder -

so you can use one post with one size wire to the inverter and a second smaller fuse to another device with a smaller wire.

If you add more battery strings or batteries you would also want to add in a class T fuse. The class T has a higher AIC (arc interrupt current)

@Rednecktek recomendation on the wire to the solar panels and the configuration is spot on.

Grounding -

What isn't shown on th diagram posted earlier is the grounding system. For this you assume everything needs to be the same potential. This means 1 and only 1 ground rod driven into the earth at the cabin where the service entrance for power is. If you never had grid power there may or may not be a ground rod.

Ground rods are typically 8 to 10 foot long and driven in vertically. BUT if your soil is very rocky and bedrock is in the way you can put it in at a slant or even horizontal. If you put it in a trench, dig as deep as you can and leave just the top 4" or so above ground to attach a wire.

At any rate - the ground rod runs with bare copper to your electrical panel if you are using one. I see a ground screw on the bottom of the inverter you linked. The wire from the ground rod would need a lug then attach it here. Also you need enough wire to reach your array for grounding the frames of your panels. This wire is connected to only the frames - there should be a screw or clamp for that on each panel. If there are any other metal parts of your electrical systems (like a panel) you would tie that into the ground.

At no point do any of the DC wires, PV wires, or AC wires get tied directly to ground. With the inverter you havbe linked it would seem to be the neutral and ground are tied internally. Would be worth knowing - you can check with a meter and see if that is true - measure voltage across the ground pin (the round one) and the neutral blade (the wider one) if it is zero and doesn't waver they are tied likely tied together. Next test would be to turn things off and measure with the ohm meter the same thing - it should read zero ohms.