At least in my system, I have a manual disconnect immediately after the Class T so that I can de-energize the whole system to work on it. I view it as cheap insurance.ABYC requires a battery disconnect. I don't think that interrupting the relay coil satisfies that, but having 2 switches as I drew would.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Small Boat BMS/LFP with backup

- Thread starter rgleason

- Start date

Goboatingnow

Solar Enthusiast

- Joined

- Jul 3, 2022

- Messages

- 1,325

The single switch solution isn’t failsafe for the reason a pointed outAt least in my system, I have a manual disconnect immediately after the Class T so that I can de-energize the whole system to work on it. I view it as cheap insurance.

A simple solution is a two switch solution where the AFD terminals on the SLA are coupled via a small relay to the control lines of the main bms contactor.

This ensures any time the SLA is in circuit the relay disconnects the contactor.

That still leaves the risk of closing the manual Override switch.

Personally were I designing this , I’d simply implement the Li manual override as merely a secondary input to the contactor. The contactor should be extremely robust. Should it fail I’d simply carry a jump lead.

Goboatingnow wrote:

Blueseas shows no interest in providing this switch

As stated several times earlier in this thread, unfortunately this simple solution simply does not exist and cannot be purchased. AFD contacts disconnect around OFF.simple solution is a two switch solution where the AFD terminals on the SLA are coupled via a small relay to the control lines of the main bms contactor.

Blueseas shows no interest in providing this switch

4 way switch with RCD (relay coil disconnect)

NORMAL - Normal LFP Operation (relay coil wire is connected and BMS is operating normally)

Position 1 - LFP Bypass Relay Coil Switch (relay coil wire is disconnected) LFP is connected.

Position 2 - SLA Emergency Backup (relay coil wire is disconnected to comply with ABYC requirements) SLA is connected.

OFF & LFP Disconnect- No Batteries (relay coil wire is disconnected to over-ride the BMS)

In this situation the disconnect of the relay coil wire has to occur around Position 1, Position 2 and OFF.

The relay coil wire is only connected when the switch is on NORMAL.

Position 1 provides connection to the LFP Battery (house).

Position 2 provides connection to the SLA Battery (start).

Last edited:

Goboatingnow

Solar Enthusiast

- Joined

- Jul 3, 2022

- Messages

- 1,325

Yes using the AFD contacts via a powered relay could then invert the switch logic , so that the small relay would disable the main BMS contactor when the switch connects in the SLA, no need to dismantle the switch !Goboatingnow wrote:

As stated several times earlier in this thread, unfortunately this simple solution simply does not exist and cannot be purchased. AFD contacts disconnect around OFF.

Blueseas shows no interest in providing this switch

It’s easy to do if you accept electrical interlocking, use a standard marine battery switch with AFD , rig a powered relay ( powered by the SLA) so that the relay is “ on” via the AFD when the switch is anything other then off. , then use the NC contacts from the relay to disable the main BMS contactor.

You problem is solved. The BMS contactor cannot operate while the battery switch is at any other setting other then “ off” . This prevents the contactor energising when the switch has the SLA in circuit ( or equally when the BMS overrides is selected )

Last edited:

@Goboatingnow

I like the idea to use a small relay powered by SLA to invert the switch logic.

but this would likely result in:

NORMAL - Normal LFP Operation - relay coil is disconnected - NOT GOOD the BMS needs to operate normally)

Position 1 - LFP Bypass - relay coil wire is disconnected - GOOD

Position 2 - SLA Emergency Backup - relay coil wire is disconnected - GOOD

OFF & LFP Disconnect- relay coil wire is connected - NOT GOOD we need to over-ride the BMS)

We still have to sort a couple of things, perhaps it is as simple as making a new contactor plate that, connects in the right quadrants?

I should try to take apart my switch on the boat.

I like the idea to use a small relay powered by SLA to invert the switch logic.

but this would likely result in:

NORMAL - Normal LFP Operation - relay coil is disconnected - NOT GOOD the BMS needs to operate normally)

Position 1 - LFP Bypass - relay coil wire is disconnected - GOOD

Position 2 - SLA Emergency Backup - relay coil wire is disconnected - GOOD

OFF & LFP Disconnect- relay coil wire is connected - NOT GOOD we need to over-ride the BMS)

We still have to sort a couple of things, perhaps it is as simple as making a new contactor plate that, connects in the right quadrants?

I should try to take apart my switch on the boat.

@Goboatingnow from CF

What do you think of using a good Lithium (it isn't LiFePo, though) Jump start pack for the SLA battery engine start side? I believe it would start our Yanmar 3YM30 easily, but would it provide enough amps to provide emergency backup?

You must consider this effort to make a simple single control switch kind of futile?Nor does it make any sense to build redundancy to protect you from Li failure. That’s madness. The Li bank will be extremely reliable better then any other battery on board. If you don’t trust thd tech why Fit it.

Lithium is way way better at high current provision then any cheap SLA . Look at all those Lithium jump start packs etc.

What do you think of using a good Lithium (it isn't LiFePo, though) Jump start pack for the SLA battery engine start side? I believe it would start our Yanmar 3YM30 easily, but would it provide enough amps to provide emergency backup?

Goboatingnow

Solar Enthusiast

- Joined

- Jul 3, 2022

- Messages

- 1,325

AFD works when the switch is off , the AFD contacts are closed on all other positions@Goboatingnow

I like the idea to use a small relay powered by SLA to invert the switch logic.

but this would likely result in:

NORMAL - Normal LFP Operation - relay coil is disconnected - NOT GOOD the BMS needs to operate normally)

Position 1 - LFP Bypass - relay coil wire is disconnected - GOOD

Position 2 - SLA Emergency Backup - relay coil wire is disconnected - GOOD

OFF & LFP Disconnect- relay coil wire is connected - NOT GOOD we need to over-ride the BMS)

We still have to sort a couple of things, perhaps it is as simple as making a new contactor plate that, connects in the right quadrants?

I should try to take apart my switch on the boat.

So a little control relay will therefore powered off when the battery switch of off.

It will be on in all other positions.

The NC controls of the control relay are wired in series with the main contactor coil.

Hence switch 1 , SLA feed , relay powered on , NC contact open , bms contactor depowered

Similar in switch 2 , BMS override ( it doesn’t matter if the contactor is depowered

Switch in Off , relay depowered NC contact closed. Bms contactor again under bms control.

This achieves what’s desired an electrical interlock to prevent the bms contactor going live while the SLA is in circuit

Goboatingnow

Solar Enthusiast

- Joined

- Jul 3, 2022

- Messages

- 1,325

I would be happy to have a small portable Li jump start on board , good idea@Goboatingnow from CF

You must consider this effort to make a simple single control switch kind of futile?

What do you think of using a good Lithium (it isn't LiFePo, though) Jump start pack for the SLA battery engine start side? I believe it would start our Yanmar 3YM30 easily, but would it provide enough amps to provide emergency backup?

Thank you, I think I understand:

"OFF" is actually "Normal LFP Operation" and should be relabeled accordingly.

That is very helpful.

Now to comply with ABYC we need an "LFP Disconnect"

...or could we consider that the "SLA Emergency" also serves as the "LFP Disconnect"?

and should be labeled accordingly?

"OFF" is actually "Normal LFP Operation" and should be relabeled accordingly.

That is very helpful.

Now to comply with ABYC we need an "LFP Disconnect"

...or could we consider that the "SLA Emergency" also serves as the "LFP Disconnect"?

and should be labeled accordingly?

I have a Li jump start pack on board. Its a bigger one, and comes in at 12Ah.I would be happy to have a small portable Li jump start on board , good idea

I use it alot, mostly to quickly fill my dinghy, but also on excursions to keep my phone topped off. It will start my engine, and even the large Cummins in my brothers F250. But not regularly. Its for emergency use starting engines, and damages it after more than a few times.

Goboatingnow

Solar Enthusiast

- Joined

- Jul 3, 2022

- Messages

- 1,325

Label it as like. The functionality provides a single selector switch and electrically interlocks the contactor.Thank you, I think I understand:

"OFF" is actually "Normal LFP Operation" and should be relabeled accordingly.

That is very helpful.

Now to comply with ABYC we need an "LFP Disconnect"

...or could we consider that the "SLA Emergency" also serves as the "LFP Disconnect"?

and should be labeled accordingly?

Before I add this to the diagram, regarding the relay itself, should it be

Should it be solid state or relay coil like the heavier contactor?

I think it should be reasonably water tight or protected from corrosion too.

I am kind of getting lost in all the choices.

- 12vdc - 12vdc

- SPST (single pole single throw)

- NC (normally closed)

- Amerage? (Basically sized for the other 500a relay control wire) Found in this post here

- EV200AAANA 12/24V/500A 1618002-7 New energy electric vehicle contactor high voltage DC Relay

- High voltage relay voltage (maximum) (VDC): 900

- High voltage relay coil voltage rating (VDC): 9 – 36

- High voltage relay coil resistance (Ω): 3.14

- High voltage relay terminal switching voltage (maximum) : 900

- Built in coil economizer 1.7w hold power at 12vdc, limiting back emf to 0v

- Comments: "At the time of inclusion consumes about 3.5 A at 12 V., then drops to 0.130 A. the resistance of power contacts is 0.16 m. All the parameters match the declared passport characteristics, an excellent power contactor, I will see how it will show itself in work, if it will be possible to complement the feedback from the resistance. 02 Aug 2022 12:15 "

Should it be solid state or relay coil like the heavier contactor?

I think it should be reasonably water tight or protected from corrosion too.

I am kind of getting lost in all the choices.

Last edited:

Goboatingnow

Solar Enthusiast

- Joined

- Jul 3, 2022

- Messages

- 1,325

You are only switching the coil of the contactor relay so a simple NC contact automotive style 12 v relay capable of low voltage 7A is all you need. Cheap as chipsBefore I add this to the diagram, regarding the relay itself, should it be

Would 5 amp be ok?

- 12vdc - 12vdc

- SPST (single pole single throw)

- NC (normally closed)

- Amerage? (Basically sized for the other 500a relay control wire) Found in this post here

- EV200AAANA 12/24V/500A 1618002-7 New energy electric vehicle contactor high voltage DC Relay

- High voltage relay voltage (maximum) (VDC): 900

- High voltage relay coil voltage rating (VDC): 9 – 36

- High voltage relay coil resistance (Ω): 3.14

- High voltage relay terminal switching voltage (maximum) : 900

- Built in coil economizer 1.7w hold power at 12vdc, limiting back emf to 0v

- Comments: "At the time of inclusion consumes about 3.5 A at 12 V., then drops to 0.130 A. the resistance of power contacts is 0.16 m. All the parameters match the declared passport characteristics, an excellent power contactor, I will see how it will show itself in work, if it will be possible to complement the feedback from the resistance. 02 Aug 2022 12:15 "

Should it be solid state or relay coil like the heavier contactor?

I think it should be reasonably water tight or protected from corrosion too.

I am kind of getting lost in all the choices.

CPC1219Y-ND SSR RELAY SPST-NC 200MA 0-60V from Digikey $3.74 which is solid state. It seems that old style automotive relays are listed as "obsolete"

For the secondary NC relay on the 1-Off-2 switch to reverse the AFD operation, a Citi Automotive Sealed Relay and Switch non-latching 12vdc SPDT with coil contact rating 25a and max coil power of .64 watts (or 0.0533A), A161CS12VDC.64 for $1.91 looks like it might be ok

I also found some other Primary BMS Relay Coils - (goboatingnow found a good one earlier)

For smaller batteries, below 250a these waterproof BMS normally open relay coils from Littlefuse DCNEV250 SERIES HIGH CURRENT HIGH VOLTAGE DC CONTACTOR might be good, they have a holding current of .13a, but probably are expensive.

For batteries below 300a these Littlefield relays DCNHR250, DCNHR300 have a holding current of 0.15a

I also found some other Primary BMS Relay Coils - (goboatingnow found a good one earlier)

For smaller batteries, below 250a these waterproof BMS normally open relay coils from Littlefuse DCNEV250 SERIES HIGH CURRENT HIGH VOLTAGE DC CONTACTOR might be good, they have a holding current of .13a, but probably are expensive.

For batteries below 300a these Littlefield relays DCNHR250, DCNHR300 have a holding current of 0.15a

Last edited:

Goboatingnow

Solar Enthusiast

- Joined

- Jul 3, 2022

- Messages

- 1,325

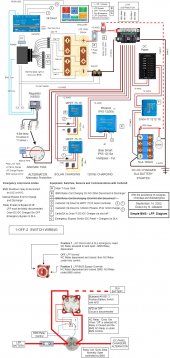

nice , very much a reference circuit

Thanks for all the help @Goboatingnow

Similar threads

- Replies

- 12

- Views

- 310

- Replies

- 44

- Views

- 2K