DyslexicDancer

New Member

- Joined

- Aug 3, 2022

- Messages

- 27

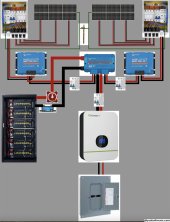

I'm setting up an Off-Grid solar power system for a Cabin in East Texas

My Main system parts consist of:

12 SunPower 330W panels (panels will be wired 2 in series)

2 solar ground mounts made from Unistrut

2 Solar Combiner boxes (1 for each solar panel mount)

2 Victron 150/45 Smart Solar charge controllers

1 Victron Smart Shunt

1 Victron Lynx Distributor

1 Growatt 3000W inverter

1 30 KW/H server rack battery

1 battery cutoff switch

2 Two Pole DC 50 Amp Breakers (Between the Charge Controllers and the Lynx Distributor)

1 Two Pole DC 125 Amp Breaker (Between the Lynx Distributor and the Inverter)

This is my current plan to wire up the system, (not shown in the ground wire from the AC Breaker box to the grounding rods)

Am I forgetting anything important or adding unneeded items?

Also I'm thinking about adding in a Cerbo GX so i can monitor this system remotely, any thoughts or opinion an adding this would be appreciated

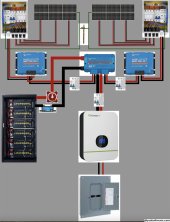

My Main system parts consist of:

12 SunPower 330W panels (panels will be wired 2 in series)

2 solar ground mounts made from Unistrut

2 Solar Combiner boxes (1 for each solar panel mount)

2 Victron 150/45 Smart Solar charge controllers

1 Victron Smart Shunt

1 Victron Lynx Distributor

1 Growatt 3000W inverter

1 30 KW/H server rack battery

1 battery cutoff switch

2 Two Pole DC 50 Amp Breakers (Between the Charge Controllers and the Lynx Distributor)

1 Two Pole DC 125 Amp Breaker (Between the Lynx Distributor and the Inverter)

This is my current plan to wire up the system, (not shown in the ground wire from the AC Breaker box to the grounding rods)

Am I forgetting anything important or adding unneeded items?

Also I'm thinking about adding in a Cerbo GX so i can monitor this system remotely, any thoughts or opinion an adding this would be appreciated

Last edited: