I'll try to show some schematics to make the problem more "visible".

Btw. I will use the wording "dirty" load for loads which interact in a negative way with the HF inverter to make some LED loads pulsing.

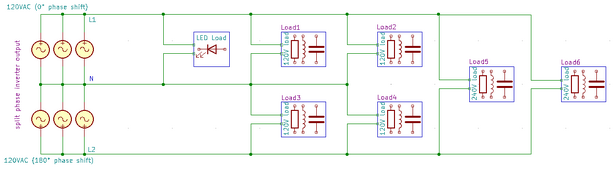

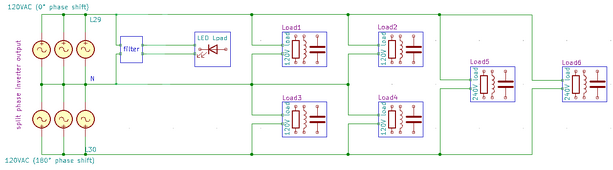

This may be a typical example situation:

There are one or more split phase inverters (in my case 3 in parallel for L1 and 3 in parallel for L2). Typically there are different type of 120V loads (Load1-Load4) distributed over the two phases and some 240V loads (Load5 and Load6) connected. The loads are a mixture of resistive, capacitive, inductive characteristics (motors, lamps, electronic equipment, etc. everything which is possible in a typical house).

Let's assume that as soon as Load2 is connected and it is a "dirty" load which causes the "LED Load" to pulse (other LED loads on the same phase may not pulse because they may have better build quality).

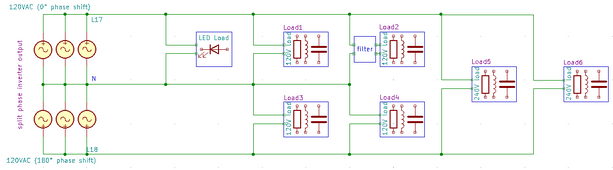

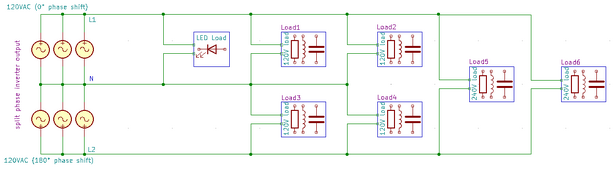

Now I ask myself if it's possible to put a filter in front of the "dirty" Load2 like shown in the following picture to stop the pulsing of the "LED Load" (to stop the 3-7Hz interference oscillation between Load2 and the HF inverters which causes the "LED Load" to pulse).

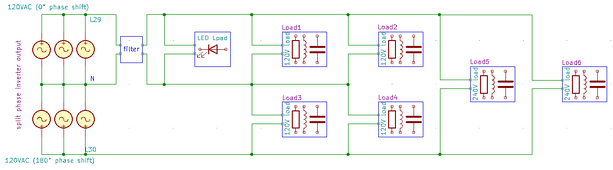

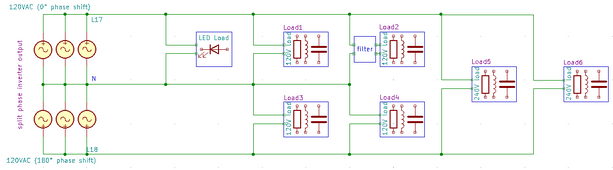

It may also possible to put a "generic" filter just at the output of the inverters to stop any kind of LED pulsing (on the same phase) from whatever "dirty" load it may be produced, like this. This would be the optimal solution because one filter for each phase would be enough instead of one filter per "dirty" load.

I'm pretty sure that any "dirty" load is a bit different but because the pulsing is always between about 3-10 Hz, a generic filter may be possible - but not sure.

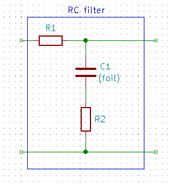

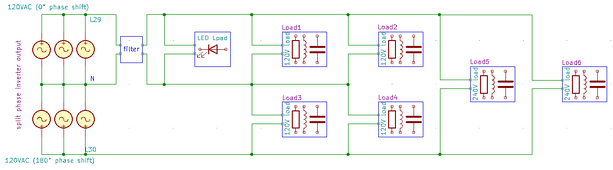

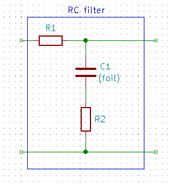

About all your suggestions and answers, I'm still not really sure how an RC filter in this situation should look like. I assume this picture...

So to summarize some of your comments, the Capacitor C1 must not be an polarized (because of AC) and it should be a foil type to be reliable and longer lasting. The Resistor R1 should have an extremely low value or it should better be 0Ω because it would heat up with higher loads. I think R2 would be required to reduce the current through the capacitor.

Which values would you choose for C1 and R2 (and possibly R1 if not zero)?