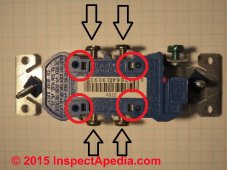

Well it happened, I don't know my own strength and I also didn't realize the torque numbers in the Victron manual are MAXIMUM values... Thankfully we have the equipment and Skilled individuals to fix the mistake in house, and not need to RMA the equipment. As you can see the Neutral stud was just a plated Brass bolt that was soldered to the board, and it only took a second to snap it into oblivion. (this pic was after we attempted to just back the stud out, which is clearly impossible once you remove the fans and investigate the assembly)

Step 1:

Desolder the Broken bolt. We used a Hakko Desoldering station, some flux, and a Hot Air Bath to add some heat to speed things up a bit.

STEP 2:

Repeat removal process, and then Re-Solder the Donor bolt into the Neutral position.

Step 3:

Re-Assemble, and test:

I hope my mistake can help someone in the future. I was unable to find the exact bolt on the usual hardware supplier sites, but I imagine it is out there, if you are using both AC inputs and both AC outputs.

This is not for the faint of heart,and I do not think you could easily remove this bolt with solder wick, It really requires a de-soldering station with constant vacuum.

Step 1:

Desolder the Broken bolt. We used a Hakko Desoldering station, some flux, and a Hot Air Bath to add some heat to speed things up a bit.

STEP 2:

Repeat removal process, and then Re-Solder the Donor bolt into the Neutral position.

Step 3:

Re-Assemble, and test:

I hope my mistake can help someone in the future. I was unable to find the exact bolt on the usual hardware supplier sites, but I imagine it is out there, if you are using both AC inputs and both AC outputs.

This is not for the faint of heart,and I do not think you could easily remove this bolt with solder wick, It really requires a de-soldering station with constant vacuum.