robbob2112

Doing more research, mosty harmless

It has been noted on the forum by a few that you can 'double stack' the ring terminals, if you need to. I prefer to use a long enough bus, that each inverter has it's own stud. If you ever need to do work on the system, you can remove a single cable without affecting other units if they are each on separate studs.

Stacking ring terminals is bad in general and only if you MUST do it would I. If you do it, don't stack more than two together and put the highest current draw next to the bus bar. I am asssssuming that the one in Will's video that looks double stacked is actually one on the front and one on the back of the bar.

Either of these would be great. I would get the 8 stud version in case you ever decide to expand. Solar is addictive.So maybe these and I’m good?

Or these for a bit more with a plastic cover…too bad I can’t find a six stud.PowerBar 600A BusBar - Eight 3/8"-16 Studs - Blue Sea Systems

Provides compact high-amp busing.www.bluesea.com

Victron 600A Bus Bar 4-Stud/8-Stud | Current Connected

Efficiently distribute high current and connect batteries or DC equipment with the Victron 600A Bus Bar. Durable, reliable, and versatile.www.currentconnected.com

What is your logic going from 4/0 to 2/0? Is the length of 2/0 very short? It's seemed from one post that this was a situation of one battery and two inverters? If so, that would be an explanation.

It is, one battery bank and two inverters setup as split phase from what I can tell.

For me would I do

Inv1-inv2-battery-inv3-inv4

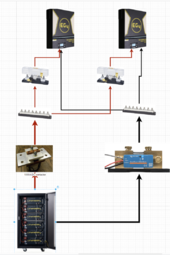

I would use something like the attached initially and you can add an extra pair of inverters to the side of each of the existing ones. Heavy lines are 4/0 and lighter lines are 2/0. The contactor acts as a switch to turn off the battery. You do need the rest of the parts for it, basically a small switch to activate it, power that isn't connected to the battery, and wiring of the appropriate size. Something like 18awg generally. I went with a contactor verse breaker because I knew it would handle the current and if you are just doing a switch why have a breaker. Also if you grid tie you can use an external switch as the cutoff for the battery bank.

Buy good wire, pure copper welding wire. Windy nation is good and I have also bought wire from shirby. For this application the finer stranded the better and high strand count is great. There are other reputable vendors but a lot will sell copper clad aluminum (CCA) which doesn't have nearly as high a current capacity.

Also make sure you have a good crimper for this, if you want to grid tie it must have the awg number imprinted into the lug when you crimp it. I personally favor the Temco hydraulic crimper. There are others that work as well.

And when you crimp the correct size wire in the correct size lug with the correct size crimper it comes out beautifully. If you crimp and there are wings sticking out something is not the correct size.

Quality lugs cost - get Temco or Ancor --

91066 Cable Lug Battery Terminal Ring 2/0 AWG Stud Size 5/16 Inch

Cable Lug Battery Terminal Ring 2/0 AWG Stud Size 5/16 Inch made from pure electrolytic copper and tin plated to resist corrosion. The heavy duty crimp connectors are top quality wire connectors.

OR just figure out the size cables you need and length and lug endsfor each and windy nation will make them to order. When I was pricing things I figured out my break even was about 6 cables made.

Make sure to read the specs on the breakers and the curves for your voltage to see how many DC amps it will take to trip it. There are a number of examples in the 'up in smoke' where the breakers never tripped dispite home built battery meltdown and resulting fire. They are good switches but not so good at tripping

Attachments

Last edited: