sunshine_eggo

Happy Breffast!

I’m past my knowledge here as well.

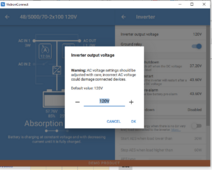

I thought with two Quattros I would run two lines (L1 and L2) at 120 volts each. Plus a neutral and a ground for 4 wires total.

I don’t think I understand how two Quattros and split phase works. In the short term, I was going to use one Quattro and see how it goes.

@sunshine_eggo Would you mind shedding some light? I’ve looked at the Victron info and the Victron forum but am still unclear.

I have two Quattros working in split phase. Q1 provides L1-N-G connections and Q2 provies L2-N-G connections. N and G are common between them. The N-G bond is provided ONLY in the L1 inverter.

With one quattro, you are limited to 120V, L-N-G.

Anything unclear?