Agreed and I would believe in that for splicing two clean straight solid wires. But for 12 awg stranded, my mind just imagines the set screw twisting them up or a couple hairs ending up straddling the screw instead of compressed by it.

Is the screw wider than the barrel of the connector so they can't end up either side of it?

Haven't had either of those problems.

Screw is just as wide as ID. So far they've worked pretty well for me. Sometimes have difficulty unscrewing cap if stuffed with wires to setscrew drags on it.

I think we're supposed to twist wire together before putting in connector. I don't at least for lab use. With widely varying wire size that isn't always secure.

Comes with a plastic tool to hold small or large brass connector while you tighten screw.

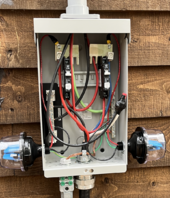

I haven't looked thoroughly, but I believe those are not usually both 600v rated and UL listed/rated. In my case these are for inside a weatherproof box like this with a gasket sealed cover plate:

View attachment 208891

That's how I transition from conduit to PV wire. Glands available with 2, 4, other number of holes in insert to seal to wire. If wires can enter through another hole on bottom, then drip proof and seal not so important.

Also PVC boxes. My surface mount exterior conduit was originally PVC until a later inspector said not for exposed horizontal runs, so I redid with rigid.

Call me stupid but I'd probably just use wire nuts. They're rated for it

I did originally.

Later realized SMA manual said not to use them. Concern was arcing causing failure of inverter.

Not sure they're any more subject to coming lose and arcing than others.

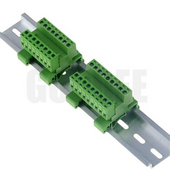

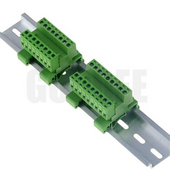

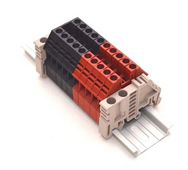

A few more connector types. DIN rail, more convenient in a combiner box.

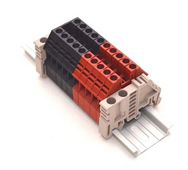

There are also some that work similar to Wago but with screwdriver in slot to spring open, rather than a plastic lever. Used in some SMA inverters.

I tend to favor connectors with wire to wire compression or heavy barrel, rather than the ones with sheet metal spring.