intentional complex speak

That's the 'problem' with research: papers are written with a target audience in mind, and in this case, it's other researchers in the area - and they assume a level of understanding (including the math and terms) relevant in the field. This is the same in my fields like cryptography and nuclear radiation. Outsiders might think it's intentionally obtuse, but it really isn't.

The thing is: do do this properly, you have to master the math that makes it work. That's why for example people on forums on radiation detection don't respond well to people who don't grasp the physics and math behind it - no matter what idea you have for a new detector. With the current climate on scientific indifference and 'who needs experts' mentalities, or just general disregard for basic science in favor of opinion (especially in online forums and communities, including this one at times) I don't blame them.

We had people on this forum come in wanting to build some complex system without even a modicum of interest in learning the math in order to do a basic power audit, or complete disregard for the use of correct units, mixing Watts, Amp Hours, Watt Hours, etc. like no tomorrow - who then get angry at you for pointing out that units matter. It gets really tiring, real fast.

Ok, this became more of a rant... sorry, back on topic.

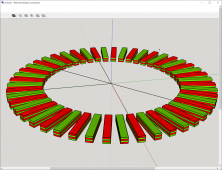

how much area the blades have in relation to the swept area of the turbine

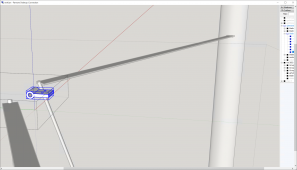

The swept area of a vertical-axis wind turbine:

A = π d h

Where d = diameter of the rotor and h = height of the rotor

If you design a rotor based on the above (let's call it a design goal since you want to maximize this), you get a swept area for a 4 meter turbine (let's assume 2 meter high) of:

A = 25m² or thereabout.

The area of the blades is directly related to this, but depends on if you have two, three or more blades.

My question is however: why do you need it? If you build this in something like SolidWorks, this is not independent of the overall design of your swept area. What I mean is: the swept area, together with the choice of amount of blades, drives the area of the blades.